CFT540 LED Brochure - WE-EF

advertisement

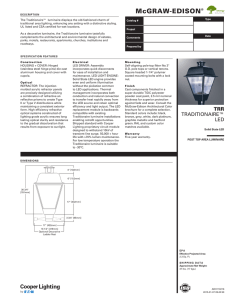

WE-EF LEUCHTEN Post Top Luminaire CFT540 2015 Design and Engineering The most important element in the design process is the development of luminaires that Through continual investment in tooling, production processes and the ongoing encompass timeless design; in other words, design that best reflects their enduring education of our employees, we are able to achieve the highest standards of quality. qualities. In exterior lighting, the corrosion resistance qualities of a product are important for their In addition, state-of-the-art engineering brings with it the highest standards with regard to environmentally-friendly materials and processes, i.e., high IP ratings, excellent thermal management and innovative optical systems. The development of high-end, efficient reflectors and lenses is one of the core competencies of WE-EF. This means compliance with international lighting and safety norms, while meeting the criteria of such organisations as the Dark Sky Society. Continual investment in research and development is the basic condition for meeting these requirements. WE-EF innovations, such reliability and longevity. A durable and reliable corrosion protection can only be achieved when Product Development and the Production Processes are considered together. Years of research, development and practical testing and experience in some of the harshest climates on earth has resulted in WE-EF’s unique 5CE corrosion protection system. It encompasses five critical elements; Material, Conversion Coating, Powder Coating, PCS Polymer Coated Stainless Hardware and Process Control. Only complete systems such as 5CE can provide reliability and longevity in exterior environments. as IOS® Innovative Optical Systems, CTA® Cool Touch Adaptor, ASC Anti Slip Coating and Application OLC® One LED Concept, are just some examples of the company’s continuing investment Real and sustainable cost and energy savings can only be achieved through professional in technology. project planning, including the application of the latest optical systems and light Production 'Made by WE-EF' is more than just an expression; the high quality level of in-house production processes includes: sources. In streetlighting applications, for example, this means minimising the number of luminaires required by optimising the efficiency of the optical system, while at the same time limiting glare in line with international standards. In short, reduced installation and maintenance costs, less CO2 and improved quality of light. Tooling for HPDC and injection moulding Aluminium high-pressure die-casting Recycling CNC machining More than 90 per cent of a WE-EF luminaire can be recycled. The main component, Powder Coating a marine-grade aluminium substrate, is refined from recycled aluminium. This recycled Pole manufacturing aluminium is also an 'energy storer'. Only 5 per cent of the original energy needed to Assembly process bauxite into aluminium is required for recycling. In other words, 95 per cent of the original energy input is also recycled. CFT540 Post top luminaire, medium beam distribution, symmetric or rectangular. Light source LED 4000 K, for 3000 K refer to www.we-ef.com IP66. Class I. IK08. Marine-grade, die-cast aluminium alloy. 5CE superior corrosion protection including PCS hardware. Powdercoat finish in RAL 9004, RAL 9006, RAL 9007, RAL 9016 or Classic Silver. Silicone CCG® Controlled Compression Gasket. PMMA RFC® Reflection Free Contour technology. The luminaire is factory sealed and does not need to be opened during installation. Integral EC electronic converter. Factory installed LED circuit board. LED boards can be easily removed for upgrading. CAD optimised OLC® optics for superior illumination and glare control. Advanced thermal management (NTC) on request. Integrated surge protection 6/6 kV (10/10 kV optional). Recommended mounting height 4–6 m, depending on lamp type selected. Light distributions [C50] [R] [C50] [R] [C50] Medium beam distribution, symmetric [R] Rectangular distribution CFT540 Part ID Light source K lm* Factor** kg [C50] 105-0077 [EC] 36 LED 36W / 350 mA 4000 4536 1.00 13.3 105-0079 [EC] 36 LED 72W / 700 mA 4000 8294 1.83 13.3 105-0083 [EC] 36 LED 36W / 350 mA 4000 4536 1.00 13.3 105-0085 [EC] 36 LED 72W / 700 mA 4000 8294 1.83 13.3 [R] ø 700 54 323 ø 76 x 100 ø 102 ø 700 * Nominal lumen output based on LED manufacturers data at 85°C TJ. For rated lumens at 25°C Tq and latest data refer to www.we-ef.com. ** Multiplier for Isolux value FEATURES CFT540 IP classification: IP66 Electrical protection: Class I Impact protection: IK08 Luminaire housing: Marine-grade, die-cast aluminium alloy, 5CE superior corrosion protection Hardware: PCS (Polymer Coated stainless Steel) Cover: PMMA RFC® (Reflection Free Contour) technology Gasket: CCG® (Controlled Compression Gasket) technology ECG: Integrated surge protection 6/6 kV (10/10 kV optional) LED: 36 pieces with 3000 K or 4000 K Optic: OLC® (One LED Concept) technology with [C50] or [R] beam distribution Heat sink: Integrated Installation: Direct mount ø 76 x 100 mm [C50] Symmetric distribution for lighting public spaces and car parks. [R] Rectangular distribution for lighting public spaces and car parks. The OLC® technology is the ideal method for achieving a uniform and energy saving lighting solution, providing highest safety and visual comfort, in ensuring that the failure of individual LEDs does not lead to an adverse affect in the lighting. RFC® technology – engineered with a UV-stabilised PMMA panel which has a contoured surface, contoured in a way that imitates the shape of the LED lens; the goal is to minimise the loss of light that normally occurs due to internal reflection. With the intelligent use of a built-in vent, pressure fluctuations are equalized reliably and less strain is put on the seals, ensuring the sensitive interior electronics are protected against moisture penetration for years to come. Using either a 1-10V or DALI interface with electronic converter, the light output and energy usage of the individual luminaires can be controlled. All components of the luminaire are engineered for reliability and longevity. PCS coated fasteners made from austinetic stainless steel reduce the risk of galvanic corrosion. The CFT540 is fitted with a 6/6 kV surge protection, which is integrated in the LED driver, in accordance with IEC 61643-11. If the surge protector has been triggered by an adverse event, the luminaire is automatically disconnected from the mains. In risk areas we recommend the addition of a 10/10 kV optional WE-EF surge protection SP10 for the luminaire. Important: For comprehensive protection of the luminaire against lightning and electrical surges, we generally recommend primary (Type 1) and secondary (Type 2) surge arrestors be installed into the switch board. New shape for additional design possibilities: The ring-shaped luminaire body of the new CFT540 subsequently led to the development of new LED boards. Outstanding and long lasting anticorrosion properties can only be achieved by a comprehensive, integrated approach. WE-EF's unique 5CE system encompasses 5 Critical Elements: Material, Conversion Coating, Powder Coating, PCS Hardware and Process Control. H: 4,4 m 12 0,2 lx 9 H: 4.4 m 0,7 3,2 6 3 13,6 32,6 m 3 6 9 12 0.2 lx [C50] Symmetric distribution for lighting public spaces and car parks. Maximum angle of peak intensity approximately 50°. Glare index G1 from EN 13201. No light above the 90 degree horizontal (ILE CLASS E1/E0). Typical mounting height 4–6 m. 32.6 lx H: 4,4 m 7,5 5 H: 4.4 m 2,5 20 0 m 0 2,5 5 10 7,5 5 2 1 0,5 lx 10 12,5 15 [R] 0.5 lx Rectangular distribution for lighting public spaces and car parks. Maximum angle of peak intensity approximately 45° and 65°. Glare index G1 from EN 13201. No light above the 90 degree horizontal (ILE CLASS E1/E0). Typical mounting height 4–6 m. 20 lx WE-EF LEUCHTEN GmbH & Co. KG Toepinger Strasse 16 29646 Bispingen Germany Tel + 49 5194 909 0 Fax + 49 5194 909 299 info.germany@we-ef.com www.we-ef.com CFT540 | European Edition | © Copyright WE-EF 2015 | Technical Specifications are Subject to change