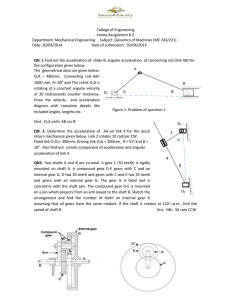

Power Transmission Elements II

advertisement