Tin-Plated Air Coil

advertisement

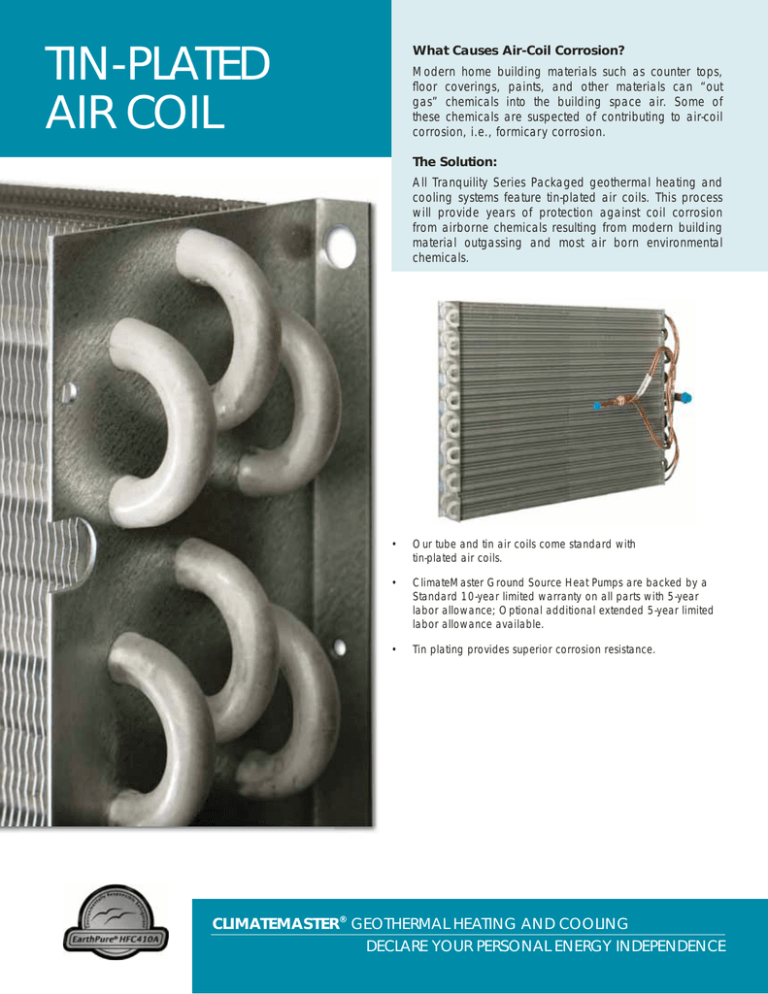

TIN-PLATED AIR COIL What Causes Air-Coil Corrosion? Modern home building materials such as counter tops, floor coverings, paints, and other materials can “out gas” chemicals into the building space air. Some of these chemicals are suspected of contributing to air-coil corrosion, i.e., formicary corrosion. The Solution: All Tranquility Series Packaged geothermal heating and cooling systems feature tin-plated air coils. This process will provide years of protection against coil corrosion from airborne chemicals resulting from modern building material outgassing and most air born environmental chemicals. • Our tube and tin air coils come standard with tin-plated air coils. • ClimateMaster Ground Source Heat Pumps are backed by a Standard 10-year limited warranty on all parts with 5-year labor allowance; Optional additional extended 5-year limited labor allowance available. • Tin plating provides superior corrosion resistance. CLIMATEMASTER® GEOTHERMAL HEATING AND COOLING DECLARE YOUR PERSONAL ENERGY INDEPENDENCE Tin-Plated Air Coil What is Tin Plating or Electroplating? The tin-plating process is used extensively to protect both ferrous and nonferrous surfaces. Tin is a useful metal for the food processing industry since it is nontoxic, ductile and corrosion resistant. The excellent ductility of tin allows a tin coated base metal sheet to be formed into a variety of shapes without damage to the surface tin layer. It provides sacrificial protection for copper, nickel and other non-ferrous metals. Electroplating is a plating process that uses electrical current to reduce cations of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal. Electroplating is primarily used for depositing a layer of material to bestow a desired property (e.g., abrasion and wear resistance, corrosion protection, lubricity, aesthetic qualities, etc.) to a surface that otherwise lacks that property. The process used in electroplating is called electrodeposition. It is analogous to a galvanic cell acting in reverse. The part to be plated is the cathode of the circuit. In one technique, the anode is made of the metal to be plated on the part. Both components are immersed in a solution called an electrolyte containing one or more dissolved metal salts as well as other ions that permit the flow of electricity. A power supply supplies a direct current to the anode, oxidizing the metal atoms that comprise it and allowing them to dissolve in the solution. At the cathode, the dissolved metal ions in the electrolyte solution are reduced at the interface between the solution and the cathode, such that they “plate out” onto the cathode. The rate at which the anode is dissolved is equal to the rate at which the cathode is plated, vis-a-vis the current flowing through the circuit. In this manner, the ions in the electrolyte bath are continuously replenished by the anode. The result is a consistent and uniform tin plating across the copper hairpin. 7300 S.W. 44th Street Oklahoma City, OK 73179 Phone: 405-745-6000 Fax: 405-745-6058 climatemaster.com cmdealernet.com geoexchange.org ClimateMaster works continually to improve its products. As a result, the design and specifications of each product at the time for order may be changed without notice and may not be as described herein. For specific information on the current design and specifications go to cmdealernet.com. Statements and other information contained herein are not express warranties and do not form the basis of any bargain between the parties, but are merely ClimateMaster’s opinion or commendation of its products. RP874 © 2010 ClimateMaster, Inc. Rev.: 9/28/16