Introduction to Building Automation Systems (BAS)

Introduction to Building

Automation Systems (BAS)

Ryan R. Hoger,

LEED AP

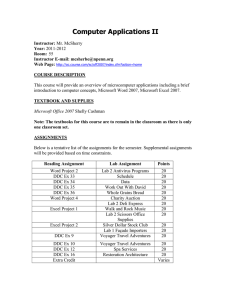

Building Automation Systems z z z z z z z

Centralized controls

Change scheduling for multiple

HVAC units at same time

Monitor “health” of equipment

Internet accessible

Alarming via text msg or email

Collect/trend data

Integrate to lighting control or security system

3/11/2013

1

3/11/2013 z DDC Direct Digital Control of an HVAC system z A method of monitoring and controlling

HVAC system performance by collecting, processing, and sending information using sensors, actuators, and microprocessors.

What is DDC?

z DDC is the concept or theory of HVAC system control that uses digital controls z Physically, DDC encompasses all the devices used to implement this control method: a whole group of DDC controllers/microprocessors, actuators, sensors, and other devices.

What is DDC?

2

3/11/2013

DDC - the Control

Theory input-process-output cycle z A point is ANY input or output device used to control the overall or specific performance of equipment or output devices related to the equipment.

What Is a Point?

3

AI z

DI z

AO z

DO z

Analog input - a sensor that monitors physical data, such as temperature, flow, or pressure.

Discrete input - a sensor that monitors status .

Momentary and maintained switches, ON-OFF equipment status, and digital pulses from flow and electric power meters are discrete inputs.

Analog output - a physical action of a proportional device in the controlled equipment - e.g., actuator opens air damper from 20% to 40%, other dampers, valves, inlet guide vanes, etc.

Discrete output - changes or maintains device status. Performs momentary or maintained switching for start/stop of pumps, fans, two-position dampers, and on/off control.

Four Kinds of Points

3/11/2013

Input sensors and status devices react to changes in conditions . Conditions include internal load, outside air temperature, and output actions .

Output devices act based on sensor and status device reactions .

Ex. 1:

Open cooling coil valve (output action). Supply air temperature sensor

SAT detects (input reaction) decrease in temperature.

Ex. 2:

Filters on an air handler get dirty (conditions). Air switch reacts by closing contact for “filter dirty” alarm.

DDC: Actions and Reactions

4

3/11/2013

Control Point

Identification Exercise

AI z z z z z z z Temperature

–

–

–

Thermistors

Resistance Temp. Detectors

(RTDs)

Transmitters

Pressure

Humidity

Flow (CFM, GPM)

Voltage

Current

CO2

DI z z z

Switch dry contact

(open or closed)

–

Airflow

–

–

Water

Differential pressure

High/low limit switch

(alarm or normal)

–

–

Freeze alarm

Smoke detectors

Wattmeter pulses

(pulse initiator or counter)

Sensor and Status Devices used as Input Points

(Reactions)

5

AO z z z

Damper actuators

Modulating valves

VFD

DO z Solenoid valves z z

Relays / contactors

Alarm signal

Devices used as Output Points

(Actions)

3/11/2013

Closed Loop Control is accomplished by the control signal being sent to the controlled device with constant feedback from the sensor/status device providing input to the controller.

DDC: Closed Loop Control

6

3/11/2013

Closed loop control is determined by: z Control algorithms z Configuration values z Time schedule data z Setpoint schedule data

Closed Loop

Control

•

•

•

•

•

•

•

•

Heating/cooling coil control

Humidification/dehumidification

Mixed air damper optimization

VAV fan control

VAV supply & return fan tracking

Indoor air quality

Generic PID control

Control point reset

Typical Control

Algorithms

7

•

•

•

•

•

•

•

•

•

Time of day scheduling

Discrete device controlled as analog

Discrete interlock

Discrete staging

Proportional thermostat

Primary/secondary pump control

Night free cooling

Adaptable start/stop

Permissive interlock

Typical Control

Algorithms (cont’d)

P Proportional

PI Proportional-Integral

PID

Proportional-Integral-Derivative

Algorithm Type Used by

Processor Determines

Control Strategy

3/11/2013

8

PID =

Proportional-Integral-Derivative Control z z

What it is: This type of control algorithm is based on value/amount (proportion), rate of change (integral), and error allowances (derivative). PID control calculates and sends commands for outputs based on all three types of information.

Advantages: More precise than P and PI controls,

PID wastes less energy based on more frequent feedback and quicker responses.

What Is PID Control?

3/11/2013 z What it is: Control algorithm based only on value/amount (proportion). z Disadvantages: Less precise than PID and PI control; cannot respond to error margins or time. Uses the most energy due to over- and under- outputs.

Proportional Control (P)

9

z z

What it is: Control algorithm based on value/amount

(proportion), rate of change (integral). PID uses error allowances (derivative) as well.

Advantages: More precise control and less energy used than proportional (P); minimum swings from setpoints.

Proportional-Integral Control (PI) &

(PID)

Exercise 1:

Building Direct Digital Control on a CV Air Handler

3/11/2013

10

3/11/2013

Exercise 1: Base CV

Air Handler Unit -No

Controls

Exercise 1: AHU - DDC

Control of

Start / Stop

Scheduling

11

3/11/2013

Exercise 1: AHU - Add

DDC

Damper

Exercise 1: AHU - Add DDC

Cooling Coil

Control

12

3/11/2013

Exercise 1: AHU - Add DDC Outside Air reset and Enthalpy Control

13

3/11/2013

Control Point Summary for Base CV AHU

Exercise 2:

Building Direct Digital Control on a VAV Air Handler

14

History

z z

VAV systems came into favor for mid and large size facilities in the 1960s and 1970s

–

Save energy

–

–

–

Improve comfort

Take advantage of building diversity

Cooling needed year round for true interior core zones

Sequence

–

Main AHU provides morning warm-up heat until RAT setpoint is satisfied – all zones at 100% design airflow

–

–

AHU switches to 55°F discharge air controlled cooling – zones modulate CFM to controls space temp

No AHU heat remainder of day – individual zone reheat or baseboard as needed

Zoning Systems

3/11/2013

15

Single Zone Systems

Heating/Cooling

Unit

ROOF

Heating/Cooling

Unit

Heating/Cooling

Unit

Heating/Cooling

Unit

TMT

ZONE 1 ZONE 2

TM

ZONE 3 ZONE 4

TM

Multiple Zone Systems

3/11/2013

16

3/11/2013

To Build DDC on a VAV AHU,

Start with DDC on a CV AHU...

Exercise 2: Create a VAV

AHU with Inlet Guide

* If using VFD, use two Variable Frequency Drives instead, but you will still need the same control points and HPS shown.

17

• Filter Status (FLTS)

• FreezeStat (FRZ)

• Smoke Detector (SMK)

Typical DDC Items You Can Add as Optional Items:

3/11/2013

Exercise 2: VAV AHU with DDC Filter Status

18

3/11/2013

Exercise 2: VAV AHU with DDC

FreezeStat

Exercise 2: VAV AHU with DDC Smoke

Detector

19

3/11/2013

DDC Controllers

Programmable controllers

Application

Specific controllers

Control

Point

Summary for Base

VAV AHU

Factory integrated controllers

20

3/11/2013

Types of Direct Digital Control Networks z Interface - devices and software that work as a translator between a DDC system and the humans who operate it.

z An interface is the operator’s window into a building’s operating systems and conditions.

Interfaces to DDC

21

•

User interfaces:

Allow more efficient system operation monitoring.

You can look at what’s happening on all floors from the tenth floor if DDC network is peer-to-peer.

• Allow immediate diagnosis of HVAC units and controls, including changes, without physically being in front of the unit.

• Can provide reports (e.g., historical, consumable, run times, system activity) to be used as records of building operations.

• Can provide graphical representations of the controlled system.

User Interface Benefits

3/11/2013

User Interface Types

22

3/11/2013

Hand-held Connected to a DDC Controller

Interface

Examples

PC Connected to a DDC Network

Interface

Examples

23

3/11/2013

Web Server Connected to DDC Network

Interface

Examples

Web Interfaces

z Standard web browser or WAP access z View system status z Access schedules and setpoints z z

Trending, alarming, reporting

Real time interactive graphics

24

FLOOR PLAN GRAPHICS

3/11/2013

EQUIPMENT GRAPHICS

25

EQUIPMENT GRAPHICS

3/11/2013

FLEXIBLE SCHEDULING

26

TRENDING

Internet Thermostats

z Low cost alternative to

BAS z Direct to Ethernet z No PC software – uses standard web browser z No access fees z Text/email alerts

3/11/2013

27

Internet Thermostats

3/11/2013

Internet Thermostats

28

Phone Apps for Thermostats

3/11/2013

Integration

z z z

–

Information Transfer

Add new HVAC equipment to an existing Building

Management System

Common User Interface

–

–

Building Integration

Lighting, HVAC, Security, Fire & Life Safety

Enterprise Integration-Utilities, Financial

29

Building Management Systems

HVAC

Lighting

Security

Power

Metering

Common Protocols

PT

PT

PT

MODBUS®

3/11/2013

30

Integration

Interoperability is the ability of different devices from the same or different manufacturers to function accurately together.

Standard protocol - a set of guidelines for commands, inputs, and output encoding to create a universal language for all DDC devices. When the same standard protocol is used in DDC devices, interoperability is possible.

Gateways - devices added to DDC networks to make standard protocols available and interoperability possible.

Interoperability

BACnet

Standard protocol requirements for B uilding A utomation and C ontrol net working, created by ASHRAE to ensure interoperability. BACnet uses software and a LAN interface to DDC to provide:

•

•

•

Representation of all manufacturer devices’ internal functioning in a common, network-visible way.

A common command set for device services.

Common encoding of commands, understandable by all devices and interfaces adhering to the protocol.

3/11/2013

31

Enterprise

Security Systems

Energy

MODBUS

Lighting

Fire Systems

LEGACY

Open System

Framework

CFO

XML SQL

HTTP HTML

ODBC SNMP

Facility

Management

JDBC FTP

WAP

SMTP

HVAC Systems

And More

Typical Questions

z z

Q: What part of the control system is done by the HVAC designer?

What is done by the installing contractor? Do most HVAC engineers actually do control system work or is that done by specialty contractors?

A: Depends on the project

–

–

A good designer lays out the control system as an integral part of the mechanical system, including: z Sequence of operation z Front-end/user interface details

The details of hardware, software, and cabling should be left to the contractor since every manufacturer’s system is different

– Unfortunately, most designers rely on manufacturers to write project specs, or worse, contractors to design in the field as they install

3/11/2013

32

Typical Questions

z z

Q: How does one select the type, number, and position of sensors? (i.e. measure temp in a room or in the supply duct? Where in the room or duct do the sensors go?

How many go in each room?)

A: Depends on the project

–

–

Best to measure what you want to control – usually space temp z Mount between 4 and 5 ft high, out of direct sunlight, and in the return air path z One sensor per controllable piece of equipment is best – usually one per room

Many exceptions for specialty systems and/or install cost compromises

Typical Questions

z z

Q: How does one go about determining the coefficients of a P, PI, or PID controller and tune the system once it has been installed?

A: Practice and Patience

–

–

–

–

Zero out the derivative term – HVAC equipment and building systems react too slowly for it to matter

Tune the proportional term first, then worry about integral term

Make small changes and monitor

Use a dynamic graph

3/11/2013

33

Typical Questions

z z

Q: Where can one go to get more information and training?

A:

–

–

–

–

–

Iowa Energy Center / Iowa State University z www.ddc-online.org

ASHRAE Learning Institute z http://www.ashrae.org/education/page/1809

Continental Automated Buildings Association - www.caba.org

www.automatedbuildings.com

BACnet - www.bacnet.org

Case Study – Conrad Hotel

z z z

–

352 HVAC units

311 guestrooms

Added DDC controls

–

Occupancy sensors

Entrance door & motion

3/11/2013

34

Energy Savings Estimation Tools

3/11/2013

• Programmable Thermostat

• Nicor Gas or NIPSCO Gas – $50

•

•

Peoples Gas or North Shore Gas – $80

Wisconsin Focus on Energy – $100 per RTU

• Economizer Controls

•

•

ComEd – $40 per ton

Wisconsin Focus on Energy – $250 per RTU

• CO2-based DCV

• ComEd – $0.03 per ft2

•

•

•

•

•

DCEO – $0.28 to 0.40 per ft2

Peoples Gas or North Shore Gas – double custom

NIPSCO Gas – $0.15 per ft2

Wisconsin Focus on Energy – $0.05/CFM supply

Wisconsin Focus on Energy – $350 per RTU

35

• Boiler Reset Control

• Nicor Gas – $0.50 per MBH

•

•

•

Peoples Gas or North Shore Gas – $500

NIPSCO Gas – $0.35 per MBH

Wisconsin Focus on Energy – $75/controller

• DDC Controls

•

•

ComEd – $0.20 per ft2

DCEO – $0.20 to 0.40 per ft2

• Variable Frequency Drives (VFDs)

•

•

ComEd – $60 per Hp

DCEO – $92 per Hp

•

•

NIPSCO Electric - $40 per Hp

Wisconsin Focus on Energy – $50 per Hp

• Hotel Guest Room Energy Mgmt System

• ComEd – $25 to 65 per unit

• Kitchen Exhaust Demand Control Ventilation

• ComEd – $350 per Hp

• Custom Incentives (based on annual savings )

• ComEd – $0.06 to 0.07 per kWh

•

•

•

•

Nicor Gas – $0.75 to 1.00 per therm

Peoples Gas or North Shore Gas – $1.00 per therm

DCEO – $0.12/kWh and $3.00/therm

NIPSCO – $0.09/kWh and $0.60/therm

3/11/2013

36

3/11/2013

Ryan R. Hoger,

LEED AP

37