GO1 PASSIVE GALVANIC SEPARATION

advertisement

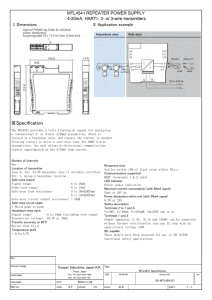

GO1 PASSIVE GALVANIC SEPARATION USE The galvanic separation is designed primarily as an input interface for data acquisition monitoring systems, control systems, control automats etc. It can be used wherever it is necessary to galvanically separate a 4 – 20mA current loop so that no undesirable influencing of input circuits of evaluation systems occurs and, at the same time, perturbing influences of industrial environment are suppressed. The separation can have a single or double channel. The galvanic separation input and output are passive, i.e. without internal power supply. The power source is the 4 – 20mA current loop. CHARACTERISTICS The GO1 passive galvanic separation has the following basic properties: • 3700Vef insulation between the input and output circuits, • passive circuit input and output, • analogue signal transfer via a linear optical element, • transfer error better than +/-0.2%, • single-channel or double-channel separation in one device, • easy installation and connection, • standard plastic box for DIN rail mounting. FUNCTION The GO1 passive galvanic separation functions as a linear passive 4 – 20mA current loop separator, which means that it needs external power supply for its operation by means of an input and output current loop. The voltage drop at the input terminals is proportional to the passing current IVST (voltage drop = 3.6V DC + IVST x 25Ω). The maximum voltage drop is approximately 4.1V DC at 20mA. The output circuit requires an active power supply of min. 9V DC. Zero and range correction can be performed within a +/-10% range by means of built-in trimmers for each channel separately. For the double channel variant, two independent galvanic separations are installed in one device. DESIGN The device is built in a standard plastic box with a width of 22.5mm, designed for DIN rail mounting. A type label with parameters and a label with a description of galvanic separation terminals are located on the side of the box. On the bottom and top sides of the box (on the side with relevant terminals) there are two trimmers for zero and output signal range correction – regulation within a +/-10% range (see figure 2). All signals are connected to a screw terminal block on the bottom or top side of the box. For connection and description of terminals see Fig. 1. To each terminal, a wire with a maximum cross-section of 2.5mm2 can be connected. MOUNTING AND ACTIVATION INSTRUCTIONS • Mounting The galvanic separation is mounted on a standard DIN rail (the box is equipped with a universal fixture for several DIN rail types). • Connection All signals are connected to a numbered terminal block on the top or bottom side of the box (fig. 1). The connection of terminals is indicated on the side label. Output circuits of several galvanic separators can be connected in parallel to one power supply unit at the same time. The number of connected devices is limited only by the output power of the power supply unit. • Putting into operation The device is ready for operation with guaranteed parameters after the supply voltage has been connected and after the necessary settling time (approx. 5 min) has passed. • Operation and maintenance The device does not require maintenance. Recommended functional parameters control 1x per year. • Warranty and repairs In case of breakdown or deviation from stated parameters, the device must be returned to the sales organization in terms of warranty or after-warranty repair (see the warranty certificate). 1st CHANNEL CONNECTION DIAGRAM Terminals A, B …… input analogue signal Terminals D, E …… output analogue signal 2nd CHANNEL Terminals K, L …… input analogue signal Terminals G, H …… output analogue signal Fig. 1: Connection of the GO1 galvanic separation terminal block. P1 …… displacement ZERO P2 …… displacement RANGE Correction elements for the 1st channel - from the A to F terminals side Correction elements for the 2nd channel - from the G to M terminals side Fig. 2: Description of elements for the GO1 galvanic separation output correction. Fig. 3: Recommended connection of the GO1 galvanic separation. OPERATING CONDITIONS • Working environment temperature: • Power supply – input: – output: • Settling time: • Service type: 0°C to +50°C active signal 4 – 20mA (volt. drop = 3.6V DC+IVST+25Ω) 9…36V DC approx. 5 min permanent TECHNICAL PARAMETERS (Ta = 23°C) • Input signal range (IVST): • Output signal range (IVÝST): • Signal transfer characteristic: • Signal transfer error: • Temperature coefficient: • Test voltage input - output, between channels: • Operation voltage input - output, between channels: • Protection: • Dimensions: • Weight: 4…20mA 4…20mA linear +/-0.2% of range +/-0.2% of range at 1°C env. temperature change 3700Vef/1 min 3700Vef or DC IP20 22.5 x 75 x 100mm (w x h x d) approx. 150g ORDER CODE Prefix a b c GO1 a / b – c No. Input 4 Output 4 Version – number of channels 1 2 Name Meaning 4 – 20mA 4 – 20mA single-channel (1 x GS) double-channel (2 x GS) CUSTOMER INFORMATION • This catalogue sheet serves as an accompanying document for the product • Send your orders (device type specification see order code) or questions to the below-mentioned address. Dodávky automatizace, spol. s r. o., 1. máje 34/120, 706 02 Ostrava-Vítkovice, Czech Republic, tel.: +420 596 600 680, (111), fax: +420 596 600 116, (115), e-mail: mikroelektronika@daas.cz