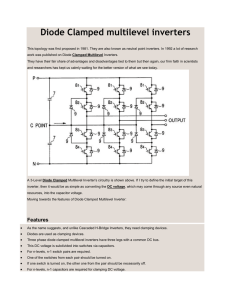

developing and investigation of a diode clamped three level inverter

advertisement