MEC – Magnetic Eddy Current

advertisement

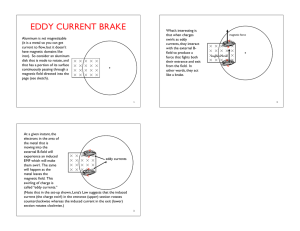

MEC – Magnetic Eddy Current Next Generation SLOFEC Technique Overview Magnetic Eddy Current (MEC) is the next generation of fast corrosion mapping technique based on the further development of the industry proven Saturation Low Frequency Eddy Current (SLOFECTM) technique. The MEC technique is applied to most of Innospection’s next generation of topside and subsea inspection tools to support integrity assurance. MEC – Next Generation SLOFEC The MEC technique is a dynamic electromagnetic scanning technique that combines a direct current magnetic field with an Eddy Current field. By utilising the superimposed direct current magnetisation, the depth of penetration is increased to such an extent that internal defects such as corrosion, pitting and cracks can be detected from the external surface. The key improvement of the MEC technique in comparison to the SLOFECTM technique is that it operates on Magnetic Field Controlled High Frequency Eddy Current. Specifically developed Eddy Current sensors able to generate a higher density Eddy Current field for increased defect detection sensitivity are used. These Eddy Current sensors also enable the measurement and adaptation of the magnetic field strength. By analysing and controlling the magnetic field strength to operate at the retentivity point of the hysteresis curve and combining it with higher operating frequencies, the MEC technique offers enhanced defect detection capabilities including the ability to inspect through higher wall and coating thickness. With an improved signal to noise ratio, the MEC technique has proven to be capable of inspecting through a 35mm fire protective coating for defects beneath. Innospection Limited Unit 1, Howemoss Avenue, Kirkhill Industrial Estate, Dyce, AB21 0GP, Aberdeen, United Kingdom Tel : +44 (0)1224-724744 Fax : +44 (0)1224-774087 Web : www.innospection.com Email : info@innospection.com © Copyright Innospection Ltd 2015. All rights reserved. MEC – Magnetic Eddy Current V1-2015 MEC – Magnetic Eddy Current Next Generation SLOFEC Technique Principle of MEC Technique The MEC technique uses a combination of direct current magnetic field with an Eddy Current field. By utilising the superimposed direct current magnetisation, the depth of penetration is increased to such an extent that the internal defects can be detected from the external surface. While the defects affect the direct current magnetic field lines inside the remaining wall of the inspected object, a change in the relative permeability in the area consequently affects the Eddy Current field lines. The changes in the Eddy Current field lines are measured and analysed against the calibration in terms of the signal amplitude, phase and shape to enable the following evaluations: Differentiation between internal and external defects (Internal defects on the underside produce a vertical signal while defects on the topside produce a horizontal signal) Distinguishing defects from false calls, laminations or inclusions Analysis of defect severity in terms of wall loss Analysis of defect volume Separation of noise signals from defect signals Diagram 1 – Detection of far side defect with corresponding vertical signal response Diagram 2 – Detection of near side defect with corresponding horizontal signal response Innospection Limited Unit 1, Howemoss Avenue, Kirkhill Industrial Estate, Dyce, AB21 0GP, Aberdeen, United Kingdom Tel : +44 (0)1224-724744 Fax : +44 (0)1224-774087 Web : www.innospection.com Email : info@innospection.com © Copyright Innospection Ltd 2015. All rights reserved. MEC – Magnetic Eddy Current V1-2015 Page 2 of 5 MEC – Magnetic Eddy Current Next Generation SLOFEC Technique Through the use of specifically developed high density Eddy Current sensors with sensor adaptation to enable the magnetic field strength measurement, the MEC technique operates at the retentivity point of the hysteresis curve in combination with high frequencies. Diagram 3 – Magnetisation level of the MEC technique As a result, the MEC technique offers higher defect detection sensitivity with the following enhanced technology capabilities: Increased wall thickness range of the inspection object Increased stand-off (coating) range i.e. up to 35mm of fire protective coating without the coating removal Increased frequency range Improved signal to noise ratio Key Features of the MEC Technique As an electromagnetic technique, direct surface coupling between the sensor system and the object to be inspected is not necessary. As a result, the MEC technique can be utilised not only for risk based inspection but also as a Non-Intrusive Inspection (NII) strategy. Innospection Limited Unit 1, Howemoss Avenue, Kirkhill Industrial Estate, Dyce, AB21 0GP, Aberdeen, United Kingdom Tel : +44 (0)1224-724744 Fax : +44 (0)1224-774087 Web : www.innospection.com Email : info@innospection.com © Copyright Innospection Ltd 2015. All rights reserved. MEC – Magnetic Eddy Current V1-2015 MEC – Magnetic Eddy Current Next Generation SLOFEC Technique 1. High defect detection sensitivity and reliability The MEC technique is highly sensitive in the detection of defects such as corrosion and pitting. It is capable of inspecting ferromagnetic and non-ferromagnetic materials such as carbon steel, stainless steel, duplex and super duplex materials with wall thickness up to 42mm. The technique has been proven in the field to be sensitive and reliable in the detection of local corrosion in Page 3 of 5 pipelines, pressure vessels, storage tanks, risers, caissons, subsea pipelines and structures as well as other types of steel constructions. The MEC technique is capable of inspecting through different coatings and cladding types such as Epoxy, CRA, TSA or Monel clad without the coating removal. The maximum inspectable coating thickness to date using the MEC technique is 35mm of fire protective coating. 2. High inspection speed The MEC technique enables the fast screening of large areas with low surface preparation prior to inspection. Cleaning of the inspection surface to the bare metal is not required to produce good quality inspection data which serves as a major advantage over the Ultrasonic technique and makes it uniquely suitable for subsea inspection applications. 3. High inspection temperature range The MEC technique enables the inspection to be performed at high temperatures with experience to date experience of up to 150°C. 4. Distinction between internal and external defects The MEC technique is highly sensitive in the detection of small volumetric defects and is capable in differentiating between internal and external defects. The types of defect profiles detected by the MEC technique include the following: single isolated pits groups of corrosion attack shallow and narrow pits in the early stage of defect development shallow rounded pits with different diameters that are particularly difficult to be detected with conventional manual Ultrasonic Microbiological Induced Corrosion (MIC) Innospection Limited Unit 1, Howemoss Avenue, Kirkhill Industrial Estate, Dyce, AB21 0GP, Aberdeen, United Kingdom Tel : +44 (0)1224-724744 Fax : +44 (0)1224-774087 Web : www.innospection.com Email : info@innospection.com © Copyright Innospection Ltd 2015. All rights reserved. MEC – Magnetic Eddy Current V1-2015 Page 4 of 5 MEC – Magnetic Eddy Current Next Generation SLOFEC Technique 5. Real time scan results with colour mapping for defects The scan results are mapped out in real time which allows for the immediate defect indication of the inspected object. The coloured reporting of the Innospectit Software provides an overview of the condition of the inspected object to enable the evaluation, determination of corrective actions and modifications to future maintenance and inspection strategies. Diagram 4 – Simultaneous Signal Phase and Amplitude Analysis As with all electromagnetic based techniques, the MEC technique is not absolute wall thickness measurement technique. It is a comparison technique which means that a calibration sample as close as possible in the material properties and geometry of the object to be inspected is required for the inspection. Innospection Limited Unit 1, Howemoss Avenue, Kirkhill Industrial Estate, Dyce, AB21 0GP, Aberdeen, United Kingdom Tel : +44 (0)1224-724744 Fax : +44 (0)1224-774087 Web : www.innospection.com Email : info@innospection.com © Copyright Innospection Ltd 2015. All rights reserved. MEC – Magnetic Eddy Current V1-2015 Page 5 of 5