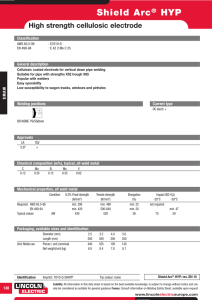

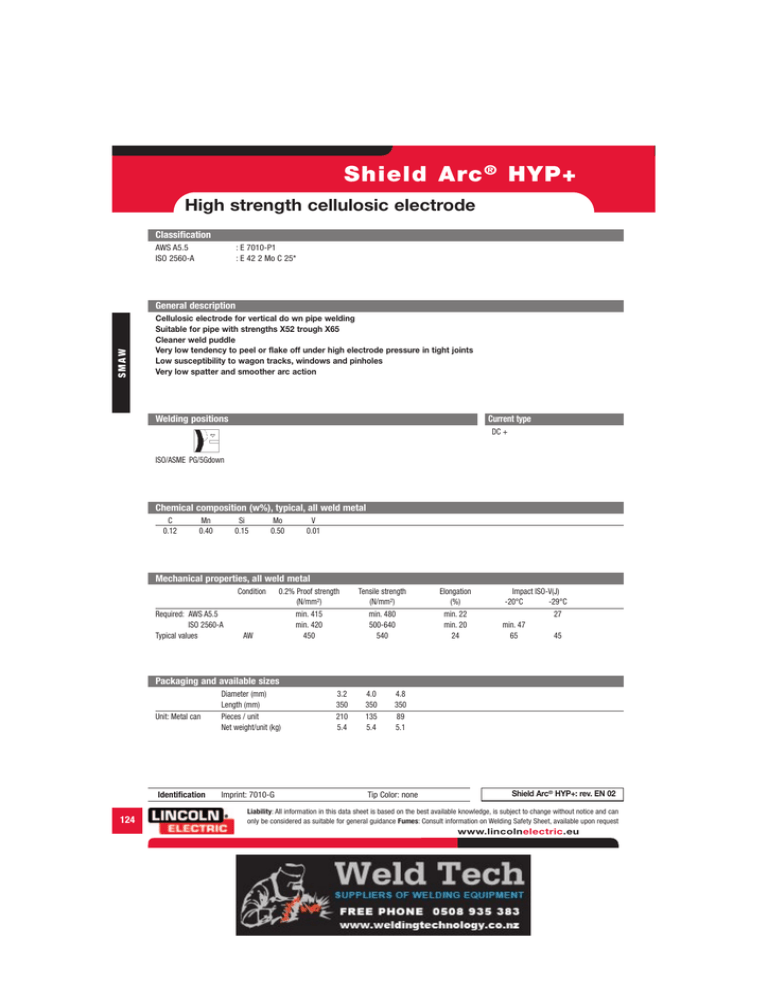

Shield Arc® HYP+

advertisement

Shield Arc ® HYP+ High strength cellulosic electrode Classification AWS A5.5 ISO 2560-A : E 7010-P1 : E 42 2 Mo C 25* S M AW General description Cellulosic electrode for vertical do wn pipe welding Suitable for pipe with strengths X52 trough X65 Cleaner weld puddle Very low tendency to peel or flake off under high electrode pressure in tight joints Low susceptibility to wagon tracks, windows and pinholes Very low spatter and smoother arc action Welding positions Current type DC + ISO/ASME PG/5Gdown Chemical composition (w%), typical, all weld metal C 0.12 Mn 0.40 Si 0.15 Mo 0.50 V 0.01 Mechanical properties, all weld metal Condition Required: AWS A5.5 ISO 2560-A Typical values AW 0.2% Proof strength (N/mm2) min. 415 min. 420 450 Tensile strength (N/mm2) min. 480 500-640 540 Elongation (%) min. 22 min. 20 24 Impact ISO-V(J) -20°C -29°C 27 min. 47 65 45 Packaging and available sizes Unit: Metal can Identification 124 Diameter (mm) Length (mm) Pieces / unit Net weight/unit (kg) Imprint: 7010-G 3.2 350 210 5.4 4.0 350 135 5.4 4.8 350 89 5.1 Tip Color: none Shield Arc® HYP+: rev. EN 02 Liability: All information in this data sheet is based on the best available knowledge, is subject to change without notice and can only be considered as suitable for general guidance Fumes: Consult information on Welding Safety Sheet, available upon request www.lincolnelectric.eu Shield Arc ® HYP+ Materials to be welded Steel grades/Code Pipe material EN 10208-2 EN 10216-1 / 10217-1 API 5LX Gaz de France Type S M AW L360, L415, L445 P 355 X52, X56, X60, X65 X52, X63 Calculation data Sizes Diam. x length (mm) Current range A) Current type 3.2x350 4.0x350 4.8x350 75-130 90-185 140-185 DC+ DC+ DC+ Arc time Energy Dep.rate - per electrode at max. current (s)* E(kJ) H(kg/h) Weight/ 1000 pcs. (kg) Electrodes/ kg weldmetal B kg Electrodes/ kg weldmetal 1/N 25.8 39.5 57.1 Welding parameters, optimum fill passes Welding positions Diameter (mm) 3.2 4.0 4.8 PG/5G down 110A 150A 165A Remarks/ Application advice Preheating pipe material from L380 to L450 (X56 to X65) required (acc. EN 1011-1). Pipeclamps to be removed after finishing root pass, start welding hot pass (within 5 min) after root pass Use electrodes directly from metal cans Use Fleetweld 5P+ for lower hardness in the root pass 125