Mass Production The basic facts

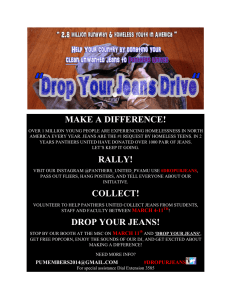

advertisement

Mass Production Mass production (also called repetitive flow or volume production) is when very large numbers of identical products are made continuously over a long period if time. The products are not too complicated and can be made cheaply (e.g. tights). The basic facts Straight line production – each operator does the same task repeatedly before passing the work along the production line. Machinery often runs 24 hours a day, 7 days a week. Unskilled or semi skilled workers: workers are skilled in one operation; they are paid according to the numbers of pieces they stitch. This is called piece work. Requires high investment to buy machinery, but this is off-set against long production runs which reduces costs overall. Large numbers of specialist equipment are required; each machine does a specific job. It is expensive to alter styles and reset machinery. Materials and components can be bought in bulk, thus reducing costs and making the end products significantly cheaper for the customer. Very large quantities of products can be produced within a short time scale. This also reduces costs. Manufacturing in cheaper labour countries. Example: Jeans As the jeans move along the assembly line, each machinist works on a specific stage of production: such as stitching a seam, inserting a zip or attaching the waistband. When the jeans have passed through all the stages, they are complete. The film that follows this document takes the viewer through the stages needed to manufacture a pair of jeans. It starts with the mass production of the cotton……….. Advantages of mass production Bulk buying of materials and components reduces costs, which is then passed on to the consumer. The style of designer clothing can be replicated easily, making designer ‘trends’ available and affordable for the mass market. Machinists can earn good money – they are paid according to how many pieces they sew. Steady employment for workers because demand for the products is high. Profit margins for manufacturers are quite high because the products are produced cheaply. Disadvantages of mass production If there is a breakdown on one part of the assembly line, production grinds to a halt. It can be highly repetitive and boring for the workers. Warehouse space is needed to store components and materials ready for production. This can increase costs. It can be expensive for the manufacturer to alter production lines. Quality of products is not always guaranteed! Thousands of the same products available in the market place. Just-in –time production (JIT) With this manufacturing system stocks of materials and components are regularly delivered to the factory just before they are needed for manufacturing the products. They are used immediately. Advantage of JIT It is not necessary to have large warehouses to hold stocks of materials etc. prior to manufacture. Lower production costs. Fast, efficient and high quality performance. Disadvantage of JIT If deliveries are delayed, production is brought to a standstill. This adds costs for the manufacturer. Mass produced textile products The items shown here are typical of mass produced textile products. Although different colour ways are produced the basic shape of the product is unchanged and therefore the machinery for the production run remains the same. Styles vary little over several years and are some times considered classic styles. Several plies of fabrics are laid on to a cutting table and then with the use of a computer controlled cutting machine individual template pieces are cut out. Machines like this are commonly used throughout the textile manufacturing industry particularly in mass production