Enable trouble-free service and longer product life

advertisement

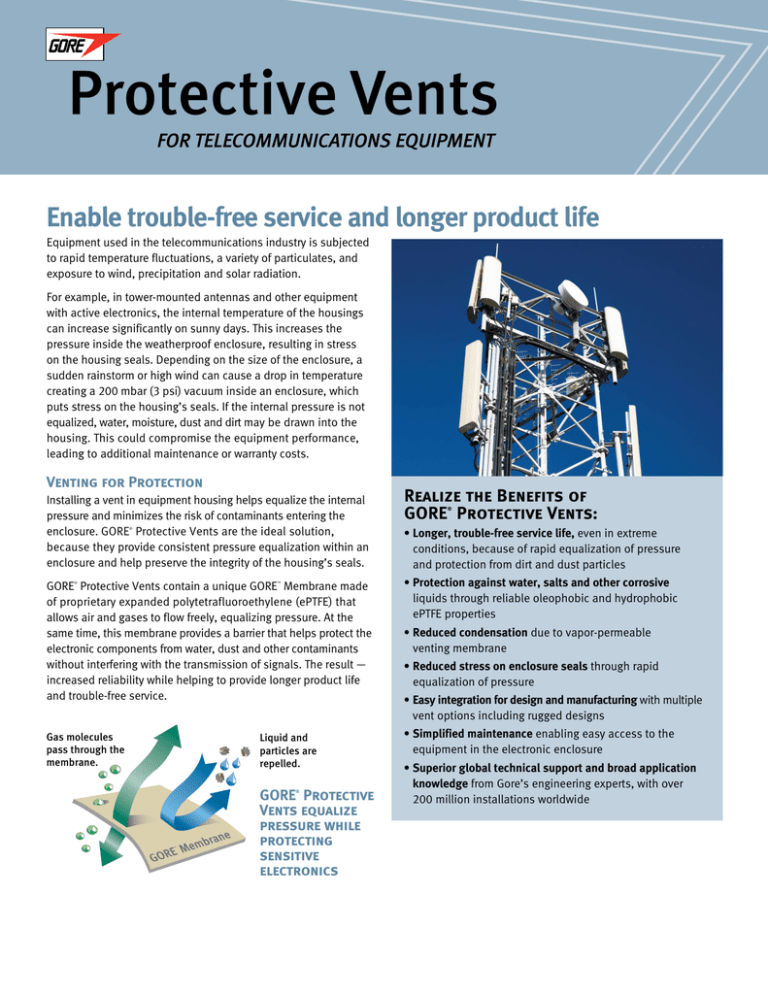

Enable trouble-free service and longer product life Equipment used in the telecommunications industry is subjected to rapid temperature fluctuations, a variety of particulates, and exposure to wind, precipitation and solar radiation. For example, in tower-mounted antennas and other equipment with active electronics, the internal temperature of the housings can increase significantly on sunny days. This increases the pressure inside the weatherproof enclosure, resulting in stress on the housing seals. Depending on the size of the enclosure, a sudden rainstorm or high wind can cause a drop in temperature creating a 200 mbar (3 psi) vacuum inside an enclosure, which puts stress on the housing’s seals. If the internal pressure is not equalized, water, moisture, dust and dirt may be drawn into the housing. This could compromise the equipment performance, leading to additional maintenance or warranty costs. Venting for Protection Installing a vent in equipment housing helps equalize the internal pressure and minimizes the risk of contaminants entering the enclosure. GORE Protective Vents are the ideal solution, because they provide consistent pressure equalization within an enclosure and help preserve the integrity of the housing’s seals. ® GORE Protective Vents contain a unique GORE Membrane made of proprietary expanded polytetrafluoroethylene (ePTFE) that allows air and gases to flow freely, equalizing pressure. At the same time, this membrane provides a barrier that helps protect the electronic components from water, dust and other contaminants without interfering with the transmission of signals. The result — increased reliability while helping to provide longer product life and trouble-free service. ® Gas molecules pass through the membrane. ™ Liquid and particles are repelled. GORE Protective Vents equalize pressure while protecting sensitive electronics ® Realize the Benefits of GORE Protective Vents: ® •Longer, trouble-free service life, even in extreme conditions, because of rapid equalization of pressure and protection from dirt and dust particles •Protection against water, salts and other corrosive liquids through reliable oleophobic and hydrophobic ePTFE properties •Reduced condensation due to vapor-permeable venting membrane •Reduced stress on enclosure seals through rapid equalization of pressure •Easy integration for design and manufacturing with multiple vent options including rugged designs •Simplified maintenance enabling easy access to the equipment in the electronic enclosure •Superior global technical support and broad application knowledge from Gore’s engineering experts, with over 200 million installations worldwide Diverse Product Line Engineered for Simple Integration GORE Protective Vents are manufactured in many different sizes and shapes, making it easy to choose the right vent for any application. With a diverse product portfolio, these vents are easy to integrate into new or existing designs to meet the needs of a broad range of applications and markets. The versatility of GORE Protective Vents is apparent in both their range of protection and their ease of installation. For example, these vents: ® •tolerate temperatures ranging from –40°C to 125°C •perform to protection standards up to IP69K* •provide maximum protection for applications in harsh environments through molded plastic or metal vents ® Base stations Antennas Amplifiers Public address systems (PA) Stationary batteries Radio Frequency Systems’ Tower Mounted Amplifier, used with permission. © Radio Frequency Systems. ® GORE Protective Vents provide value to a wide array of cellular network equipment in the telecommunications industry including: •install easily by being adhered, threaded, snapped, bolted or heat/ultrasonic-welded to a variety of enclosure materials •adhere to the device with adhesive backing for applications with insufficient free space to install a vent inside Proven Application Expertise and Experience With more than fifty years in membrane research and technology, W. L. Gore & Associates, Inc., has combined this expertise with an extensive understanding of electronic device design to create innovative, leading-edge venting solutions. Gore continues to study the design and manufacturing needs of the electronic products industry in areas such as temperature and pressure fluctuations, reliability, testing methods, product standards and performance requirements. international contacts 54.351.4886.427 61.2.9473.6800 55.11.5502.7800 86.21.6247.1999 33.1.5695.6565 49.89.4612.2211 91.22.6691.9225 39.045.6209.240 81.3.3327.0011 Korea Mexico Netherlands Scandinavia Singapore Spain Taiwan United Kingdom USA W. L. Gore & Associates, Inc. 401 Airport Road • Elkton, MD 21921 USA Phone: 410.392.4440 • Toll-Free: 1.800.455.4684 Fax: 410.506.8749 • Email: protectivevents@wlgore.com gore.com/protectivevents 82.2.393.3411 52.81.8288.1281 49.89.4612.2211 46.31.706.7800 65.6733.2882 34.93.480.6900 886.2.8771.7799 44.1506.460123 1.410.392.4440 *IP ratings are product housing design dependent. Please contact a Gore representative for more information. FOR INDUSTRIAL USE ONLY. Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations. The optimal performance of any GORE® Protective Vent depends on how it is handled and incorporated into the final product. This includes such elements as the device design, sealing method, and assembly method. While Gore is able to provide general guidelines based upon our experience with the GORE® Protective Vent, it is ultimately the responsibility of the device manufacturer to validate each product and its performance for its intended application. Contact a Gore technical sales associate today for assistance in determining the best GORE® Protective Vent for your specific application. GORE and designs are trademarks of W. L. Gore & Associates, Inc. All rights reserved. © 2010 W. L. Gore & Associates, Inc. 4998_025_R2_US_JUL10 Argentina Australia Brazil China France Germany India Italy Japan