From Proven Acceptable Ranges to Design Space

advertisement

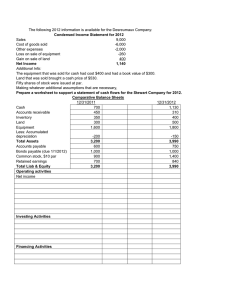

IVTJVT1107.qxd 10/8/07 3:27 PM Page 50 From Proven Acceptable Ranges to Design Space BY TIM FIELDS ❖ INTRODUCTION International Conference on Harmonization (ICH) Q8, Pharmaceutical Development1 was finalized in November 2005 and introduced the concept of “Design Space.” The idea of defining criteria within which one must control a process to ensure that a quality product is produced is not a new concept. The late Ken Chapman proposed the precursor to the design space concept two decades earlier when he introduced the idea of Proven Acceptable Ranges or the PAR Approach2 to process validation. The PAR Approach and Design Space are based on the same principle, that is, quality must be built into the product, it cannot be tested in. Design Space and the PAR Approach also emphasize the importance of the product lifecycle and the process and product knowledge gained through research and process development. BACKGROUND The 1987 FDA, “Guideline on the General Principles of Process Validation”3 defines process validation as: “establishing documented evidence which provides a high degree of assurance that a specific process will consistently produce a product meeting its predetermined specifications and quality attributes.” The PAR Approach focuses on defining the critical process parameters and the ranges within which they must be controlled to ensure that the product meets it predetermined quality attributes. The Design Space, on the other hand, focuses on defining multiple critical elements of the process, including the critical process parameters, 50 Journal of Validation Technology which when properly controlled, will ensure that a product meeting its predetermined specifications and quality attributes is produced. Chapman proposed the PAR Approach while the FDA was in the process of drafting the guidelines on process validation. One concern about the early draft guide was the use of the terms “worst case” and “edge-of-failure.” At the time, worst case appeared to be an ambiguous term, which had multiple interpretations, including: stress testing, upper and lower PAR limits, upper and lower operating limits, upper and lower control limits, and edge-of-failure. The term edge-of-failure appeared to be a better understood term, meaning that exceeding the edge-of-failure would result in an adverse event. Although knowing the edge-of-failure for a process parameter may be useful in some cases, its relevance to process validation is questionable. Establishing the Proven Acceptable Range or PAR of a process is more relevant to process validation. The objective of the PAR Approach is to gather documented evidence (proven acceptable) that supported the upper and lower limits (range) within which a critical process parameter is to be controlled to ensure that the product meets its pre-defined specifications. The Design Space concept grew out of the ICH Q8 Guideline on Pharmaceutical Development, which focused on using good science and experience to design a quality product and manufacturing process that would consistently result in a quality product. The knowledge gained during process development is used to define the Design Space for the product. The Design Space can then be used to establish specifications for materials and to set process control limits. While the PAR Approach tends to be two-dimensional (i.e., critical process parameters and their effect on qual- IVTJVT1107.qxd 10/8/07 3:27 PM Page 51 Tim Fields Figure 1. The PAR and Design Space Approaches Compared Raw materials properties Environmental factors Processing conditions High Low Design Space PAR Approach ity attributes), Design Space, as the name implies, examines multiple aspects of the process (Figure 1). The PAR Approach examines the effects of altering one parameter at a time (e.g., adjust tablet hardness and look at the effect on friability or dissolution). Design Space relies on multi-variant Design of Experiments to look at a number of variables and their effect on the product. Chapman recognized that there were situations when more than one variable could affect an attribute or that multiple variables acting together could exacerbate the effect on a quality attribute. In his 1984 paper on the PAR Approach, Chapman indicated that notations should be made when such information was known. The PAR Approach involves the examination of data obtained during development, when possible, to support the critical process parameter ranges. Using lab scale experiments, if possible, or product knowledge, the probable adverse consequences of exceeding the established ranges are determined. Each critical step is evaluated to determine the effect that the potential critical process parameters have on the quality attributes. If the proven acceptable ranges are exceeded, one uses knowledge from the experimental studies to test for the occurrence of probable adverse consequence. For example, if the development data supported tablet compression settings of 8 to 12, and the probable adverse consequence of exceeding the range on the low end is poor friability, and exceeding the range on the upper end is poor dissolution profile, then when the range is exceeded, the friability or dissolution would be examined, respectively. If the probable adverse event did not occur, the range could be broadened based on this new Proven Acceptable Range. Design Space uses the knowledge gained during development and manufacturing experience to provide a scientific understanding of the interactions of the multiple variables that may be involved in a process including the process parameters, materials, equipment, and environmental conditions. N ove m b e r 2 0 0 7 • Vo l u m e 1 4 , N u m b e r 1 51 IVTJVT1107.qxd 10/8/07 3:27 PM Page 52 Tim Fields Today, science, technology, and knowledge allow for a more thorough understanding of the process and the variables that affect it than were available when Chapman proposed the PAR Approach. For example, using the PAR Approach, if one only examined the tablet machine compression settings to determine the effect on tablet hardness, then the impact of particle size might be overlooked. Design Space would include consideration of multiple variables on the process and the product. To ensure that a process remains in control, a pyramiding approach is often used to set normal operating parameter control limits within the PAR or Design Space limits. If the difference between the PAR for a process parameter and the normal operating range is wide, then the process is robust, because it allows for wide variation with no effect on the product quality. The PAR Approach and Design Space concept for process validation require knowledge to be captured and retained about the process and the effects that critical process variables have on the process. Both concepts are based on a product lifecycle starting with the process development and continuing until the process is retired. Both concepts advocate the use of small scale lab studies, when possible, to support the processing parameters and quality attributes. RELATIONSHIP WITH OTHER GUIDELINES The Design Space concept and The PAR Approach align well with and rely on compliance with ICH Q9, Quality Risk Management4, and the FDA Quality System Guidance Document5. Using the PAR Approach or the Design Space concepts are only part of process validation. To ensure that a process is validated also requires that a Quality System be in place. A good Quality System ensures appropriate controls over personnel, equipment, facilities, procedures, documentation, deviation investigations and corrections, and change control. Both the PAR Approach and Design Space also fit well with a Risk Based Approach to process validation by providing the documented evidence that supports riskbased decisions regarding the impact of process deviations. In addition to using the knowledge from the PAR 52 Journal of Validation Technology Approach or Design Space concept to support risk-based decisions, risk assessment tools and processes can also be used to identify the critical steps in a process, the critical process parameters, and the critical quality attributes of the product. Chapman recommended that in-process control data be recorded in addition to the critical operating parameters because such information could be used in making process-related decisions. In today's regulatory environment, such data can be used to implement Process Analytical Technology (PAT) or continuous process verification to monitor and control processes. In a similar manner, Design Space concepts lead to the identification of key control points (i.e., in-process controls) that can also be implemented using PAT or continuous process verification. The knowledge of the process and the affects of changes within the PAR and Design Space allow for variation within PAR or the Design Space, and therefore, should be documented and handled appropriately within the company without the need for initiating a regulatory post-approval change. LIFECYCLE APPROACH While both the PAR Approach and Design Space are useful methods for providing documented evidence that supports the critical process parameter ranges and control points, it is important to remember that process validation does not end there. Data must be collected to provide evidence that the process is reproducible and robust. Data must continually be reviewed for impact on PAR or the Design Space. As previously mentioned, process variability within the PAR or Design Space should not require regulatory review, however, when exceeding the PAR or Design Space, evidence of the effects on the validated process must be documented and the PAR or Design Space appropriately revised. CONCLUSION The PAR Approach can certainly be viewed as a precursor to Quality by Design and Design Space concepts. The PAR Approach is two-dimensional, while Design Space is multi-variant. The PAR Approach is somewhat IVTJVT1107.qxd 10/8/07 3:27 PM Page 53 Tim Fields retrospective in that it evaluates data to establish the Proven Acceptable Ranges, while Design Space is more prospective in using scientific knowledge to establish control parameters. There appears to be a greater need for the application of scientific knowledge involved in the use of Design Space than needed for the PAR Approach. Design Space is based on the plan or conception of the process, while the PAR Approach is based more on demonstrating the verified, established limits in a given process.The PAR Approach and Design Space are similar concepts focused on ensuring product quality is designed into the product using good science and product and process knowledge. Both concepts focus on a lifecycle approach to gain knowledge to improve drug product quality. The process and product knowledge gained from these two approaches provide for a better understanding of the impact of process variability on a product. With continuing increases in technology and efforts to find new, better, and cheaper ways of validating processes, it is likely that Design Space will eventually lay the foundation for a new approach much as Chapman's PAR Approach laid the foundation for Design Space. ❏ ABOUT THE AUTHOR Tim Fields is the President of Drumbeat Dimensions, Inc. (DBD), a professional compliance management company located in Mystic, CT, which provides products and services designed to help firms assess and enhance their regulatory compliance. Mr. Fields has over 22 years of experience in the pharmaceutical industry including 13 years with Pfizer where he was responsible for organizing and managing the corporate software quality assurance audit program. Tim is a member of the Editorial Advisory Board for the Journal of GXP Compliance as well as a member of the International Society of Pharmaceutical Engineers (ISPE), Parenteral Drug Association (PDA), and GAMP Americas Manufacturing Execution Systems (MES) Special Interest Group. He has published and lectured worldwide on computer-related system validation, electronic signatures and records, and document management. He can be reached by telephone at 860-572-7255, or by email at:Tim_Fields@drumkey.com REFERENCES 1. International Conference on Harmonization. “ICH Q8, Pharmaceutical Development,” ICH, November 2005. 2. Chapman, K.G., “The PAR Approach to Process Validation,” Pharmaceutical Technology, 8 (12), 22-36 (1984). 3. FDA, “Guideline on General Principles of Process Validation,” Final. May 1987. 4. International Conference on Harmonization, “ICH Q9, Quality Risk Management,” Federal Register 70 (151), 45722-45723 (August 8, 2005). 5. U.S. Food and Drug Administration, “Guidance for Industry; Quality Systems Approach to Pharmaceutical Current Good Article Acronym Listing Manufacturing Practice Regulations,” FDA, September 2006. 6. U.S. Food and Drug Administration, “Pharmaceutical cGMPs for the 21st Century - A Risk Based Approach,” FDA, August 2002. FDA Food and Drug Administration ICH International Conference on Harmonization PAR Proven Acceptable Range PAT Process Analytical Technology N ove m b e r 2 0 0 7 • Vo l u m e 1 4 , N u m b e r 1 53