The Effect of Oxide Layer Thickness on Bond Strength of Porcelain

advertisement

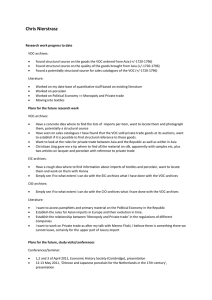

The Effect of Oxide Layer Thickness on Bond Strength of Porcelain to Ni-Cr Alloy Shahin Rezaee Roknia, Hadi Baradaranb Introduction: This study evaluated the effect of four oxidation techniques and porcelain firing on the thickness of oxide layer on base-metal alloy (Ni-Cr) and the relationship of oxide layer to porcelain-metal bond strength. Materials & Methods: This study had an interventional parallel design. Forty plates of base-metal alloy (Ni-Cr) were prepared and divided into four groups to be treated with four different oxidation techniques (A- no oxidation; Boxidation in air; C- oxidation under vacuum; and D- oxidation under vacuum followed by sandblasting). Vita opaque and body porcelain were applied on one side of the plates and baked in a furnace (Vacumat 200) following the recommended directions. The thickness of the oxide layer was measured by an electron microscope before and after porcelain application. The three-point bend test was used to measure the bond strength between porcelain and metal. The force which caused breakage was recorded by computer. Data were analyzed with a one-way analysis of variance (ANOVA) and the Duncan’s test with a 95% significance level. Results: The mean thickness of oxide layer was statistically different between groups before and after porcelain application (p=0.001<0.05). The Duncan multiple range test demonstrated significant differences in porcelain- metal bond strength between different groups of oxidation. Group D showed the best bond strength and was statistically different from the other groups. Conclusion: Oxidation under vacuum followed by sandblasting seems to control the oxide layer and improve the bond strength of porcelain to Ni-Cr alloy. Key words: Oxide layer, bond strength, porcelain, Ni-Cr alloy. Journal of Mashhad Dental School, Mashhad University of Medical Sciences, 2007; 31(Special Issue): 17-21. eramic-metal restorations combine the beauty of porcelain and the strength of a metal substructure. The success and predictability of bonding porcelain to gold base alloys are well documented.1-4 Unfortunately, the cost of gold base alloys for bonding porcelain has increased to such an extent that the future use of the porcelain-gold system is severely jeopardized. Accordingly, interest has been renewed in the non-precious metal alloys as a substitute for gold. However, during the past few years, the technologic parameters of dental ceramic alloys have incurred changes. Precious metal/ceramic alloys are being challenged by manufacturers of numerous nonprecious alloys who claim superior physical properties for their products. Even though non-precious alloys that have superior mechanical properties include higher modulus of elasticity, sag resistance, longevity, and higher melting temperature, there appears to be an investigative controversy about the bond strength of non-precious alloy systems. Sced and Mclean found that all base metal alloy systems break at the interface but do not break in the porcelain, as is typical for gold alloy systems.5 Moffa and associates determined that the bond C ----------------------------------------------------------------------a Professor, Dept of Prosthodontics, School of Dentistry and Dental Research Center of Mashhad University of Medical Sciences. Mashhad, Iran. E-mail: rokni0rahmani@yahoo.com b Assistant Professor, Dept of Prosthodontics, Dental School, Rafsanjan University of Medical Sciences, Rafsanjan, Iran shear strength of two non-precious alloys fused to ceramco porcelain was between 13,500 and 13,900 PSI, which was comparable to the bond of a gold–ceramic system.6 McClean demonstrated that nickel and chromium oxide decreased the thermal coefficient of expansion of vita porcelain that may induce stresses that could cause failure of non-precious ceramic-metal restorations.7 An oxide layer forms on the surface of most dental porcelain fused to metal alloys (PFM) when they are exposed to oxygen at high temperatures. Whether an alloy is deliberately given an oxidation treatment prior to porcelain application, or whether it oxidizes during the portion of the firing cycle before the flow of the porcelain begins, the fusing porcelain comes into immediate contact with oxide rather than with the metal surface. Various opinions exist as to how this oxide interacts with porcelain during the firing cycle. It is widely believed that the fusing porcelain dissolves away the oxide originally formed and produces an interaction zone responsible for the formation of a bond.8 Pask and Fulrath reported a direct chemical bonding between the porcelain and metal, although they did not reject the possibility of a discrete oxide layer at the interface.9 Certain elements have been shown to accumulate at the porcelain–metal interface. This concentration of elements does not necessarily indicate a discrete oxide layer, and may merely represent a solution of their ions in the interface porcelain. Epitaxy effects or lack of crystallinity would hinder detection of an oxide layer by 18 Journal of Mashhad Dental School, Mashhad University of Medical Sciences, 2007; 31(Special Issue): 17-21. X-ray diffraction, as would the presence of only a very thin layer of the oxide.10-12 However, only oxides present in large quantities, such as Cr2o3, have been positively identified.13 Compounds formed on Ni-Cr alloys during conditions similar to those encountered during dental laboratory practice was identified with Xray diffraction. Oxides of nearly all elements contained by the alloys were found after low temperature (650oC) oxidation, while Ni2o and particularly Cr2o3 were predominant after oxidation at high temperatures (1000oc).14,15 Deftary et al used different methods of pretreatment on noble and base metal alloys to evaluate the effect of these treatments on porcelain-metal bond strength. They found significant differences between different metals and suggested that each alloy should be treated differently.16 Mackert et al reported that the strength of oxide adherence to metal varies in different porcelain fused to metal alloys.17 The fracture strength of repeatedly fired porcelain veneered to high noble and base metal alloy crowns were measured by Barghi et al. The result showed as the number of firings increased, the fracture strength decreased in high noble alloys but did not significantly affect base metal alloys.18 The shear bond strength of porcelain fused to metal was compared in four gold and five non-precious alloys. The bond in non-precious alloys was fairly lower and the fracture type was adhesive in non-precious and cohesive in gold alloys.19 The purpose of this study was to evaluate the influence of the thickness of surface oxide layer in base metal alloys on porcelain–metal bond strength. Materials & Methods Forty plates of Ni-Cr alloy (silver cast* JTC.Fulldent SA, Switzerland) were made from green wax sheet (Krupp Dental Co) with the dimensions of 30×5×0.5 mm. Metal plates were sandblasted with 80 µm aluminum oxide grains and ultrasonically cleaned. Samples were divided into four groups to be treated with different oxidation methods suggested by manufacturers: Group A- no oxidation; Group Boxidation in air; Group C- oxidation under vacuum; Group D- oxidation under vacuum followed by sandblasting with 80 µm aluminum oxide grains at a distant of 20 mm for 10 seconds with a 4 bar force. Samples were oxidized in the furnace (Vacumat 200, Vita Zahnfabrik H. Rauter GmbH & Co, Germany) under the recommended directions for each technique. The thickness of the oxide layer was measured by an electron microscope (SEM) at three definitive points for each specimen (Fig 1). The accuracy of the electron microscope was 0.1 µm. Opaque and body porcelain (Vita VMK 68N, Zahnfabrik H, Rauter, GmbH & Co, Germany) were applied on one side of the plates and fired in the *Ni : Principal content Cr : 12.14% Br : 1.6-1.9% same furnace with the recommended directions for each stage. The thickness of porcelain was adjusted to 1 mm for all specimens, and then they were auto-glazed. At this stage, the thickness of oxide layer was measured at the same definitive points by the electron microscope. Bond strength of porcelain to metal was measured by the three-point bend test in an Instron universal testing machine (Instron Corp, Canton, Mass). For this purpose, test specimens were placed into a special jig that was tightened by two screws at its sides. The machine’s cross head was moved at 0.5 mm speed per minute until the bond between porcelain and metal broke. The force which caused breakage was recorded by computer. Mean values and standard deviations (SD) were calculated for each group before and after porcelain application, and compared by a one-way analysis of variance (ANOVA), with the value of statistical significance set at P=0.05. Multiple comparisons of group means were made using the Duncan’s multiple range test. All data were analyzed with a statistical software package (SPSS/PC, SPSS Inc, Chicago). The same statistical analysis was used to verify the relation between bond strength and the thickness of oxide layer for different oxidation methods. Results First stage result: The one-factor ANOVA indicated a significant difference in the thickness of oxide layer between groups before porcelain application with the confidence of 95% (P =0.001<0.05). The thickness of the oxide layer increased after porcelain application, and there was also a significant difference between the 4 test groups (P=0.001<0.05) (Fig 2). The Duncan’s multiple range test revealed significant difference between groups before and after porcelain application (Table 1). Second stage result: In order to verify and compare the porcelain-metal shear bond strength of the 4 test groups, the one-way ANOVA test was used. This analysis showed statistically significant difference among the groups (P =0.00<0.05) (Fig 3). The Effect of Oxide … (Shahin Rezaee Rokni, et al) 19 a c o o b d o o Fig 1. SEM images of oxide layer A, before oxidation. B, oxidation in air. C, oxidation under vacuum. D, oxidation under vacuum followed by sandblasting. NP Groups Mean oxide layer thickness (0.1µm) (SD) After oxidation A D C B 17.50 (2.85) 21.67 (2.28) 25.34 (3.60) 30.01 (4.01) After porcelain application 56.05 (12.44) 73.21 (18.89) 85.49 (12.39) 100.40 (12.95) Duncan test A * * * D * * C B Oxide layer thickness (0.1) Table 1. Mean values and standard deviations of oxide layer thickness after oxidation and porcelain application and the Duncan multiple range test P 120 100 80 60 40 20 0 * A B C D Groups Fig 2. Comparison of mean oxide layer before and after porcelain application (NP=before) (P=after). 20 Journal of Mashhad Dental School, Mashhad University of Medical Sciences, 2007; 31(Special Issue): 17-21. Bond strengths (MPa) 1800 1600 1400 1200 1000 A B C D Groups Fig 3. Shear bond strength values of the 4 test groups. The Duncan’s multiple range comparison test was used to identify statistical differences between oxidation techniques and porcelain-metal bond strength. The result indicated that group D had the highest bond strength and significant difference with the other groups. There was no significant difference between groups B and C, but these groups were different statistically from group A. The least bond strength was found in group A (Table 2,3). Table 2. Statistical analysis of bond strength Groups A B C D N 10 10 10 10 Duncan’s test Mean Bond strength (Mpa) SD 1153.50 1407.71 1442.94 1655.92 53.3920 59.5603 66.4416 47.2953 A B C * * * * * D Table 3. Comparison of mean oxide layer and bond strength Groups A B C D Mean Oxide layer (0.1µm) After porcelain application 56.05 100.49 85.49 73.21 strength Mean bond (Mpa) 1153.50 1407.71 1442.94 1655.92 Discussion Different factors influence the bond between porcelain and metal; therefore, finding a definitive method to evaluate bond strength is difficult. Surface roughness and contamination affect the mechanical bond. Chemical bond is determined by base elements existing in dental alloys and the wetting ability of alloy by porcelain. Compression bond depends on the geometry of the metal frame and thermal expansion coefficient of metal and porcelain. The most important bond mechanism is a chemical type; and an oxide layer is responsible to adhere porcelain to metal. The metal oxides have been studied extensively and are thought to play an important role in ceramo-metal bonding.20-22 Since all elements in basemetal alloys are able to be oxidized, achieving adequate porcelain-metal bonding is fundamentally a question of controlling the oxide layer formed on the surfaces of the metal. Different methods are suggested for metal oxidation and pretreatment before porcelain firing. In this study, four pretreatment methods, which were recommended by manufacturers, were tested on a basemetal alloy (Ni-Cr); and the thickness of the oxide layer was measured before and after porcelain application by the electron microscope. The results indicated a statistically significant difference in oxide layer thickness between oxidation methods. Oxidation in air showed the thickest oxide layer. Baran found the same result.15 The oxide on the surface of the metal provided a bridging link for adherence of the porcelain to the metal.23,24 The bond between oxide and porcelain was strong but the loss of oxide adherence to the metal substrate could cause separation of porcelain. The formation of excessive oxide layers was found to be enhanced by repeated firings of the base metal alloys. 25,26 The oxide layer thickness increased significantly after each stage of porcelain firing in the current study (Table 1). In an in vitro study, the bond strength of a titaniumporcelain system in two firing conditions was evaluated and compared with a Ni-Cr alloy. The result showed the Ni-Cr conventional porcelain fired in an argon atmosphere had significantly higher bond strength. The SEM-EDS analysis of the metal oxide region revealed that the amount of Ni2o and Cr2o3 was less in the argonfired specimens than in the vacuum-fired ones.27 Pask and Tomsia using Ni-Cr alloys, and Wanger et al using palladium alloys found that vacuum firing resulted in an excessive oxide layer thickness and an argon atmosphere limited the oxide formation at the metal-porcelain interface.28,29 Sandblasting has been shown to affect oxide layer thickness; the oxide layer formed before sandblasting differed from the one obtained after sandblasing.30 Sandblasted samples had significantly higher beam failure loads than non sandblasted samples which showed detachment of the porcelain from the metal.31 In this current study, the mean thickness of oxide layer was increased after firing under vacuum and decreased after sandblasting for 10 seconds with a 4 bar force. The amount of force required for the fracture of the porcelain applied to the samples was significantly different between groups, and the result indicated that there was a relation between oxide layer thickness and porcelain to metal bond strength (Table 3). In group A (no oxidation technique), a thin oxide layer was present, and this resulted in the least bond strength. When the thickness of oxide layer was controlled by oxidation under vacuum followed by sandblasting, bond strength was the highest. Oxidation in air resulted in a thick oxide layer and lower bond strength in comparison with oxidation under vacuum. Excessive oxidation of the alloy could lead to fracture through the metal oxide. The The Effect of Oxide … (Shahin Rezaee Rokni, et al) Ni-Cr alloys were expected to exhibit more oxidation than noble alloys.32 It has been noted that an ideal bonding oxide should consist of a monomolecular layer of oxide that is part of the metal and the porcelain.9 The current study confirmed that the oxide layer should be controlled to improve bond strength. Conclusion Within the parameters of this study, the following conclusions were drawn: 1. The thickness of oxide layer was increased after oxidation. The greatest thickness resulted from oxidation in air. 2. After porcelain application, the oxide layer was sequentially increased. 3. There was a statistically significant relation between the oxide layer and bond strength. 4. Degassing in vacuum followed by sandblasting improved the bond strength of porcelain to basemetal alloy. Acknowledgment The authors wish to acknowledge the support given by the Mashhad University of Medical Sciences. References Kelly M, Asgar K, O’brien WJ. Tensile strength determination of the interface between porcelain fused to gold. J Biomed Mater Res 1969; 3: 403-8. 2. Mclean JW, Sced IR. The gold alloy/porcelain bond. Trans Br Ceramic Soc 1973; 5: 229-38. 3. Nielse JP, Tuccillo JJ. Calculation of interface stress in dental porcelain bonded to gold substrate. J Dent Res 1972; 51: 1043-7. 4. Nishiyama Y, Hisashi H, Noguchi H. Various factors affecting the bonding strength of porcelain fused to gold alloys. Trans Bull Tokyo Dent Coll 1971; 12: 99-116. 5. Sced IR, Mclean JW. The strength of metal ceramic bonds with base metals containing chromium (a preliminary report). Br Dent J 1972; 2: 232-4. 6. Moffa J, Lugassy AA, Guckes AD, Gettleman L. An evaluation of non-precious alloys for use with porcelain veneers. Part 1. Physical Properties. J Prosthet Dent 1973; 30: 424-31. 7. Mclean JW. The search for improved metal-ceramics. Quint Dent Tech 1978; 2: 51-9. 8. King BW, Tripp HP, Duckworth WH. Nature of adherence of porcelain enamels to metals. J Am Ceram Soc 1959; 42: 504-25. 9. Pask JA, Fulrath RM. Fundamentals of glass to metal bonding VIII, nature of wetting and adherence. JAM Ceram Soc 1962; 45: 592-5. 10. Lautenschlager EP, Greener EH, Elkington WE. Microprobe analyses of gold-porcelain bonding. J Dent Res 1969; 48: 120610. 11. Anusavice KJ, Ringle RD, Fairhurst CW. Bonding mechanism evidence in a ceramic non-precious alloy system. J Biomed Mater Res 1977; 11: 701-9. 21 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 1. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. Nally JN, Meyer JM. Chemico-physical analysis and mechanical tests of the ceramo- metalic complex. Int Dent J 1968; 18: 309-25. Mackert JR, Ringle RD, Fairhurst CW. Oxide wrinkling and porcelain adherence on non-precious alloys. J Am Dent Assoc 1981; 60: 377-81. Baran GR. Oxidation kinetics of some Ni-Cr alloys. J Dent Res 1983; 62: 51-5. Baran GR. Oxide compounds on Ni-Cr alloys. J Dent Res 1984; 63: 1332-4. Deftary FD, Onovan T. The effect of four pretreatment technique on porcelain to metal bond strength. J Prosthet Dent 1986; 56: 535-9. Mackert JR, Parry EE, Hashinger DT, Fairhurst CW. Measurement of oxide adherence to PFM alloy. J Dent Res 1984; 63: 1335-9. Barghi N, Whitmer MM. Comparison of fracture strength of porcelain- veneered to high noble and base metal alloys. J Prosthet Dent 1987; 57: 23-6. Uusalo EK, Lassila VP, Yil-Urpo AU. Bonding of dental porcelain to ceramic-metal alloys. J Prosthet Dent 1987; 57: 268. Carr AB, Brantley WA. New high-palladium casting alloys: Part 1. Overview and initial studies. Int J Prosthod 1991; 4: 265-75. Papazoglou E, Brantley WA, Mitchell JC, Cai Z, Carr AB. New high-palladium cast alloys:studies of interface with porcelain. Int J Prosthodont 1996; 9: 315-22. Volpe C, Cascone PJ, Cadoff I. Oxidation kinetics of palladium alloyed with gallium, indium, and silver. J Dent Res 1993; 72: 305-8. Anthony DH, Burnett DL. Shear test for measuring bonding in cast gold – alloy – porcelain systems. J Dent Res 1970 ; 49 : 27 Shell JS, Nielsen JP. Study of the bond between gold alloys and porcelain. J Dent Res 1962; 41: 1424-8. Rosenstiel SF, Land MF, Fugimoto J. Metal-Ceramic Restorations. Contemporary fixed prosthodontics, 3rd ed. St. Louis: Mosby; 2001. P. 617-20. Warpeha WS, Goodkind RJ. Design and technique variables affecting fracture resistance of metal ceramic restorations. J Prosthet Dent 1976; 35: 291-8. Atsü S, Berksun S. Bond strength of three porcelains to two forms of titanium using two firing atmospheres. J Prosthet Dent 2000; 84: 567-74. Pask JA, Tomsia AP. Oxidation and ceramic coatings on 80 Ni 20 Cr alloys. J Dent Res 1988; 9: 1164-71. Wagner WC, Asgar K, Bigelow WC, Flinn RA. Effect of interfacial variables on metal-porcelain bonding. J Bimed Mater Res 1988; 27: 531-7. Brantley WA, Cai Z, Papazoglou E, Michell JC, Kerber SJ, Mann GP. X-Ray diffraction Studies of oxidized high palladium alloys. Dent Mater 1996; 12: 333-41. Hofstede TM, Ercoli C, Grac\er GC, Tallents RH, Moss ME, Zero DT. Influence of metal surface finishing on porcelain porosity and beam failure loads at the metal-ceramic interface. J Prosthet Dent 2000; 84: 309-17. Mclean JW. The strengthening of Dental porcelain. The science and art of dental ceramics, volum1, 1st ed. Chicago: Quintessence Publishing Co; 1979. P. 79.