Analysis of Financial Incentives for Early CCS Deployment October 2010

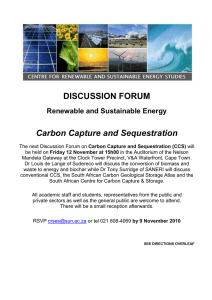

advertisement