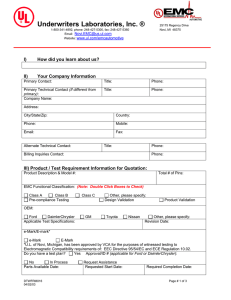

EMC Performance Requirements --

advertisement