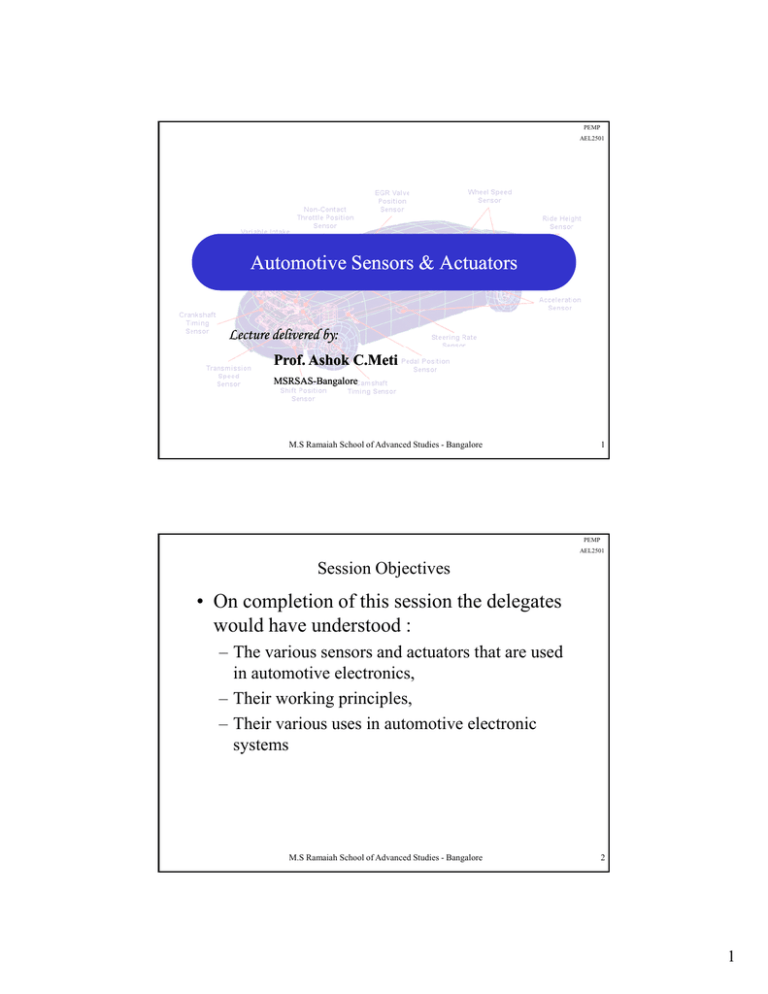

Automotive sensors and actuators

advertisement

PEMP AEL2501 Automotive Sensors & Actuators Lecture delivered by: Prof. Ashok C.Meti MSRSAS--Bangalore MSRSAS M.S Ramaiah School of Advanced Studies - Bangalore 1 PEMP AEL2501 Session Objectives • On completion of this session the delegates would have understood : – Th The various i sensors andd actuators that h are usedd in automotive electronics, – Their working principles, – Their various uses in automotive electronic systems M.S Ramaiah School of Advanced Studies - Bangalore 2 1 PEMP AEL2501 Topics • • • • • • Introduction to automotive electronics Automotive sensors and actuators Selection criterion Different types of sensors Actuators A case study – Honda City car M.S Ramaiah School of Advanced Studies - Bangalore 3 PEMP AEL2501 Automotive Electronics - Introduction • Over the past 30 years, vehicle electronic systems have changed significantly. • Mechanical systems are continue to be controlled with electronic systems. • The evolution of microcontroller and sensor technology is allowing automobile industry to create complex systems that can provide higher levels of vehicle control and safety. y design g is • The overall ggoal of electronic embedded system to balance production costs with development time and cost. M.S Ramaiah School of Advanced Studies - Bangalore 4 2 PEMP AEL2501 M.S Ramaiah School of Advanced Studies - Bangalore 5 PEMP AEL2501 Automotive Sensors & Actuators • Automotive manufacturers are continuously increasing the use of electronics systems to– improve vehicle performance – Safety – passenger comfort. • Sensors and actuators integrated with automotive control computers help optimize vehicle performance while improving p g reliability y and durability. y Sensor-- Input Sensor Microcontroller Actuator-- Output Actuator M.S Ramaiah School of Advanced Studies - Bangalore 6 3 PEMP AEL2501 Measurement System ELECTRICAL OUTPUT MEASURED QUANTITY SENSOR SIGNAL CONDITIONING SERIAL OR PARALLEL VOLTAGE A/D CPU M.S Ramaiah School of Advanced Studies - Bangalore 7 PEMP AEL2501 Selection Criteria • What is to be measured • Magnitude, range, dynamics of measured quantity • Required resolution, accuracy • Cost • Environment • Interface Requirements: – Output quantity (voltage, current, resistance,…) – Sensitivity – Signal conditioning – A/D requirements (#bits, data rate) M.S Ramaiah School of Advanced Studies - Bangalore 8 4 PEMP AEL2501 Thermistors • Commonly used for temperature measurement on vehicles. • They are made out of semiconductor materials such as cobalt or nickel oxides. • Change in temperature causes change in resistance of the thermistor. • Most of the thermistors are of the negative temperature coefficient (NTC) type • Resistance range – Several Kilo Ohms at 0oC to a few hundred Ohms at 100o C. Thus it can be more sensitive. M.S Ramaiah School of Advanced Studies - Bangalore 9 PEMP AEL2501 • Important factors for accurate measurements: – Supply must be constant – Current through the thermistor should be negligible ( I.e. No heating effect) • These devices are commonly used as sensors for– – – – Air intake Battery Engine and transmission temperature Air conditioning and internal/external environmental temperature – Oil and gas temperatures. M.S Ramaiah School of Advanced Studies - Bangalore 10 5 PEMP AEL2501 Temperature sensor • Application Engine management • Function Registration of temperature of coolants, l fuel f l andd air i • Installation Engine block, coolant circuit, air-intake tract • Sensing principle NTC technology (hot conductor, negative temperature coefficient) • Technical data – Temperature range: -40°C...+150°C – Time constant: 5 s...44 s (depending on type) – Accuracy: ± 0.8 K at 100°C ±1.5 K at 20°C M.S Ramaiah School of Advanced Studies - Bangalore 11 PEMP AEL2501 Thermocouples • When two dissimilar metals are joined together, the thermocouple junction is formed. • Among the two junctions used, one of the junctions is kept at a constant known kno n temperature temperat re where here as the other at the temperature to be measured. • Ex: 70% platinum & 30% rhodium alloy known as B Type , Has a range of 0 15000C. • Used for measuring Exhaust Gas and turbocharger temperatures in a vehicle. M.S Ramaiah School of Advanced Studies - Bangalore 12 6 PEMP AEL2501 Magnetic Sensors Variable Reluctance (VR) Sensors • Used mainly for speed and position measurements of rotating members. ( Ex: crank shaft speed p and position p sensing) g) • The variable reluctance sensor is an electromagnetic device consisting of a permanent magnet surrounded by a winding of wire. wire • The sensor is used in conjunction with a ferrous target that either has notches or teeth. • Rotation of the target wheel near the tip of the sensor changes g the magnetic g flux, creatingg an flux, analog voltage signal in the sensor coil. • Though the voltage may vary depending on the speed of rotating member, the frequency is used for measurement. M.S Ramaiah School of Advanced Studies - Bangalore 13 PEMP AEL2501 • A common method of converting this signal into a useful signal for interfacing with ith other th di digital it l circuit i it is i by b using a Schmitt trigger circuit. • Another method is by using a quenched oscillator circuit as shown in the figure. This circuit has good resistance to interference interference. M.S Ramaiah School of Advanced Studies - Bangalore 14 7 PEMP AEL2501 • Typical Applications: – Ignition system engine speed and position – Speed sensing for electronically l t i ll controlled t ll d transmissions – Vehicle speed sensing – Wheel speed sensing for ABS and traction control systems M.S Ramaiah School of Advanced Studies - Bangalore 15 PEMP Hall Effect Transducers AEL2501 Principle: • If a certain type of crystal is carrying a current in a transverse magnetic field, then a voltage will be produced at right angles to the supply current. current • The magnitude of the voltage is proportional to the supply current and to the magnetic field strength. • With proper design, design the output of this device is a square wave. • The principle is used in distributors and also to detect the current flowing on a cable. bl M.S Ramaiah School of Advanced Studies - Bangalore 16 8 PEMP AEL2501 Variable resistance • These sensors are mainly used for sensing larger change in position. position – Example: The throttle position sensor, which is a potentiometer. • It is supplied with a stable 5 Volts DC. • The wiper is driven by the throttle shaft shaft. Thus , the voltage from the wiper contact will be proportional to the throttle position. position • In many cases,throttle potentiometer is used to indicate the rate of change of throttle position position. This information is used in implementing acceleration enrichment or over-run fuel cut-off. M.S Ramaiah School of Advanced Studies - Bangalore 17 PEMP AEL2501 Available in clockwise and anti-clockwise Printed Circuit Resistors M.S Ramaiah School of Advanced Studies - Bangalore 18 9 PEMP AEL2501 Accelerator-pedal module • Application Engine management • Function Registering the driver's wishes (d (demand d for f torque)) • Installation Passenger compartment • Sensing principle Hall effect or potentiometer • Technical data – Supply voltage: 5 V – Measuring M i range: customer-specific t ifi pedal d l travel t l 40 mm ... 80 mm – Temperature range: -40°... +80°C – Output signal: analog M.S Ramaiah School of Advanced Studies - Bangalore 19 PEMP AEL2501 Pressure sensor • Application Engine management • Function Barometric pressure measurement • Installation Printed circuit board (PCB) • Sensing principle Silicon micromechanics with integrated evaluation circuit • Technical data – Measuring range: 60 kP... kP 115 kPa – Analog output: 2.37 V ... 4.54 V – Temperature range: 40°C ... +130°C M.S Ramaiah School of Advanced Studies - Bangalore 20 10 PEMP AEL2501 Low-pressure sensors for gaseous media • Application Engine management • Function Registration of intake-manifold pressure or atmospheric pressure • Installation Air-intake tract • Sensing principle Micromechanics with piezoresistive sensor element (MEMS based) • Technical data – Supply S l voltage: lt 5V – Power consumption: 9 mA (typical) – Measuring range: < 400 kPa (absolute) – Response time: < 1 ms – Temperature range: -40°... +130°C M.S Ramaiah School of Advanced Studies - Bangalore 21 PEMP AEL2501 Acclerometers • Piezoelectric accelerometers are generally used as knock sensors. • A piezoelectric accelerometer is a seismic mass accelerometer using a piezoelectric crystal to convert the force on the mass due to acceleration into an electrical output signal. signal The piezoelectric crystal acts not only as a transducer but also as the suspension spring for the mass. • When used for knock detection, they also pick up other vibrations, these are kept at minimum by looking for a ‘knock’ a few degrees before and after the TDC. M.S Ramaiah School of Advanced Studies - Bangalore 22 11 PEMP AEL2501 • The signals from this type of sensors are detected by charge amplifiers. • The sensitivity of a vehicle knock sensor is about 20mV/g ( g=9.81 m/s2). • MEMS accelerometers are replacing conventional accelerometers for – – Knock sensing – Crash sensing – INS, etc M.S Ramaiah School of Advanced Studies - Bangalore 23 PEMP AEL2501 Knock sensor • Application Engine management • Function Registration g of structure-borne vibrations (knocking). Knocking combustion can damage the engine. The data from the knock sensor enables counter-measures to be undertaken. • Installation Engine block • Sensing principle Piezo-electrical • Technical data – Sensitivity at 5 kHz: 30 ± 6 mV/g – Linearity at 5-kHz value: ± 10 % – Frequency range: 3 kHz ...22 kHz – Temperature range: -40°...+150°C M.S Ramaiah School of Advanced Studies - Bangalore 24 12 PEMP Acceleration sensor AEL2501 • Application – ESP® – ABS – Safety (airbag systems) • Function Registration of accelerations in the X, Y and Z axes • Installation – Integration into circuit board (SMD) – Remote sensor • Sensing principle Surface mechanics (capacitive) • Technical data Measuring range (airbag) – – – – SMD element: 2 g...250 g Peripheral sensor: 50 g...250 g Sensor output: analog or digital Temperature range: -40°C...+120°C M.S Ramaiah School of Advanced Studies - Bangalore 25 PEMP Yaw-rate sensor AEL2501 • Application ESP® • Function Registration of the rotational movement of the vehicle around its vertical axis • Installation Passenger compartment • Sensing principle Micromechanics, CAN interface • Technical data – – – – – – Yaw-rate sensor measuring range: ±100°/s Acceleration sensor measuring range: ± 1.8 g Initialization time: <= 1.0 s Temperature range: -40°C...+85°C Supply voltage: 8.2 8 2 V...16 V 16 V Nominal voltage: 12 V M.S Ramaiah School of Advanced Studies - Bangalore 26 13 PEMP AEL2501 Air Flow Sensor • Air flow Sensor is another example of variable resistance sensor. • When air flows in to the sensor, exerts a force on the flap which is counteracted by a calibrated spring spring. This ensures that movement of the flap is proportional to the volume of air passing through the sensor. M.S Ramaiah School of Advanced Studies - Bangalore 27 PEMP AEL2501 • A slider potentiometer is connected to the flap shaft. • The resistive material used for the track is a ceramic metal mixture which is burnt into a ceramic plate at a very high temperature. • The potentiometer is calibrated such that the output voltage is proportional to the quantity of induced air. M.S Ramaiah School of Advanced Studies - Bangalore 28 14 PEMP AEL2501 Hot wire air flow sensor • This measures air mass flow. flow • The basic principle is that as air passes over a hot wire it tries to cool the wire down. A circuit is created that tends to increase the current through the wire. wire This current will be proportional to the air flow. • The hot-wire: – – – – – – Material - Platinum Few mm long Dia – about 70 microns. Time constant – very short (Small size) Current range – 0.5 to 1.2 A Dirt problem – Burn-off cycle at power-on or power-off. M.S Ramaiah School of Advanced Studies - Bangalore 29 PEMP AEL2501 By-pass hot wire air flow meter M.S Ramaiah School of Advanced Studies - Bangalore 30 15 PEMP AEL2501 Oxygen Sensor • The oxygen sensor provides a closed loop feedback for the engine management system to control the air fuel ratio. ratio • The amount of oxygen sensed is directly related to the mixture strength or air-fuel ratio. • Normalized air-fuel ratio(λ) = Current air- OBD II Requirement Sensor – 1 – Air/Fuel Ratio Sensor – 2 – Catalytic Converter Efficiency fuel ratio / Stoichiometric air-fuel ratio • The air-fuel air fuel ratio 14.7:1 14 7:1 by mass is known as a Lambda ((λλ) value of one. one M.S Ramaiah School of Advanced Studies - Bangalore 31 PEMP AEL2501 • The sensor operates reliably above 3000C. • The EGO – Exhaust Gas Oxygen sensors are placed in the exhaust manifold ensure adequate heating. • In some cases, a heating element is used to bring the temperature to the working level quickly. • These heating element do not operate all the time. (>8500C – Damage) • These are called HEGO. HEGO M.S Ramaiah School of Advanced Studies - Bangalore 32 16 PEMP AEL2501 • The main active component in most of the sensors is Zirconium dioxide, dioxide ZrO2 • This ceramic material is housed in gas permeable electrodes of platinum. platinum • At temperatures above 3000C, the zirconium dioxide will conduct negative oxygen ions. ions • The sensor is designed to be responsive very close to a Lambda value of 1. • Greater quantity of oxygen ions will be present near one of the electrode which is exposed to reference atmospheric air. M.S Ramaiah School of Advanced Studies - Bangalore 33 PEMP AEL2501 • Through electrolytic action these ions permeate the electrode and migrate through the electrolyte. This builds up the charge charge. • The magnitude of the charge is dependent on the oxygen % in the exhaust. • A voltage of 400mV is the normal value at lambda value of one one. • Most lambda sensors will cycle from rich to lean in about 50 to 100 milliseconds, and from lean to rich in 75 to 150 milliseconds. This is referred to as the "transition" time. If the O2 sensor is taking significantly longer to reverse readings, this too is an indication that it is getting sluggish and may need to be replaced. M.S Ramaiah School of Advanced Studies - Bangalore 34 17 PEMP AEL2501 Actuators • ‘Actuator’ is a general term to describe a control mechanism. • An actuator is part of an open open--loop or closed closed--loop control system which connects the electronic unit with the process. • The actuator consists of a transformer and a final-control element. • Each positioning signals are converted to mechanical output. M.S Ramaiah School of Advanced Studies - Bangalore 35 PEMP AEL2501 • A wide variety of actuators are used in control loops in an automobile • Some of the actuators are: – – – – Solenoids DC Motors Stepper motors Piezo Actuators and so on.. M.S Ramaiah School of Advanced Studies - Bangalore 36 18 PEMP AEL2501 Solenoid Actuators • A solenoid is defined as a coil of wire commonly in the form of a long cylinder that when carrying a current resembles a bar magnet so that a moveable core (armature) is drawn into (pulled (pulled--in) the coil when a currentt flows. flows fl • A more simple definition is that a solenoid is a coil and a moveable iron core used to convert electrical energy into mechanical energy. • Normally, the movement of the core compresses a spring. • On power-off, the armature returns back to its normal position. ii • The stroke of the armature varies from fraction of a mm to several mm depending on application. • There are two main categories of solenoids: – Rotary – rotary motion of the armature – Linear – linear motion of the armature M.S Ramaiah School of Advanced Studies - Bangalore 37 PEMP AEL2501 • Important considerations when designing a solenoid for an application: – – – – – – – – – – Stroke Force or Torque Voltage Current / Power Duty Cycle Temperature p Operating Time / Speed Environmental AC / DC Life M.S Ramaiah School of Advanced Studies - Bangalore 38 19 PEMP AEL2501 • One of the examples of solenoid actuator is the one used in Fuel injector. injector • A typical fuel injector solenoid has the follo ing: following: – Stroke: 0.1mm – Open period range: 1.5 to 10.0 ms. – Coil resistance : 16 Ω • Time taken by an injector to open and close is critical in fuel injection. • The induction of the coil pplays y an important role in the reaction time for the solenoid. (Higher inductance -> longer reaction time, ballast resistors) • Another application of solenoid actuator is for door locks. locks M.S Ramaiah School of Advanced Studies - Bangalore 39 PEMP AEL2501 Relays Electromagnetic switches M.S Ramaiah School of Advanced Studies - Bangalore 40 20 PEMP AEL2501 DC Motors • Permanent magnet motors are commonly used in automobiles as they are versatile. – The rotary speed (RPM) of the motor which is usually high is suitably i bl modified difi d through h h gearing i down d (i (increase in i torque)) or other mechanisms to get the desired rotary or linear motion. • For applications such as power electric steering, the options available are : – Brushless DC (BLDC) – Switched-reluctance motors (SRM) – The BLDC motor has permanent magnets that are susceptible to high temperature complications (automotive temperatures -40 to 125°C.) M.S Ramaiah School of Advanced Studies - Bangalore 41 PEMP AEL2501 • Typical Specifications of a DC Motor: – Voltage: 12V DC – No load speed: 9000r/min± 10% – No load current: ≤ 4A – Load: 7650r/min± 10%, 0.226Nm, ≤ 19A – Rotation direction: clockwise M.S Ramaiah School of Advanced Studies - Bangalore 42 21 PEMP AEL2501 Some of the automotive applications: – – – – – – Windscreen and head light washers & wipers. Power windows and mirrors. Fuel pumps Head light lifts. Electronic Parking Brake (EPB) Ventilation fans and so on.. • One of the draw backs of a DC motor is non-availability of direct feedback. feedback If required, one has to use variable resistor i sensor to get the h necessary feedback. f db k M.S Ramaiah School of Advanced Studies - Bangalore 43 PEMP AEL2501 • Ex: M.S Ramaiah School of Advanced Studies - Bangalore 44 22 PEMP AEL2501 Windows Motors Cable Window Lift Systems M.S Ramaiah School of Advanced Studies - Bangalore 45 PEMP AEL2501 Actuators for climate control Systems EPB Actuator Actuators for Locking Systems M.S Ramaiah School of Advanced Studies - Bangalore 46 23 PEMP AEL2501 Stepper Motors • Stepping motors: – Permanent magnet Type • Permanent magnet motors usually ll have h two t independent windings, with or without center taps. Center-tapped windings are used in unipolar permanent magnet motors. – Variable reluctance Type • Variable reluctance motors usually have three (sometimes four or five) windings, with a common return. M.S Ramaiah School of Advanced Studies - Bangalore 47 PEMP • Angular resolution: AEL2501 – The coarsest motors typically turn 90 degrees per step – High resolution permanent magnet motors are commonly able to handle 1.8 or even 0.72 degrees per step. – With an appropriate i t controller, t ll mostt permanentt magnet and hybrid motors can be run in halfsteps, and some controllers can handle smaller fractional steps or microsteps. • For both permanent magnet and variable reluctance stepping motors, if just one winding of the motor is energized, the rotor (under no load) will snap to a fixed angle and then hold that angle until the torque exceeds the holding torque of the motor, at which point, the rotor will turn, trying to hold at each successive equilibrium point. • They do not have high starting torque torque. M.S Ramaiah School of Advanced Studies - Bangalore 48 24 PEMP AEL2501 • Applications: – – – – Idle speed air by-pass Electronic Throttle control Speedometer display drives Adaptive Front-lighting (AFS) system, etc. Adaptive Front-lighting System Digital Instrument Cluster M.S Ramaiah School of Advanced Studies - Bangalore 49 PEMP AEL2501 Piezo Actuators • A piezo actuator enables response times of just a few Tenth of a millisecond. • It consists of many crystal layers that expand by a few hundredths of millimeters when voltage is applied. • One of the automotive applications of the Piezo actuators is in Diesel Unit Injection Systems. • Example: – Stacked actuator • • • • Motion up to 100 µm Maximum load 3500 N Very high stiffness up to 200 N/µm Voltage -10...150V (multi-layer) M.S Ramaiah School of Advanced Studies - Bangalore 50 25 PEMP AEL2501 A Case Study: HONDA City Engine Throttle Body Master Cylinder Battery Engine (Transverse mounted) Air Filter Alternator M.S Ramaiah School of Advanced Studies - Bangalore 51 PEMP AEL2501 HONDA City Engine sensors IAT Sensor MAP Sensor • Manifold Air Temperature p sensor – measures the temperature of incoming air. • Manifold Absolute Pressure sensor – measures the –ve pressure in the inlet manifold. M.S Ramaiah School of Advanced Studies - Bangalore 52 26 PEMP AEL2501 HONDA City Engine sensors Purge Control Solenoid Throttle Body Wiring Harness TPS ISC Solenoid • Purge Control Valve – part of the evaporative emission control system. • TPS- Throttle Position Sensor measures the throttle valve opening. • ISC Solenoid – Idlingg speed p control solenoid controls the flow of air during idling of engine to control the speed of engine within the specified range. M.S Ramaiah School of Advanced Studies - Bangalore 53 PEMP AEL2501 HONDA City Engine sensors MAP Sensor Ignition Coils (on plug) Starter Motor Fuel Injector M.S Ramaiah School of Advanced Studies - Bangalore 54 27 PEMP AEL2501 HONDA City Engine sensors • One of the important sensors mounted on engine. • Senses the coolant temperature surrounding the engine cylinder in the engine block. M.S Ramaiah School of Advanced Studies - Bangalore 55 PEMP AEL2501 HONDA City Engine sensors Master Cylinder A/C system Pressure Sensor Brake Fluid Level sensor M.S Ramaiah School of Advanced Studies - Bangalore 56 28 PEMP AEL2501 Completely assembled Porsche engine M.S Ramaiah School of Advanced Studies - Bangalore 57 PEMP AEL2501 Cam shaft position sensor CAM Shaft Cam shaft sensor mounting • The cam shaft sensor is mounted on the engine near the cam shaft. • It is a Hall effect transducer which generates an electrical signal that is proportional to the rotation of the cam shaft. M.S Ramaiah School of Advanced Studies - Bangalore 58 29 PEMP AEL2501 Knock Sensor Knock sensor mounting • The knock sensor is mounted on the engine block. • It is essentially an accelerometer which generates an electrical signal that is proportional to the vibration of the cylinder block. M.S Ramaiah School of Advanced Studies - Bangalore 59 PEMP AEL2501 Crank shaft position / Speed sensor Fly wheel • Crankshaft position/speed sensor is mounted near the flywheel. • The flywheel will have projections that generate the pulses. • These pulses are handled by the ECU to generate the necessary information. M.S Ramaiah School of Advanced Studies - Bangalore 60 30 PEMP AEL2501 Oxygen Sensors • The oxygen sensors are also known as the Lambda Sensors. Sensors • They Th are located l t d in i the th exhaust gases leaving the cylinder. • They measure the amount of oxygen present in the exhaust p gases. • This information is used to control the emission M.S Ramaiah School of Advanced Studies - Bangalore 61 PEMP AEL2501 Summary • Various types of automotive sensors and actuators have been discussed in terms of working ki principles, i i l applications li ti in i automotive electronic systems. M.S Ramaiah School of Advanced Studies - Bangalore 62 31