Chapter 1. Materials for Engineering

advertisement

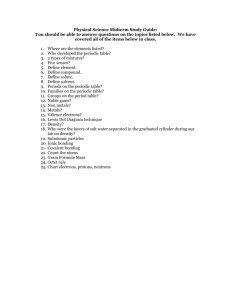

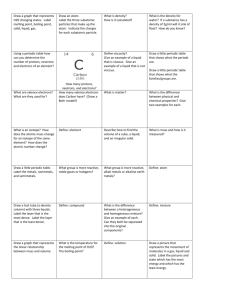

Chapter 1. Materials for Engineering • The Materials World • Materials Science and Engineering • Types of Materials – Metals – Ceramics (and Glasses) – Polymers – Composites – Semiconductors • From Structure to Properties • Processing Materials • Selecting Materials The Materials World • History – – – – Stone Age: 2.5 million years ago Pottery Age: 4000 B.C.E Copper Age: 4000 B.C.E – 3000 B.C.E. Bronze Age: 2000 B.C.E – 1000 B.C.E. • Foundation of metallurgy- Alloys of copper and tin – Iron Age: 1000 B.C.E – 1B.C.E. – Plastics Age: late 20th Century to current time – Semiconductor Age: late 20th Century to current time • Materials Types of Materials – Metals – Ceramics and Glasses • Semiconductors Simple Liquids Gases – Polymers • Composites All Materials Metals Ceramics Solids Polymers (polymeric molecules Thermoplastics Heat Forming Thermosets Heat Setting Elastomers Periodic Table • Invented by Dmitri Medeleyev in the late 1800’s • Many of the elements in the table were not discovered until long after the table was invented • All elements are in their most basic form and cannot be simplified • Table lists the atomic number and atomic mass • The atomic number is the number of protons in the nucleus or the center of the atom • The atomic mass is the sum of the masses of the protons and neutrons. Electrons weigh about 1/2000 as a proton. • Carbon (C) has atomic number 6 because there are 6 protons in the nucleus. • Periodic Chart Organization Elements are divided into two groups- metals and nonmetals – Of the 120 known elements (including synthesize), approximately 81 are metals. 92 occur naturally in the earth. • Metals have the following characteristics to varying degrees – – – – • High electrical conductivity and High thermal conductivity Luster- ability to reflext light. Ductility, maleability Loose electrons (low ionization energy) readily when they react with nonmetals Metallic character should decrease as we move across the Periodic Table and increase as we move down. Nonmetals tend to be insulators (solid, liquid, or gas) – Gain electrons in chemical reactions • • Noble gases are inert Metalloids are semiconductors Periodic Table IA IIA ….Groups… IIIA IVA VA VIA VIIA VIIIA Atm # Symbol Wgt 1 H 1.01 B Groups Lanthanides Actinides Excellent Reference: http://www-tech.mit.edu/Chemicool/ Periodic Table • Groups – I: Group 1 is also called the alkali metal group. These are strong metals that are unusually soft and very reactive toward Oxygen forming Oxides and water forming hydroxides of the metal. – II: Group 2 is called the alkaline earth metals. These metals are not as soft as Group 1 metals. They also react more mildly with Oxygen to produce oxides of the metals and only react with water at temperatures where the water is steam. – Groups 3-12 are referred to as the transition metal groups. These metals are not as predictable Periodic Table • Groups 3B- are referred to as the transition metal groups. – These metals are not as predictable because of the shielding effect of the inner electrons. As for the "shielding effect" this refers to the inner electrons found in the transition state elements and the inner transition (rare earth)elements. These electrons had a tendency to block the electrical effect of the positive nucleus upon the outer valence electrons of those atoms. This shielding effect helps to partially explain the erratic placement of the electrons in the d and f orbitals relative to the s and p orbitals. • Groups 1A-2A and 3A-8A are referred to as the representative elements • Group 7A is referred to as the halogen group • Group 8A is referred to as the Noble gas group previously known as the inert gas group. Periodic Table • The metals which tend to have their atoms losing electrons during a chemical change are roughly found to the left Group 3 • Non-metals which tend to have their atoms gaining electrons during chemical change are roughly found in Group 6A-7A with some elements in the lower parts of Groups 5A. • Metalloids which tend to have their atoms sometimes losing and sometimes gaining electrons during chemical change are generally found in Groups 4A-6A • The Noble gases really belong to their own category since their atoms tend neither to lose or gain electrons. There are only a handful of compounds involving the Noble Gases (mostly involving Xenon). Periodic Table Properties • As you proceed to the left in a period or as you proceed down within a group: – The metallic strengths increase (non-metallic strengths decrease). – The atomic radius of atoms (distance from the nucleus to the outermost occupied region) increases. Atomic radii are the distance between the outermost occupied probability region of an atom and its nucleus. – The ionization potential (energy required to remove an electron from an atom) decreases. Ionization Potential is energy required to remove electron from atom. – The electron affinity (energy released as electron is picked up by an atom) decreases. – The electronegativity (the electron attracting ability of an atom) decreases. Periodic Table Metals • Metals – Largest group in periodic table. – Ferrous and non-ferrous types – Various alloys • Steel alloys, Aluminum, Mg, Ti, Ni, Zn, Cu • Brasses, Cu, Zn – Iron alloys are the most used material in this group • Automotive • Construction – Metallic Nature • Strong and can be formed into practical shapes, • Ductile with permanent deformation • Good conductor of electricity and heat Periodic Table Ceramics and Glasses • Ceramics are – complex compounds and solutions that contain both metallic and nonmetallic elements (C, N, O, P, or S) – heated at least to incandescence during processing applications, – typically hard and brittle, – exhibit high strength and high melting points, – exhibit low thermal and electrical conductivity. – Have a crystalline structure in which the atoms are stacked in a regular, repeating pattern with a fixed distance between the atoms. – Can be made in an amorphous structure with a random pattern, like glass (silicates) • Applications – Pottery, brick, tile, glass, ovenware, magnets, refractories, cutting tools. – Furnace linings and tiles for space shuttle due to high resistance to heat. – Superconductivity applications • Types – Aluminum oxide, Magnesium oxide, silicon oxide, silicon nitride Periodic Table Polymers • Polymer materials are made up of “many” (poly) repeating “units”(mers). • Polymers are mostly based in carbon, oxygen, and hydrogen. Some have Si, F, Cl, S • Polymers are considered a bowl of spaghetti or a bag of worms in constant motion. Periodic Table Formation of Polymers • Polymers from Addition reaction – LDPE HDPE PP H H H H H H C C C C C C H H – PVC n H H PS H H H H C C C C H Cl n H n n H CH3 n Common Polymer Synthesis • Polyamides – Condensation Polymerization • Nylon 6/6 because both the acid and amine contain 6 carbon atoms NH2(CH2)6NH2 + COOH(CH2)4COOH Hexamethylene diamene Adipic acid n[NH2(CH2)6NH2 ·CO(CH2)4COOH] (heat) Nylon salt [NH(CH2)4NH · CO(CH2)4CO]n + nH2O Nylon 6,6 polymer chain Polycarbonate CH2 C CH2 OH OH + nCOCl2 O CH2 O C CH2 Bisphenol-A + Phosgene O + C n Polycarbonate + salt NaCl Thermoplastics and Thermosets • All polymers made from either condensation or addition polymerization are either – Thermoplastic, heat forming – Thermoset, heat setting • Thermoplastic bonds are covalent • Thermoset bonds are covalent and crosslinked Thermoset Chemistry Epoxy Chemistry Thermoset Polyesters • Crosslinking of thermoset polyester – Produced via condensation reaction. • The H on one monomer (alcohol) reacts with the OH on the other (acid) to form water byproduct and a new bond is formed linking the monomers. • This repeats because each of the monomers has two reactive sites. • The second site is a C=C double bond that is only active in addition reactions and is not involved in the initial reaction that forms the basic polymer. • The basic polymer is a liquid allowing it to be poured into a mold for the crosslinking reaction to occur. • Crosslinking occurs when styrene and an initiator in added to crosslink and polymerize the polyester. • The resulting structure is characterized by principle chains of polyesters that were formed by condensation polymerization and then subsequently crosslinked using addition reaction often using bridge monomer (styrene). • Analogy to this type of reaction is baking a cake. The cake batter is liquid polymer of low chain length and placed in mold (oven). As the cake heats up the liquid is converted to solid cake due to crosslinking. Demold and cools. • Composites Composite definition – A composite is a material comprised of two or more physically distinct materials with at least one material providing reinforcing properties on strength and modulus. • Natural Composites – Bone – Wood – Bamboo: Natures fiber glass due to pronounced fibrillar structure which is very apparent when fractured. – Muscle and other tissue • Engineering Composites – Reinforced concrete beams – Thermoset composites: Thermoset resins (polyurethanes, polesters, epoxies) • Glass fibers, Carbon fibers, Synthetic fibers, metalfibers, or ceramic fibers – Thermoplastic composites (polypropylene, nylon, polyester,TPU,polyimide) • Glass fibers, Carbon fibers, Synthetic fibers, metalfibers, or ceramic fibers SMC Sheet Molding Compound: Polyester Resin and chopped glass Automotive Applications of Plastics and Composites n Composite Intensive Vehicles Polyester resin and Glass Mat Preform With RTM Resin Transfer Molding 8-25 -98 M41_au 25 5 Automotive Plastics and Composites Plastic Fender Use SMC Sheet Molding Compound SMC Sheet Molding Compound Semiconductors • Semiconductors are – Neither good electrical conductors nor good electrical insulators – Able to conduct electricity intermediately – Important section of periodic table • Si, Ge, Sn from column IVA serve as a boundary between metallic and nonmetallic elements – Si and Ge are widely used semiconductors • O, to Te and Zn to Hg are used with Si and Ge to form a semi conductor from groups in columns III and V (Ga As which is used as a high temperature rectifier and a laser material) or from columns II and VI (CdS which is used as a low-cost solar cell for conversion of solar energy to electrical energy) • Some ceramics display semi-conducting behavior, e.g., ZnO which is widely used as a phosphor in color television. Periodic Table From Structure to Properties • Structure of the atoms dictates often the properties of the material – Crystalline versus amorphous structure – Al alloys are ductile, while magnesium alloys are typically brittle • Al structure follows a cubic packing arrangement and the Mg follows a hexagonal one. • In Al there are four times as many deformation modes as for the Mg structure. • Heat treatment dramatically affects the properties because it changes the structure of the metal. – Ceramics can be made opaque (Al2O3) by having a change in the microscopic-scale architecture. • The structure can be made pore free for an opaque material. Processing and Materials Selection • Processing of materials dramatically affects the properties – – – – Steel: Heat treatments provides many variations of Al Aluminum- heat treatments provides many variations of Al Plastics- quenching of PET enable clear bottles for sodas Composites- post curing improves strengths and stiffness • Materials selection – Materials are selected for applications based upon • Cost of part (piece price) – Material cost accounts for 50% to 90% of total part cost • Mechanical properties – Stiffer materials for load bearing applications (tensile modulus) – Stronger materials for impact and bending applications – Electrical and Thermal properties • Shape – Forming a material to a particular shape limits material selection • Appearance – Paintability, shininess, texture, smell, etc.