MSI+ (e) .indd

advertisement

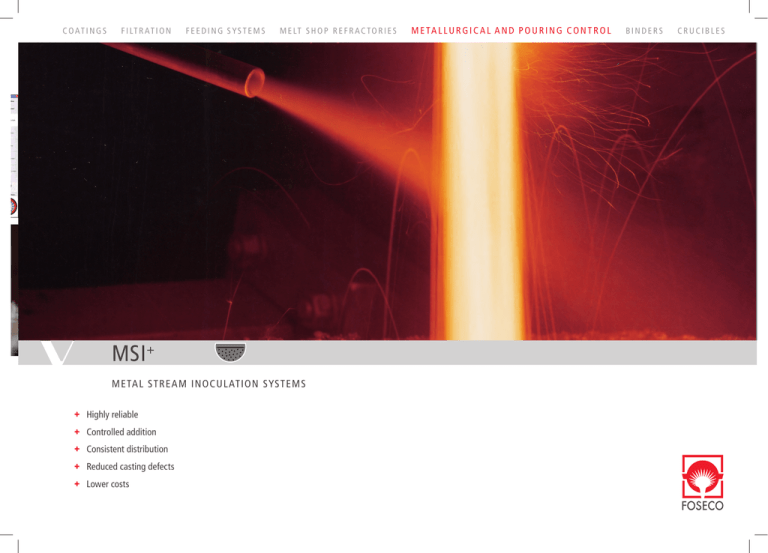

C O A T I N G S F I LT R A T I O N F E E D I N G S Y S T E M S M E LT S H O P R E F R A C T O R I E S M E T A L L U R G I C A L A N D P O U R I N G C O N T R O L B I N D E R S C R U C I B L E S MSI+ M ETAL STREAM I N O C ULAT ION S YS T E MS ++ Highly reliable ++ Controlled addition ++ Consistent distribution ++ Reduced casting defects ++ Lower costs MSI+ MSI In-Stream Inoculant Dispensing Systems for Fixed-Station Pouring MSI In-Stream Inoculation Systems MSI represents a range of in-stream inoculant dispensing systems from Foseco. MSI systems are designed specifically for use with Foseco’s range of INOCULIN* alloys. MSI systems can be customised to meet the unique needs of foundries and can be integrated with most automated pouring systems to achieve the highest level of metallurgical process control across a full spectrum of iron grades. Over the past 25 years, having sold over 600 MSI systems worldwide, Foseco has been a leading innovator in the field of in-stream inoculation dispensing technology. It has filed a variety of in-stream inoculation patents and contributed significantly to the application of related technology in the industry. Importance of in-stream inoculation The influence of ferro-silicon alloy additions changes over time based a phenomenon commonly called “fade”. The rate of fade depends on the composition of the inoculating alloy, metal casting process temperatures, and the chemical composition of base iron. In order to achieve consistent solidification and physical properties of iron, inoculating alloys are ideally added to the melt immediately before solidification. The efficiency of an inoculant is highest when it is added to the pouring stream as it enters the mould cavity. 2 The economical and effective application of inoculating alloys places stringent demands on both inoculation alloy and dispensing systems. Consistent dissolution and nucleation in the melt requires inoculating alloys with relatively low melting points and a consistent grain size distribution. The composition of inoculating alloys should be closely aligned with the specific grade of iron to which it is applied. MSI systems are applicable to flake graphite, spheroidal graphite and compacted graphite iron grades. MSI+ 900 MSI+ 900 inoculant dispensing systems incorporate basic ferro-alloy dispensing features that can be successfully applied in the majority in-stream applications. The system is comprised of: ++ control panel with power supply ++ communications interface ++ gravity feed “hot-box” dosing unit ++ inoculating pipe ++ cable package for compressed air and electrical supplies. MSI+ DC Dynamic Inoculant Dispensing System The most recent innovation in the area of in-stream inoculation is a concept called “Dynamic Inoculation Control”. Advanced MSI+ DC systems create value for foundries by delivering the right about of inoculating alloy, in the right place, at the right time, and at the lowest possible overall cost. MSI+ DC (“Dynamic Control”) dispensing systems incorporate novel control features designed for the most demanding in-stream applications. The base model system is comprised of: ++ control panel with power supply ++ communications interface ++ vertical screw feeding “hot-box” dosing unit ++ inoculating pipe ++ cable package. Optional features include: ++ INOCHECK visual sensing control system – assures that INOCULIN alloy is being dispensed into the metal stream at the desired time, location and rate ++ INOCELL dynamic weight control system – measures a predetermined mass of INOCULIN alloy to assure accuracy in alloy dispensing weight ++ ITACA thermal analysis system – assures that the desired nucleation state of iron is achieved and maintained ++ MSI+ DC can be controlled using an electrical signal from the stopper control system or through the use of an optical camera sensing system. Assuring the accuracy of inoculating alloy dispensing The INOCHECK visual sensing system continuously monitors and controls the position and dispensing rate of INOCULIN relative to the metal stream as it enters the mould. INOCHECK analyses visual images acquired from a camera sensor at an imaginary vertical plane formed by the iron stream and the end of the dispensing tube. At the instant that the camera sensor is activated by the presence of the iron stream during the pouring cycle, INOCULIN is dispensed and the system detects and quantifies the presence of grains of inoculating alloys visible in the iron stream. The system measures the concentration of inoculating alloys in the metal stream and immediately alerts to any deviation from predefined norms. To ensure perfect traceability, the INOCHECK system stores images of each pouring operation. The data can be easily sorted by category and displayed on the control panel or remote monitor. In the event of virtually any casting problem, INOCHECK characterises the relative quality of inoculation for each mould poured. The INOCHECK system thus enables: ++ validation that each mold has been sufficiently inoculated ++ assurance by the operator that inoculating alloys have been synchronised with the metal stream ++ assurance by the operator that the inoculating alloys are directed at the metal stream using the alignment feature MSI+ DC control unit MSI+ DC dosing equipment (Hot Box) Internal view of the dosing equipment INOCHECK 3 MSI+ MSI In-Stream Inoculant Dispensing Systems for Fixed-Station Pouring Controlling the weight of inoculating alloys An optional dynamic load cell feature called INOCELL assures a high level accuracy and control of the INOCULIN dispensing rate. Stabilising the nucleation state of iron via thermal analysis Key foundry process variables like inoculation rate, holding time, and process temperatures strongly influence the nucleation state of iron. Consequently, constant inoculation rates – normally seen as a controllable process parameter – can result in variability in the nucleation state of iron and thus iron metallurgy and physical properties (free-carbide, graphite-shape, shrinkage tendency, nodule count, nodularity, ferrite/pearlite ratio). MSI+ DC can be equipped with an optional, fully integrated, thermal analysis system, called ITACATM. Foundries can leverage the advantages of an integrated ITACATM system to control the influence of in-stream inoculation. This is accomplished by periodically sampling the melt to measure its real-time carbon equivalent value (CEV) and nucleation state which is automatically derived from the cooling curves and first derivative analyses. ITACATM then calculates the appropriate addition rate for inoculating alloys allowing the operator to make necessary adjustments using the MSI+ DC control panel thus minimising variation in inoculation state and the consumption rate and cost of INOCULIN alloys. ITACATM thermal analysis 04/2015 · e ITACATM cup testing *FOSECO, the Logo and INOCULIN are trade marks of the Vesuvius Group, registered in certain countries, used under licence. ITACATM is a trademark of ProService. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system of any nature or transmitted in any form or by any means, including photocopying and recording, without the written permission of the copyright holder or as expressly permitted by law. Applications for permission shall be made to the publisher at the address mentioned. Warning: The doing of an unauthorised act in relation to a copyright work may result in both a civil claim for damages and criminal prosecution. All statement, information and data contained herein are published as a guide and although believed to be accurate and reliable (having regard to the manufacturer’s practical experience) neither the manufacturer, licensor, seller nor publisher represents nor warrants, expressly or impliedly: (1) their accuracy/reliability, (2) that the use of the product(s) will not infringe third party rights, (3) that no further safety measures are required to meet local legislation. The seller is not authorised to make representations nor contract on behalf of the manufacturer/licensor. All sales by the manufacturer/seller are based on their respective conditions of sale available on request. © Foseco International Limited 04/15. COMMITTED TO FOUNDRIES Foseco International Limited Drayton Manor Business Park, Tamworth, Staffordshire, England B78 3TL Phone: +44 (0)1827 262021 Fax: +44 (0)1827 283725 www.Foseco.com Please contact your local Foseco team