Installation Instructions RT5R Relight Assembly READ AND

advertisement

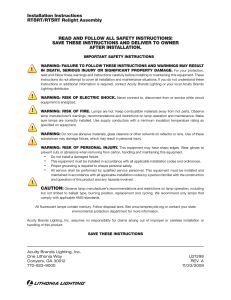

Installation Instructions RT5R Relight Assembly READ AND FOLLOW ALL SAFETY INSTRUCTIONS! SAVE THESE INSTRUCTIONS AND DELIVER TO OWNER AFTER INSTALLATION. IMPORTANT SAFETY INSTRUCTIONS WARNING: FAILURE TO FOLLOW THESE INSTRUCTIONS AND WARNINGS MAY RESULT IN DEATH, SERIOUS INJURY OR SIGNIFICANT PROPERTY DAMAGE. For your protection, read and follow these warnings and instructions carefully before installing or maintaining this equipment. These instructions do not attempt to cover all installation and maintenance situations. If you do not understand these instructions or additional information is required, contact Acuity Brands Lighting or your local Acuity Brands Lighting distributor. WARNING: RISK OF ELECTRIC SHOCK. Never connect to, disconnect from or service while circuit equipment is energized. WARNING: RISK OF FIRE. Lamps are hot. Keep combustible materials away from hot parts. Observe lamp manufacturer’s warnings, recommendations and restrictions on lamp operation and maintenance. Make sure lamps are correctly installed. Use supply conductors with a minimum insulation temperature rating as specified on equipment. WARNING: Do not use abrasive materials, glass cleaners or other solvents on reflector or lens. Use of these substances may damage fixture, which may result in personal injury. WARNING: RISK OF PERSONAL INJURY. This equipment may have sharp edges. Wear gloves to prevent cuts or abrasions when removing from carton, handling and maintaining this equipment. • Do not install a damaged fixture. • This equipment must be installed in accordance with all applicable installation codes and ordinances. • Proper grounding is required to ensure personal safety. • All service shall be performed by qualified service personnel. This equipment must be installed and maintained in accordance with all applicable installation codes by a person familiar with the construction and operation of this product and any hazards involved. CAUTION: Observe lamp manufacturer’s recommendations and restrictions on lamp operation, including but not limited to ballast type, burning position, replacement and cycling. We recommend only lamps that comply with applicable ANSI standards. All fluorescent lamps contain mercury. Follow disposal laws. See www.lamprecycle.org or contact your state environmental protection department for more information. Acuity Brands Lighting, Inc. assumes no responsibility for claims arising out of improper or careless installation or handling of this product. SAVE THESE INSTRUCTIONS Acuity Brands Lighting, Inc. One Lithonia Way Conyers, GA 30012 770-922-9000 U21299 REV. A 4/17/2008 Class R Type II Reflector Retrofit Kit Installation Instructions for Fixture Conversion Retrofit Classified by Underwriters Laboratories, Inc. Reflector Kit Type II: Reflector installation or replacement Lamp holder relocation, removal or replacement Ballast relocation, removal, replacement or addition Installation Instructions The installation of the Class R reflector kit Type II shall be performed by qualified personnel by completing the steps listed below. This retrofit kit will consist of: (2) end brackets (1) light engine with prewired ballast and sockets (ballast will be Class P with UL approvals and wiring diagrams on label) (1) splice box (1) trim assembly and mounting hardware consisting of: (7) #8 self-drilling TEK screws (2) #8 x .25 screws Job packs will have screws bulk-packed with each pallet of kits. Verify the contents of the retrofit kit by using the diagram below. End Brackets Splice Box Light Engine Trim Step One: Remove existing components from host fixture. Locate the fluorescent lighting fixture that is to be retrofitted. Turn off power. WARNING: Electrical shock can occur during retrofit component installation if power is not turned off. WARNING: Installation of this retrofit assembly requires a person familiar with the construction and operation of fluorescent luminaire electrical system and the hazard involved. WARNING: Unless otherwise indicated, do not make or alter any opening in the compartment of wiring or electrical components during installation of this retrofit assembly. WARNING: Ensure that existing fixture is and remains properly connected to building ground. Use of any other than Lithonia Lighting supplied screws to install assembly may result in ungrounded fixture components. Remove existing louver, lamps and channel cover. Identify power supply wires to disconnect. Follow installation step 2 wiring option A or B based on incoming supply wire. Remove ballast, sockets and lampholder bracket. Recycle or properly dispose of all components removed from host fixture. Step Two: Install relight assembly. Install end brackets to 2’ length (socket side) of fixture. Install end bracket assembly by inserting bottom flange between bottom of fixture end plate and tee-bar. Center end bracket and attach using two 8-32 self-drilling TEK screws through the small holes at the top of the bracket (provided). Repeat on opposite end of fixture as shown. Hang light engine (with lamps and ballast installed) assembly by sliding open slots over the tabs on the universal brackets as shown with ballast facing the back of the host fixture. FLANGE SITS ON T-BAR BENEATH FIXTURE REFLECTOR HANGING TABS END BRACKET FLANGE SITS ON T-BAR BENEATH FIXTURE OLD BALLAST INPUT LEADS TEK SCREWS GROUND STRAP TEK SCREW BDP LIGHT ENGINE TEK SCREWS REFLECTOR HANGING TABS END BRACKET Option A: Fixture supply wire is (2) #18AWG solid 1) Remove splice to existing ballast. 2) Connect #18AWG black and white to RT5R ballast disconnect. Option B: Fixture supply wire is any other than (2) #18 AWG solid 1) Cut ballast input leads 6" from splice and strip lead to 3/8". 2) Connect #18 AWG black and white (old ballast input lead) to RT5R ballast disconnect. 3) Install splice box to cover input wire splice, using two TEK screws. SPLICE BOX GROUND STRAP TEK SCREW BDP TEK SCREWS LIGHT ENGINE Make wire connections and ground assembly to host fixture per option A or B based on existing fixture supply wire. Rotate light engine up to horizontal position and secure to opposite end brackets with two TEK screws (provided). Trim hinges and latches from either side. Simply slide hinge into slot’s universal bracket assembly, close door and engage cam latches. Help save our environment by recycling all remaining components. Save these instructions.