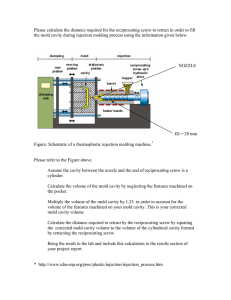

Molding Guide

advertisement