FIELD WIRING DIGRAM ATLAS RETAIL

advertisement

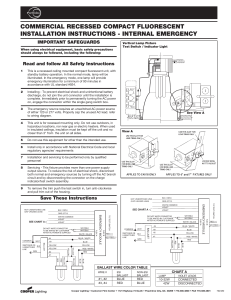

Safety Procedures WARNING Dangerous environment. Highly flammable/explosive fuels and high voltage are present. Failure to observe all safety precautions could result in serious injury or death. Observe all safety precautions as outlined in Gasboy manuals. Installation Procedures 1. Install a single EMERGENCY POWER CUTOFF control to remove AC power from site dispensing equipment. (The control is an additional safety feature, and not a substitute for NEC/NFPA30 circuit breaker requirements). Label the EMERGENCY POWER CUTOFF switch and instruct owner to keep area clear of obstacles. 2. Connect an insulated grounding conductor from the dispenser power panel to the site grounding electrode (size per NEC). 3. Install power breakers to each circuit leading to the dispensing unit and STP. It must be capable of simultaneously disconnecting hot and neutral conductors. Note: In Canada, switching neutral is contrary to the Canadian Electrical Code, reference part 1, rule 14-014. 4. Only field wiring connections are shown in the junction boxes. Cap all unused wires. Local and National Electrical Codes may apply. 5. Install conduit per NEC for hazardous locations. Potting is required for conduit that passes through any portion of a hazardous vapor area to ensure vapor barrier integrity. Wires - All wires are 14AWG (copper stranded) unless otherwise noted. Dispenser ground wire is 12AWG (copper stranded). Power loading and distance run may require larger wire size. Wire all circuits NEC Class 1, except wiring to speaker (intercom) and call button which must be NEC Class 2. Gasboy two-wire is NEC Class 1 and may share the main power conduit. 9. 10. 7. 8. 2-Wire Communication Wiring: For installations with 'new' wiring, use unshielded twisted pair (UTP) data wires. Wiring Spec: 10-12 twists per foot, 18AWG up to 1000 foot runs (2000 ft. total) or 14AWG up to 2600 foot runs (5200 ft. total) unshielded, 300V minimum, stranded annealed copper tinned wire, PVC insulation of type TFFN, THHN or MTW, UL approved gasoline and oil resistant. Reference C&M Corporation Part #27525 (18AWG) or equivalent. See site preparation manual requirements where 14 AWG may be required. Consult manufacturer specifications for wire nuts to determine maximum number of wires that may be used per nut. STP isolation relay boxes are required by NEC 514-6 to: a. Allow service of one unit safely without removing power from all dispensing equipment. b. Prevent damage to equipment from cross-phasing. Damage caused by cross-phasing is not covered by warranty. (Use local supplier for Isolation Relay Boxes). To avoid damage to the CPU PC board, all unused wires must be individually capped. Before applying power, you must verify that the RESET COMPLETE, FAST FLOW, SUBM. STARTER DRIVE wires are not shorted to conduit or chassis. 11. SUBM. STARTER DRIVE line can supply 300 mA AC maximum to control submersible starter relays. This line must not be directly connected to a submersible pump. 12. External submersible relays are required unless the remote dispenser is equipped with the submersible drive relay option. The submersible drive relay option provides a SUBM PUMP DRIVE line (MOTOR 1 HOT) which can directly drive a submersible pump up to 3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC. The 14 gauge MOTOR 1 or 2 FEED and MOTOR 1 or 2 HOT wires are always present. Verify that the submersible drive relay option is installed prior to wiring. The power supplied to the MOTOR 1 or 2 FEED must be able to handle the load of the submersible pump. 13. RESET COMPLETE (switch detect) line can supply 170 mA AC maximum for connecting to fuel management system circuitry and in applications where control of a remote slow flow valve (satellite) is required. 14. FAST FLOW line can supply 170 mA AC maximum is provided to allow for control of a satellite along with remote control or monitoring of the fast flow valve found in the pump. 15. If the AUTH (CONTROL/PUMP MOTOR FEED) line is controlled by a fuel management system using solid state relays, a resistor assembly must be installed between the Control Feed line and Feed Neutral to prevent false triggering of the authorization input. The resistor assembly is 8.2K OHM, 10 Watt (P/N C05818) for 115/230 VAC domestic and 30K OHM, 10 Watt (P/N C06683) for 230 VAC international wiring. 16. 17. 6. Do not provide service loops or leave excess wire in electronics cabinet. Cut all wire lengths to size sufficient to reach termination without stress or excess. Dress all wires neatly along surfaces so as not to obstruct access to terminations and devices. When used with an aboveground tank, the valve mounted at the tank MUST NOT be connected to the RESET COMPLETE or SUBM STARTER DRIVE lines. If the optional internal relay kit is installed AND the valve's current draw will not exceed 1 Amp, the valve can be connected to the SUBM PUMP DRIVE line. Otherwise, it should be driven from the external submersible starter relay. In all cases, the tank valve must operate at the same voltage as the submersible pump. When multiple dispensers are used to control a common submersible starter relay or pump, and the Atlas unit is controlled (authorized) through the AUTH (Control/Motor Feed) line (as in the case of some fuel management systems), it is important that the lines from the Atlas unit to the submersible equipment be isolated from each other. This can be accomplished by running the submersible control lines through a secondary set of relay contacts in the fuel management system. If a secondary set of contacts is not available, external control relays must be used between the Atlas unit and the submersible starter relay or pump. Another option is to provide a separate submersible starter relay for each hose outlet. In no case can the submersible drive lines from the Atlas unit be tied together. 18. When using remote dispensers and submersible starter relays are always recommended when a submersible pump is used. However, the control circuit is capable of directly driving a submersible pump up to 1 HP at 115/230 VAC. Any pump over these ratings will require a submersible starter relay. 19. If combining a remote dispenser with a fuel management system, the maximum HP limitation for directly driving a remote dispenser without the use of an additional relay of submersible starter must be the lower of the two components. 20. Internal wiring that is not field terminated may be white in color. 21. Wires labeled with two colors signify that the first color is the color of the wire and the second is that of the stripe. For example, BLU/WHT would indicate a blue wire with a white stripe. 22. DC conduit is used only in Pulse-out units. Electrical Rating Control Valves 0.2 AMP @120 VAC 0.1 AMP @ 240 VAC Electric Reset Motors 2.2 AMP @120 VAC 1.1 AMP @ 240 VAC Lights 1.0 AMP @ 120 VAC 50/60 Hz. 0.5 AMP @ 240 VAC 50/60 Hz. Gasboy recommends the use of one 15 AMP breaker per dispenser Gasboy requires valance lights be placed on a separate 15 AMP breaker. Important Note: Sharing conduit to the dispensers with other non-Gasboy devices is contrary to the installation and site preparation manuals and may void warranty. Active STP Connections The Atlas Dispenser STP1 STP2 X One-Grade .............................. X X Two-Grade ............................ Reference Manuals MDE-4333 Atlas Site Preparation Manual MDE-4331 Atlas Installation Manual Contents Models Description Sheet Cover Sheet (Safety, notes and specifications) Atlas Retail Dispenser with Electronic Display Pulse-out Field Wiring Diagram. Atlas Commercial Dispenser with Electronic Display Field Wiring Diagram. 8852KX, 8853KX, 8852KXTW1, 8853KXTW1, 8852KXTW2, 8853KXTW2 9852KX, 9853KX, 9852KXTW1, 9853KXTW1, 9852KXTW2, 9853KXTW2 4 Atlas Retail Dispenser with Mechanical Display Field Wiring Diagram. 91/8752KX, 91/8753KX, 91/8752KXTW1, 91/8753KXTW1, 91/8752KXTW2, 91/8753KXTW2 5 Atlas Commercial Dispenser with Electronic Display Field Wiring Diagram. 9840KX 6 Atlas Commercial Dispenser with Electronic Display Field Wiring Diagram. 9850KX 1 2 3 Used On Atlas Retail and Commercial Dispensers with Mechanical and Electronic Displays. Field Wiring Diagram Atlas Retail / Commercial Dispensers Electronic and Mechanical Units Sheet 1 of 6 07/07 FE-356G MODELS: 8852KX, 8853KX, 8852KXTW1, 8853KXTW1, 8852KXTW2, 8853KXTW2 ELECTRONICS CABINET MAIN JUNCTION BOX FIELD WIRING CONDUIT T17448-GX VARISTOR ASSEMBLY GRN-18GA GRN-18GA BLK-18GA WHT-18GA NOTE: Pump handle goes to M01598 and Pulser goes to M05200. Earth Ground Screw Terminal 3. RED-18GA YEL-18GA BLK-18GA NEUTRAL 115V OR 230V W CONTROL VALVE A 115V A-14 BLU-18GA A-8 YEL-18GA A-10 G/Y-18GA MAIN BREAKER B A-2 BLK-18GA A-13 WHT-18GA A-6 RED-18GA TO CONSOLE DATA “A”/DATA IN DATA OUT B-SIDE VALVES WIRED SAME AS A-SIDE 3. LIGHTS-NEUTRAL LIGHTS 115V OR 230V MAIN CONDUIT M04850A002 STP CONTROL A SLOW DOWN VALVE A 5 4 MAIN VALVE A EARTH GROUND CD MODULE 115/230 VAC B-6 RED-18GA B-8 YEL-18GA B-14 BLU-18GA CD MODULE-NEUTRAL STP A 3 1 2 8 STP B MAIN VALVE B 9 6 SLOW DOWN VALVE B 7 A-19 W/BLK-18GA 2 WIRE A-9 W/R-18GA J402-2 DATA IN J402-1 DATA OUT SP-1 YEL-18GA (SPARE) SP-2 YEL-18GA (SPARE) LIGHTS BREAKER 15. J401 NOTE: J400 connects to P120 or P220 to match incoming AUTH voltage (P120 is for 120 VAC, P220 is for 220 VAC). SPARE SPARE AUTH-A BRN 1 2 J400 AUTH-B BRN A11 (WHT) A1 (BLK) J402 (To Pump Control Board) J403-1 J403-3 WHT-18GA BLK-18GA BALLAST (115V OR 230V) L2 N L1 GND RETAIL ELECTRONIC UNIT BLU-18GA BLU-18GA RED-18GA J403 P403 PENNY 1 PULSE 1 RTN NOTE: Control System Setup. For Money, use Penny and Penny Return and for Volume, use Pulse and Pulse Return. PULSE 1 PENNY 2 RTN PENNY 2 PULSE 2 RTN PULSE 2 PENNY 1 RTN WHT-18GA PENNY 1 WHT-18GA PULSE 1 RTN WHT-18GA PULSE 1 WHT-18GA PENNY 2 RTN WHT-18GA PENNY 2 WHT-18GA PULSE 2 RTN WHT-18GA PULSE 2 M05189A004 M05718A001 4 J404A M05189A004 M05718A001 4 J404B P404A/B Symbols Chart L2 N L1 Wire Nut Crimped Wire Nut 2. SYSTEM EARTH GROUND LOAD CENTER 115/230 VAC SINGLE PHASE 50/60 HZ NOTES: 1. Dual sided unit shown. For single sided unit make side 1 connections and cap side 2 wiring. All unused wiring must be properly capped. 2. On all 8800K models, if Pulse-out mode is not being used, the AUTH lines must remain open. 5 TO P301A RETAIL PULSE OUT PCA 5 TO P301B RETAIL PULSE OUT PCA J301 P404A/B 22. EMERGENCY POWER CUTOFF GND 1. WHT-18GA DC CONDUIT M05189A004 PENNY 1 RTN Earth Ground Screw Terminal This Sheet Atlas Retail Dispenser with Electronic Display Pulse-out Field Wiring Diagram. Earth Ground No Connection Connection J301 Wire Color Chart Black Brown Red Orange Yellow Green Blue Violet Gray White White with blac k stripe White with red stripe Green with y ellow stripe BLK BRN RED ORA YEL GRN B LU VIO GRA WHT W/B W/R G/Y Field Wiring Diagram Atlas Retail / Commercial Dispensers Electronic and Mechanical Displays Sheet 2 of 6 07/07 FE-356G MODELS: 9852KX, 9853KX, 9852KXTW1, 9853KXTW1, 9852KXTW2, 9853KXTW2 L2 N L1 GND COMMERCIAL ELECTRONIC UNIT P1 2 3 4 1 2 3 4 1 P2 6 7 8 5 6 7 8 5 FIELD WIRING CONDUIT WHT WHT WHT WHT WHT WHT WHT WHT PU GND +5V ADAPTER MAIN JUNCTION BOX MAIN CONDUIT DISPENSER BREAKER SIDE 1 3. YEL A8 A14 NEUT - A YEL BRN AUTH - A A6 MOTOR 1 FEED BLU RED MOTOR 1 HOT MOTOR 1 FEED MOTOR 2 FEED BLK ORA MOTOR 2 HOT MOTOR 2 FEED WHT G/Y A13 A10 SEE NOTES 10 AND 11 3. 12. 12. BRN ELECTRONICS PLATFORM ASSEMBLY AUTH A MICRO BREAKER SIDE 1 A2 G/Y A1 A11 LIGHTS BREAKER SEE NOTES 10 AND 11 3. AUTH B BRN YEL LIGHTS-NEUTRAL BRN YEL WHT BLK 115V OR 230V B6 AUTH - B B8 B14 NEUT - B DISPENSER BREAKER SIDE 2 2 OUT/SIDE PULSE 1 PULSE 2 RETURN NC PULSE 1A PULSE 1B PUL 1A RETURN PUL 1B RETURN OR OR DC FIELD CONDUIT NC NC NC NC Symbols Chart Wire Nut N L1 L2 GND EMERGENCY POWER CUTOFF Crimped Wire Nut 2. SYSTEM EARTH GROUND DC WIRES LOAD CENTER 115/230 VAC SINGLE PHASE 50/60 HZ NOTE: Dual sided unit shown. For single sided unit make side 1 connections and cap side 2 wiring. All unused wiring must be properly capped. This Sheet Atlas Commercial Dispenser with Electronic Display Field Wiring Diagram. Earth Ground Screw Terminal Earth Ground No Connection Connection DC CONDUIT RED GRN WHT BLK GRN WHT BLK BRN ORG YEL GRA BRN ORG YEL GRA PUL I/F PULSE 2A PULSE 2B PUL 2A RETURN PUL 2B RETURN RS-485 I/F 1 OUT/SIDE NC NC NC NC 1. Earth Ground Screw Terminal PUMP I/F 3. T17448-GX Varistor Assembly AIR GAP BARRIER GRN GRN Wire Color Chart Black Brown Red Orange Yellow Green Blue Violet Gray White White with black stripe White with red stripe Green with yellow stripe BLK BRN RED ORG YEL GRN BLU VIO GRA WHT W/B W/R G/Y Field Wiring Diagram Atlas Retail / Commercial Dispensers Electronic and Mechanical Displays Sheet 3 of 6 07/07 FE-356G MECHANICAL UNIT MODELS: 91/8752KX, 91/8753KX, 91/8752KXTW1, 91/8753KXTW1, 91/8752KXTW2, 91/8753KXTW2 RED L2 N L1 GND YEL MAIN FIELD WIRING CONDUIT BLK CONDUIT 3. 18 WHT 18 ORA 14 RED DISPENSER SIDE 1 BREAKER 14 BLK 18 BRN CONDUIT 3. LIGHTS BREAKER 18 BRN/WHT BLK 18 YEL/WHT WHT CONDUIT 18 BLU LIGHT ASSEMBLY 18 BLU 18 BRN 14 BLK MAIN JUNCTION BOX 14 RED 3. 18 ORA 18 WHT DISPENSER SIDE 2 BREAKER YEL RED BLK A WIRE MARKER IS WRAPPED AROUND THE SIDE ONE PULSER (LEFT SIDE) FOR TWIN HOSE OUTLETS 19 ELECTRONIC PULSER WIRING PULSE + 12V P OWER REED PULSER WIRING PULSER 100:1 DC G R OUND EARTH GROUND PULSER 100:1 DC G R OUND EARTH GROUND 1.. EMERGENCY POWER CUTOFF N L1 L2 GND SYSTEM EARTH GROUND LOAD CENTER 115/230 VAC SINGLE PHASE 50/60 HZ Symbols Chart Wire Nut NOTE: Dual sided unit shown. For single sided unit make side 1 connections and cap side 2 wiring. All unused wiring must be properly capped. This Sheet Atlas Retail Dispenser with Mechanical Display Field Wiring Diagram. ORA ORA/WHT GRN CON TACT CLOSURE EARTH GROUND PULSER 10:1 2nd PULSER FOR 2nd HOSE OUTLET (TWIN ONLY) Wire Color Chart 2nd PULSER FOR 2nd HOSE OUTLET (TWIN ONLY) 2. PULSER 10:1 JUNCTION BOX JUNCTION BOX PULSE + 12V P OWER ORA ORA/WHT GRN CONTACT CLOSURE EARTH GROUND Earth Ground Screw Terminal Earth Ground No Connection Connection Black Br own Red O range Yellow Green Blue Violet G ray White White with black st ripe White with red stripe Green with yello w stripe BLK BRN RED ORA YEL GRN BLU VIO GRA WHT W/B W/R G/Y Field Wiring Diagram Atlas Retail / Commercial Dispensers Electronic / Mechanical Display Sheet 4 of 6 07/07 FE-356G MODEL: 9840KX L2 N L1 GND COMMERCIAL ELECTRONIC UNIT P1 2 3 4 1 2 3 4 1 P2 6 7 8 5 6 7 8 5 WHT WHT WHT WHT WHT WHT WHT WHT PU GND +5V ADAPTER FIELD WIRING CONDUIT MAIN JUNCTION BOX MAIN CONDUIT DISPENSER BREAKER SIDE 1 YEL 3. A8 A14 NEUT - A YEL BRN AUTH - A A6 BLU RED MOTOR 1 HOT MOTOR 1 FEED BLK ORA MOTOR 2 HOT MOTOR 2 FEED WHT G/Y A13 A10 SEE NOTES 10 AND 11 3. 12. MOTOR 1 FEED BRN ELECTRONICS PLATFORM ASSEMBLY MICRO BREAKER SIDE 1 A2 G/Y A1 A11 LIGHTS BREAKER 3. BRN YEL LIGHTS-NEUTRAL BRN YEL WHT BLK 115V OR 230V B6 AUTH - B B8 B14 NEUT - B PUMP I/F 1 OUT/SIDE 2 OUT/SIDE PULSE 1A OR PULSE 1B PUL 1A RETURN PUL 1B RETURN RS-485 Earth Ground Screw Terminal RED OR Symbols Chart Wire Nut L2 N L1 GND EMERGENCY POWER CUTOFF Crimped Wire Nut 2. SYSTEM EARTH GROUND LOAD CENTER 115/230 VAC SINGLE PHASE 50/60 HZ NOTE: Make side 1 connections and cap side 2 wiring. All unused wiring must be properly capped. This Sheet Atlas Commercial Dispenser with Electronic Display Field Wiring Diagram. Earth Ground Screw Terminal Earth Ground No Connection Connection RED GRN WHT BLK GRN WHT BLK BRN ORG YEL GRA BRN ORG YEL GRA PUL I/F NC NC NC NC 1. DC CONDUIT DC WIRES I/F PULSE 1 NC RETURN NC DC FIELD CONDUIT T17448-GX Varistor Assembly AIR GAP BARRIER GRN GRN Wire Color Chart Black Brown Red Orange Yellow Green Blue Violet Gray White White with black stripe White with red stripe Green with yellow stripe BLK BRN RED ORA YEL GRN BLU VIO GRA WHT W/B W/R G/Y Field Wiring Diagram Atlas Retail / Commercial Dispensers Electronic and Mechanical Displays Sheet 5 of 6 07/07 FE-356G MODEL: 9850KX BLU VIO ORA BRN L2 N L1 GND COMMERCIAL ELECTRONIC UNIT BLU VIO ORA BRN Earth Ground Screw Terminal FIELD WIRING CONDUIT GRN GRN T17448-GX Varistor Assembly WHT BLK DISPENSER BREAKER SIDE 1 3. 20. AUTH A MICRO BREAKER SIDE 1 SEE NOTES 10 AND 11 3. 12. 12. LIGHTS BREAKER MOTOR 1 FEED MOTOR 2 FEED SEE NOTES 10 AND 11 3. AUTH B LIGHTS-NEUTRAL 115V OR 230V 20. DISPENSER BREAKER SIDE 2 3. 5. PUMP I/F 1 OUT/SIDE *2 OUT/SIDE PULSE 1 NC RETURN NC PULSE 1A PULSE 1B PUL 1A RETURN PUL 1B RETURN OR DC FIELD CONDUIT RS-485 OR *Single sided units only EMERGENCY POWER CUTOFF Symbols Chart L2 N L1 GND 1. Wire Nut Crimped Wire Nut 2. SYSTEM EARTH GROUND LOAD CENTER 115/230 VAC SINGLE PHASE 50/60 HZ NOTE: Dual sided unit shown. For single sided unit make side 1 connections and cap side 2 wiring. All unused wiring must be properly capped. This Sheet Atlas Commercial Dispenser with Electronic Display Field Wiring Diagram. Earth Ground Screw Terminal Earth Ground No Connection Connection Wire Color Chart Black Brown Red Orange Yellow Green Blue Violet Gray White White with black stripe White with red stripe Green with yellow stripe BLK BRN RED ORA YEL GRN BLU VIO GRA WHT W/B W/R G/Y Field Wiring Diagram Atlas Retail / Commercial Dispensers Electronic and Mechanical Displays Sheet 6 of 6 07/07 FE-356G