15 Minute Misfire Diagnosis

advertisement

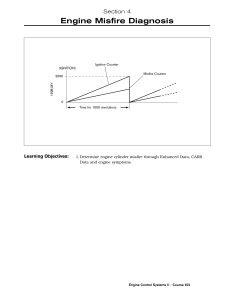

THE NUTS AND BOLTS OF ELECTRICAL DIAGNOSIS 15 Minute Misfire Diagnosis Quick Test Examples on the Toyota 1ZZ-FE by Mike Van Dyke E ngine misfire is one of the more common problems we can be presented with when diagnosing transmission operation on today’s vehicles. Sending misfire problems down the road can mean denying your shop a quick, easy job, and the satisfaction of handing the keys to a smiling customer. An engine misfire can also have potentially damaging effects on the transmission. Think about the jolting and shock load on the input shaft and other splines when a misfire occurs with the torque converter clutch applied. After repairing a transmission with spline or sun gear reaction shell failure, it isn’t uncommon to find out during the road test it has an engine misfire. Recently I had the opportunity to diagnose misfire problems on a couple of Toyota Corollas with 1ZZ-FE engines. The 1ZZ-FE and its variants have been used in several Toyota platforms since its introduction in 1998 and it shares many similar traits with modern engines being produced by other automakers. The 1ZZ-FE is a 1.8 liter, DOHC, 16-valve, 4-cylinder engine, with variable intake valve timing, coilon-plug ignition, and port fuel injection. Many diagnostic approaches taken with this engine can be successfully applied to other automakers’ engines. The first situation was with a 2000 Corolla. The customer complained the transmission was “bumping” or “shifting” when sitting at a stoplight after the vehicle had been driven for a while (engine fully warmed up). 32 32MvD-Misfire.indd 32 Figure 1: Scan data shows only cylinder #3 was misfiring. Figure 2: Switching coils, spark plugs, or even fuel injectors from known good cylinders can help narrow down the problem quickly. GEARS August 2006 7/10/06 3:25:45 PM Windings & terminal connections impervious to contamination Failure 1 Failure 1 Plastic fully encloses lead wire for support Failure 2 Failure 2 Plastic fully surrounds coil Failure 3 Failure 3 Extended Sure-Signal™tip ensures stronger signal OE R AY B E S T O S POWERTRAIN OTHER AFTERMARKET Our patent-pending encapsulated design eliminates limp mode comebacks Maximum Performance. In response to the industry’s need for a dependable solution to faulty speed sensors, Raybestos Powertrain has developed an Output Speed Sensor that is superior, even to OE, in eliminating limp mode comebacks. This patent-pending design is fully encapsulated, completely impervious to moisture and contamination and resistant to cracking. • Plastic fully supports the coil for maximum vibration protection. • Plastic encapsulates the lead wire, terminal and all internal components, making it impervious to contamination. • The extended Sure-Signal™ tip ensures stronger signal. • The Teflon-coated silicone O-ring is color-coded to the application for easy identification. • 100% function tested prior to packaging for reliability. 964 East Market St., Crawfordsville, IN 47933 • Toll Free: 800-729-7763 • Fax: 765-364-4576 • Email: raypt@raybestospowertrain.com raybestos plcd.indd 9 6/1/06 2:38:22 PM 15 Minute Misfire Diagnosis A closer look revealed the culprit spark plug was fouled with deposits. It so happens that when the customer arrived at the shop the symptom was present. A road test with the customer verified the complaint. An initial diagnostic fee was agreed upon and the customer was given a ride home. First I connected a scan tool to check for Diagnostic Trouble Codes (DTC) and to monitor any pertinent scan data. The customer indicated a possible transmission problem, but “seat of the pants” intuition told me to check for a misfire first. No DTCs were present, but, as you can see in figure 1, the misfire counter for cylinder number 3 was incrementing while the other cylinders remained at zero. There wasn’t enough misfire activity to set a DTC, but at least I knew the problem was isolated to cylinder number 3. Rounding Up the Usual Suspects Just for a quick heads up, I had the service writer check prices on the top three suspect components to cause a misfire: • OEM specified Iridium spark plugs: $80 for a set ($20 each) • Ignition coil: $160 • Fuel Injector: $240 Figure 3: A fouling spark plug ended up causing the intermittent misfire. The age-old trick of spraying carburetor cleaner around the intake manifold gasket created no change in the symptom, so I was fairly certain we were dealing with one of our three main suspects. But which part was at fault? And how could I quickly diagnose and be certain of the faulty part, without wasting time and money by replacing unnecessary parts? None of these parts are particularly inexpensive; even the spark plugs at $20 each aren’t cheap when they may not fix the problem. I wanted to make sure to keep the diagnosis and repair process moving smoothly in a positive direction. Throwing Parts at the Problem Some options that ran through my mind were: 1. Get out the COP (Coil-On- What do you need to know? UT-1 UNIT TESTERS Compact, portable, affordable and vital for all transmission shops. Cut unnecessary installation and removal, by testing the hydraulic integrity of individual transmission components. SOLENOID TESTERS A “must” for testing the “weakest link” in the transmission. Easy-to-use. Tests up to six solenoids at a time … each separate from the valve body. Infinitely variable duty cycle control allows precise control of the test. Also connects to AXILINE Electronic Shift (AES). www.superflow.com 34Gears April 2006 QuarterPg HORIZ1 32MvD-Misfire.indd 34 VBT-2000 VALVE BODY TESTERS Precise control! Easy to operate. Quick set-up. Simulates toughest driving conditions while testing electronic, hydraulic and vacuum systems — valve bodies, solenoids and pressure transducers — using actual transmission pressures and heated oil. Computerized TDAC System upgrade optional. 2. 3. Plug) adapters to scope the secondary coil waveform, or probe the primary side of the coil to get clues from firing voltage, burn time, and burn line slope. Scope the injector voltage and current waveforms to get more clues from pintle humps, flyback voltage spike, current ramp, etc. Throw some known good parts at it and see if it works. A few high tech options to really sink your teeth into with today’s test equipment! Options 1 and 2 were very tempting, but option 3 won out for me because I had seen three other cylinders working perfectly, sitting right there under the hood. That means three known good coils, spark plugs, and injectors. AXILINE ELECTRONIC SHIFTERS (AES) Isolate the transmission from the ECU system, simulate and control transmission, valve body, and solenoids — with sequential and/or adaptive process — and eliminate the hassles, inconsistencies and questions raised by cheaper, less reliable hand-held systems using older technology. Pre-programmed software. Easy, instant on-screen read … up to 16 solenoids at a time … in any mix of DC or PWM. When you really need to know… 4060 Dixon Street | Des Moines IA 50313 | ph: 888.442.5546 1 10:13:19 AM GEARS 2/20/06 August 2006 7/10/06 3:26:12 PM Figure 4: A burned exhaust valve was the final straw on this engine. The pistons are clean around the edges, indicating oil consumption from bad rings. Why not just swap coils with neighborly cylinder #2, fire it up, and watch the misfire counter? Or, if I have to, roll up my sleeves and swap spark plugs? I grabbed a 10 mm socket and a speed handle. Two minutes later I had the engine running after switching the coils between cylinders 2 and 3 (figure 2). Number 3 cylinder was still showing misfires. Then I dug in five minutes deeper and switch the spark plugs between cylinders 2 and 3. Ah ha! The misfire moved to cylinder number 2. I installed a set of spark plugs and the problem was solved. The customer was anticipating an expensive transmission repair and was very happy paying for the diagnosis and spark plug replacement instead. A closer look revealed the culprit spark plug was fouled with deposits as shown in figure 3. The other spark plugs were showing excess deposits as well. The customer was informed the deposits could be caused by fuel additives or excessive oil consumption, and the customer did acknowledge the engine was using some oil between changes. A Not-So-Happy Story Another Corolla came in with an obvious misfire. This one had the MIL lit, with DTC P0302 in memory: cylinGEARS August 2006 32MvD-Misfire.indd 35 der 2 misfire detected. Uneven cranking pointed toward a serious mechanical failure of the engine. A compression test showed no compression on cylinder 2. Removing the cylinder head revealed a burned exhaust valve and the pistons were all very clean around the edges, indicating heavy oil consumption and poor piston ring oil control (figure 4). The engine had over 200,000 miles on it. The customer agreed it wasn’t worth doing a valve job and opted to install a used engine. A misfire can have many possible causes: fuel delivery, spark/ignition, and mechanical engine failure to name the more common ones. Taking the time and knowing how to connect and use high tech test equipment is important when you need to verify the failure of an expensive component or track down an elusive problem in a circuit. But on many occasions the basics can be covered by applying some quick tests or substitutions like the ones we went over here. Sometimes it helps to think simple first before moving on to the more complicated or high tech approach. The right product at the right time… That’s how we built our family core business, In fact, we still operate our business that way. And using that as our cornerstone we’ve grown over the years into a true “Partner to the Professional Rebuilder”. We have a large inventory of import and domestic core units…, and we can get them to you fast! Chicago 4050 S. Wentworth Ave. Chicago IL 60609 (800) 826-7403 (773) 624-6111 (773) 624-6660 (fax) www.aaeq.net Las Vegas 2580 N Commerce St. N Las Vegas, NV 89030 (800) 426-8771 (702)649-7776 (702) 649-6777 (fax) e-mail: sales@aaeq.net 35 7/10/06 3:26:30 PM