OFMR Operations and Maintenance Manual 2012

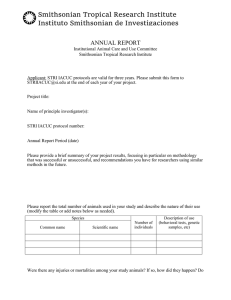

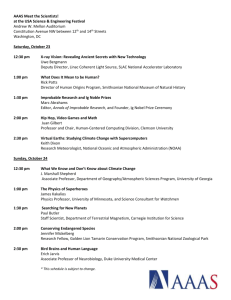

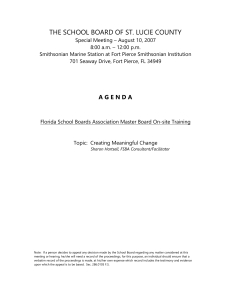

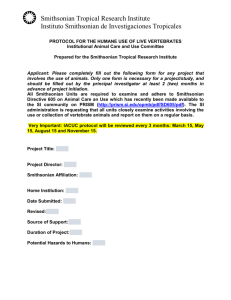

advertisement