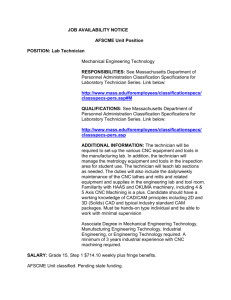

Design and Fabrication 2202

advertisement