P68 VARIANTS SERVICE INSTRUCTION No. 99

advertisement

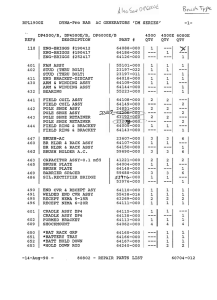

vulcanair spa via g. pascoli, 7 80026 casoria (na) – italia Tel +39 081 5918111 Fax +39 081 5918172 info@vulcanair.com www.vulcanair.com P68 VARIANTS SERVICE INSTRUCTION No. 99 Design Organisation Approval No. AS-SI/14/001 dated 15 May 2014 SUBJECT: PROPELLER ELECTROTHERMAL DE-ICING SYSTEM – BRUSH BLOCK ASSY RELOCATING 1. GENERAL 1.1 AIRCRAFT AFFECTED All P.68C-TC and P.68TC Observer aircraft up to s/n 399. 1.2 PURPOSE To supply instructions for the relocating of the brush block assy of the propeller electrothermal de-icing system when a new engine, installed in replacement of the previous one, includes a new crankcase design which interferes with the brush block assy in the actual configuration (refer to Fig. 1). 1.3 DESCRIPTION The modification consists in the replacement of the existing support arm p/n 7.8085-2 with the new one p/n 7.8085-3, and in a simple drilling operation to be carried out on the concerned existing baffle to allow the installation of the existing brush block assy mounting bracket p/n 7.8085-1 by means of existing attaching parts. 1.4 MAN-HOURS REQUIRED Time necessary for the application of this Service Instruction is estimated as 2 man-hours. 1.5 SPECIAL TOOLS No special tool is required. First Issue dated 15 May 2014 Page 1 of 7 Vulcanair S.p.A. Service Instruction No. 99 1. GENERAL 1.6 1.7 VARIATION IN WEIGHT AND BALANCE This change does not involve variations in Weight and Balance data. ELECTRICAL SYSTEM LOAD Not applicable. 1.8 REFERENCE DOCUMENTS - Applicable Maintenance Manual for aircraft type. - Applicable Parts Catalogue for aircraft type. 1.9 PUBLICATIONS AFFECTED - Applicable Parts Catalogue for aircraft type. - Applicable Maintenance Manual for aircraft type. 1.10 MODIFICATION TO BE CARRIED OUT BY Vulcanair Part 145 or other Certified Maintenance Facility. First Issue dated 15 May 2014 Page 2 of 7 Vulcanair S.p.A. Service Instruction No. 99 2. WORK PROCEDURE WARNING This work procedure calls for the use of substances and/or procedures that may be injurious to health if adequate precautions are not taken. This document refers only to technical suitability and in no way absolves the Operator from statutory and other legal obligation relating to health and safety at any stage of manufacture or use. NOTE The following instructions refer to only for the relocating of the brush block assy of the propeller electrothermal de-icing system. For its complete installation procedure and the required tests to be performed refer to the latest applicable revision of the manufacturer’s pertinent technical publication. Refer to Figure 2 and 3 for the Brush Block Assy PREMODIFICATION and POSTMODIFICATION installation layout, respectively. 1. First of all, it is necessary to install the existing engine baffles on the new engine, then trim and adjust the concerned baffle to avoid any interference with the new engine crankcase. 2. Referring to manufacturer’s pertinent technical publication, reposition the brush block assy p/n NOR7.479-14 together with the mounting bracket p/n 7.8085-1 and the new support arm p/n 7.8085-3 on the engine baffle and the engine crankcase as shown in Figure 3, aligning the brushes with the slip ring surfaces as required. Lock the brush block assy/mounting bracket/support arm group temporarily in place. 3. Drill 3.5 mm diameter No.2 holes on the engine baffle, copying from the existing ones on the mounting bracket. Remove the brush block assy/mounting bracket/support arm group. 4. Deburr the holes. Clean all the reworked surfaces with Methyl-Ethyl-Ketone or equivalenmt cleaning solvent, then treat them with alodine 1200 (MIL-C-5541). 5. Reposition and install the brush block assy/mounting bracket/support arm group on the engine baffle using the proper two removed screws, and on the engine crankcase using the concerned existing bolt. 6. Referring to manufacturer’s pertinent technical publication, perform the correct radial and fore and aft brush block assy alignments as required, then tighten the relevant attaching screws. 7. Restore all the electrical connections to the brush block assy and, when you have completed all the engine installation, check the propeller electrothermal de-icing system for correct operation. 8. Record application of this Service Instruction in the Aircraft Log-Book. First Issue dated 15 May 2014 Page 3 of 7 Vulcanair S.p.A. Service Instruction No. 99 3. MATERIALS REQUIRED FOR THE MODIFICATION Item 1 Description P/N 7.8085-3 Support Arm Q.ty 1 Commercially available materials required but not included in the Kit: - Methyl-Ethyl-Ketone or equivalent cleaning solvent. - Alodine 1200 (MIL-C-5541). First Issue dated 15 May 2014 Page 4 of 7 Vulcanair S.p.A. Service Instruction No. 99 Fig. 1 Differences between the previous and the new engine crankcase design in the concerned area First Issue dated 15 May 2014 Page 5 of 7 Vulcanair S.p.A. Service Instruction No. 99 Fig. 2 Brush Block Assy Installation layout (PREMODIFICATION) First Issue dated 15 May 2014 Page 6 of 7 Vulcanair S.p.A. Service Instruction No. 99 Fig. 3 Brush Block Assy Installation Layout (POSTMODIFICATION) First Issue dated 15 May 2014 Page 7 of 7