Document 15890741

http://www.mercedesbenz.com.tw/content/taiwan/mpc/mpc_taiwan_website/twng/home_mpc/passe ngercars/home/new_cars/models/m-class/w166.flash.html

Target costing techniques are important tools for controlling costs in the early stages of product development.

This article describes how Mercedes-Benz used target costing in the design and production of the M-class , a new sports utility vehicle.

在產品研發的早期階段,目標成

本法是控制成本的重要發展。

本文介紹在設計和生產M系列,

Mercedes-Benz如何使用目標成

本法,M系列是一個新的運動型

多功能車。

Mercedes' marketing research showed that customers in this market segment hold established expectations about product characteristics and price levels.

This marketing information was used to design a vehicle with the characteristics that customers wanted, at a selling price that customers would pay, and that would produce an acceptable level of profitability for investors.

Mercedes公司市場研究表明,關於產品

特色和價格水平,在這市場領域的客戶

抱有既定的期望。

這市場資訊被用來設計出特色車輛,

客戶想要願意支付的銷售價格,並為

投資者產生一個可接受的獲利水平。

Target costing systems have three major characteristics

(Cooper, 1995):

Targets for price, quality, and function are set in advance.

Major costs are identified in the design phase

.

The approach is multifunctional.

目標成本法系統有三個主要特點(Cooper,1995):

目標的價格、品質和功能是預先設置的。

主要成本都在計畫階段確定。

該方法是多功能的。

To develop the M-class, Mercedes used multifunctional teams that included product and process engineers, marketing professionals, and suppliers. The company held focus groups to help define features that potential customers expected to see in a sports utility vehicle from Mercedes.

為了開發M系列,Mercedes使用

多功能團隊,其中包括產品和製程工

程師,市場行銷專業人員和供應商。

公司所持有的重點團隊來幫助明確的

功 能 , 期 望 潛 在 客 戶 注 意 來 自

Mercedes的運動型多功能車。

Target costing was a logical cost management technique for Mercedes to use because the company was designing a completely new vehicle and concurrently constructing a new production facility. As a result, Mercedes could define a significant portion of the production costs that would be incurred before the costs were actually committed.

Mercedes使用目標成本法是一個

合理的成本管理方法,因為該公司正

在設計一種全新的車款,同時建造新

的生產設備。其結果是Mercedes可以

確定將之前發生的成本,實際上是致

力於重要的生產成本。

Successful implementation of target costing principles requires managing many interrelated components, including the following

(Ansari and Bell,1997 )

Price-led costing,

Customer orientation,

Focus on product and process design,

Cross-functional teams,

life-cycle cost reduction,

Value chain involvement ,

成功實施目標成本的原則,需要管理許多相互關聯的

組成,其中包括以下內容(Ansari and Bell,1997年)

價格主導成本計算

以客戶為導向

專注於產品和流程設計

多功能型團隊

生命週期成本的降低

價值鏈的介入

Price-led costing. In many industries, pricing has traditionally been a function of cost. Markups, or profit margins, are simply added to the estimated cost of a product to set an initial market price. If customers reject a price determined in this manner, producers have little recourse other than to reduce their margin, though they can also attempt to trim production costs.

價格主導成本計算。在很多行業,

定價一向是成本的功能。標記或利潤

空間,簡單的產品到一個初始市場價

格設置的估計成本。如果客戶拒絕以

這種方式決定價格,生產者毫無其他

辦法,減少自己的利潤,但他們也可

以嘗試削減生產成本。

Target costing practices treat selling prices and margins as uncontrollable variables, because the markets determine selling prices, and companies must earn adequate margins to remain in business over the long term. Thus, cost is the only variable that can be influenced by management.

目標成本法的做法把銷售價格

和利潤視為無法控制的變數,因為

市場決定銷售價格,和公司在長期

的繼續經營下,必須賺取足夠的利

潤。因此,成本是唯一的變數,可

受管理階層的影響。

Customer orientation. Delivering products customers want at a price they are willing to pay is a fundamental premise " of target " costing. Lean enterprises survive by gaining a series of short-term advantages over their competitors in one of three customer-oriented variables

(the survival triplet) (Cooper,1995)

以客戶為導向。提供客戶願意支

付產品的價格,是“目標”成本的一

個基本前提。精實企業的生存,獲得

一系列的短期優勢,在一個以客戶為

導向的三個變數,超過其競爭對手。

(the survival triplet)

(Cooper,1995)

Price,

Quality,

Functionality,

Ultimately consumers determine minimum acceptable standards for quality and functionality and they define a maximum acceptable market price.

價格

品質

功能

最終消費者確定可接受最低的

品質和功能及他們明確的一個最大

可接受的市場價格標準。

Short-term competitive advantage can be gained by managing the elements of the competition. For example, competitive advantage can be gained if a company can deliver comparable quality and functionality at a price significantly below that of its competitors. Similarly, a company can also gain a competitive advantage by providing greater functionality, higher quality, or both at comparable prices.

可以透過管理的競爭要素,獲得短

期的競爭優勢。例如,如果一家公司,

在價格顯著低於其競爭對手時,可以提

供同等的品質和功能,增加競爭力的優

勢。同樣,公司還可以提供更多的功能,

更高的品質,或按兩者相似價格計算,

獲得競爭優勢。

Focus on product and process design. Many production costs derive from decisions made during the design phase. Consequently, cost-reduction efforts should focus on phases before production begins. Mercedes, for example, made decisions early in the product-development process to reduce the level of value-added (or conversion) activities and costs within its planned facility.

專注於產品和流程設計。許多生

產成本來自設計階段所作出的決定。

因此,努力降低成本,應該集中於生

產階段之前的階段。例如Mercedes,

在產品開發過程前作出決定,水平降

低附加價值(或轉換)活動和在其計

劃中的設備成本。

Traditionally, purchased components have made up from 55% to 60% of unit production costs at Mercedes, which means that value-added percentages have ranged from 40% to 45%. During the product- and process-design phase for the M-class , Mercedes made the strategic decision to rely heavily on systems suppliers. As a result, the valueadded percentage in the new plant where the M-class is made is only 20% to 25% of manufacturing cost.

傳統上,從Mercedes單位生產成

本的55%至60%採購零件,這意味著

增值百分比為40%至45%不等。在M系

列產品和流程設計階段,Mercedes策

略決策嚴重依賴於系統供應商。其結

果是,其中新工廠的M系列,只有增值

百分比為20%至25%的製造成本。

Cross-functional teams. Target costing begins with customer needs. It should end with a product that meets or exceeds customer expectations. For this to happen, however, a wide variety of professional expertise is required. At Mercedes the cross-functional design team included cost planners, design engineers, systems suppliers, and marketing professionals had to coordinate their work to enhance quality and control costs.

跨功能型團隊。目標成本最終來自

於客戶的需求。在最終的產品,以滿足

或超過顧客的期望。為了做到這一點,

各 種 各 樣 的 專 業 知 識 是 必 需 的 。 在

Mercedes的跨功能型團隊包括成本規劃

師、設計工程師、系統供應商和市場行

銷專業人士,其必須協調其工作,以提

高品質和控制成本。

Life-cycle cost reduction. Target costing also encourages designers to consider costs that extend beyond the manufacturing stage. Because target costing principles are customer-oriented, design decisions should seek to minimize both manufacturing costs and the ownership costs that customers will incur.

生命週期成本的降低。目標

成本鼓勵製程工程師考慮以超出

製造階段的成本。因為目標成本

計算原則是以客戶為導向,設計

決策應設法儘量減少製造成本和

客戶會承擔的擁有成本。

For example, although the Mercedes E300 diesel has a relatively high sticker price, it is the choice of many European cab companies because its maintenance costs are low, and its life commonly exceeds 300,000 miles. Lower operation costs during the vehicle's useful life and higher resale values are examples of life cycle cost-reduction strategies affected by engineering design choices.

例如,雖然Mercedes E300柴油具

有相對較高的售價,但是是許多歐洲出

租車公司的選擇,因為它的維護成本也

較低,其壽命通常超過30萬英里。在汽

車的使用壽命和更高的轉售價值,降低

營運成本,生命週期成本削減的策略影

響工程設計選擇。

Value chain involvement. Target costing principles stress the importance of managing costs throughout the value chain.

Involving " upstream " suppliers early in development is crucial. Involving suppliers early during the design phase helped Mercedes improve quality and reduce costs. "

Downstream " input

- the involvement, for example, of the marketing and customer service departments

- is also necessary to achieve the strategic benefits of target costing.

價值鏈的介入。目標成本的原則,強

調整個價值鏈管理成本的重要性。涉及

“上游”供應商早期開發是至關重要的。

早 在 設 計 階 段 涉 及 到 供 應 商 , 說 明

Mercedes提高產品品質和降低成本。“下

游”的投入參與,例如,市場行銷和客戶

服務部門,也是有必要實現策略目標成本

的利益。

To explain how Mercedes used target costing techniques in developing the M class, the following sections discuss each of the major target costing characteristics mentioned previously. Also discussed are innovations Mercedes developed, which include various indexes that explicitly link engineering and financial concepts.

為了解釋Mercedes如何使用目

標成本開發M系列的技術,以下各

節討論前面提到的主要目標成本的

特點。還討論了Mercedes的創新開

發,其中包括各項指標明確聯繫工

程和財務概念。

Background. In the early 1990s, Mercedes struggled with problems in product development, cost efficiency, material purchasing, and adaption to changing markets. By 1993 Mercedes had experienced its worst sales slump in decades, and it lost money for the first time in its history.

Since that time, Mercedes has streamlined its core business, reduced parts and system complexity, and established simultaneous engineering programs with suppliers.

背景。在1990年代初期,Mercedes競爭

在產品開發、成本效益、材料採購和適應不

斷變化的市場問題。在1993 年Mercedes經

歷數十年來最嚴重的銷售低迷,其歷史上第

一次虧錢。

自那時起,Mercedes精簡其核心業務、

減少了零件和系統的複雜性,並建立與供應

商的同步工程計劃。

New products. In a search for additional market share, new segments, and new niches, Mercedes started developing a range of new products. The new C-class debuted in 1993, the E-class in 1995, the new sportster SLK in 1996, and both the A-class and the M-class All Activity Vehicle in 1997.

Perhaps the largest and most radical of all the new projects was the M-class.

新產品搜索更多的市場分類、切割

新市場和新的利基市場,Mercede開始

制定一系列新產品。在1993年推出的新

C 系 列 , E 系 列 於 1995 年 , 新 的

SPORTSTER SLK於1996年,A系列和M系

列所有活動車輛於1997年。也許最大的

和最根本的是所有新專案M系列。

In April 1993, Mercedes announced it would build its first passenger vehicle manufacturing facility in the United States. The decision emphasized the company's globalization strategy and desire to move closer to customers and markets. After an intensive, six-month effort to evaluate locations suitable for a new plant costing $300 million, Mercedes chose Tuscaloosa County, Alabama.

annual production at the plant is how about 65,000 vehicles, with

North American and export volumes approximately equal.

1993年4月,Mercedes宣布將在美國

建立第一客運車輛製造工廠。決定強調公

司的全球化策略和對客戶和市場靠攏的願

望。密集六個月後的努力,以評估適合耗

資3億美元的新廠房的位置,Mercedes選

擇Tuscaloosa County, Alabama。工廠的

年度生產是如何約 65,000輛,與北美出

口量大致相等。

The M-class project can justifiably be called a radical, high-stake experiment (Woodruff and Miller, 1995). Mercedes had to build a new factory in a new country and also develop a new product for a new marker segment. While Japanese manufacturing plants built outside Japan typically copy Japanese factories and models (at least at first), Mercedes simultaneously had a new work force. During the early stages of products and process development, the popular press described the Mercedes venture as a prescription for disaster because of the many variables and unknowns involved.

M系列專案有理由可以被稱為一個激進的、

高風險的實驗(Woodruff and Miller, 1995)。

Mercedes在一個新的國家必須建立一個新的

工廠,並開發新產品為新的標記部分。雖然

在日本以外的製造工廠,一般是複製日本工

廠和模型(至少一開始是如此),Mercedes同

時擁有新的工作主力。產品和流程發展的早

期階段,大眾媒體稱Mercedes企業為一個災

難處方,因為許多變數和所涉及的未知數。

The M-class moved from concept to production relatively quickly. The concept phase began in 1992, which led to a feasibility study that the board of directors approved. The project realization phase began 1993. Finally, production began in 1997. Key elements of these various phases are described next.

如M系列從概念移到生產相對

較快。概念設計階段開始於1992年,

董事會批准的可行性研究報告。專

案實現階段開始於1993年。最後,

於1997年開始生產。下面描述這些

不同階段的主要要素。

Concept phase (1992-1993). The cross-functional team at Mercedes compared the company's existing product line with various market segments in order to find opportunities to introduce new types of vehicles. The analysis revealed opportunities in the rapidly expanding market for sports utility vehicles, dominated by Jeep,

Ford , and GM.

概念階段(1992-1993年)。

Mercedes的跨功能型團隊比較,

該公司現有的產品線,在不同的細分

市場,以便找到引進新類型車輛的機

會。分析結果顯示的機會為,運動型

多功能車的市場在迅速擴大 ,Jeep,

Ford , and GM佔主導地位。

The team conducted market research to estimate potential sales opportunities worldwide for a high-end sports utility vehicle having the characteristics of a Mercedes-Benz. A rough cost estimate was developed that included materials, labor, overhead, and one-time development and project costs. Then cash flows were projected and analyzed over a 10year period. Net present value (NPV) analysis was used to acquire approval of the project from the board of directors. Because of the capital-intensive nature of the automobile manufacturing industry, estimates of production volume are critical factors in the NPV calculation.

團 隊 進 行 市 場 調 查 研 究 , 以 估 計 全 球

Mercedes-Benz運動型多功能車的特點,潛在

高消費階層的銷售機會。一個粗略的成本估

算的開發,包括材料、勞動、開銷和一次性

開發的項目成本。現金流量進行了預測和分

析,超過10年的時間。淨現值 (NPV) 分析被

用來獲取該專案從董事會的核准專案。由於

汽車製造業的資本密集性質,淨現值計算估

計生產量的關鍵因素。

Risks and opportunities. The sensitivity of the NPV calculation was analyzed by simulating various " what-if

"scenarios involving different risks and opportunities. The risk factors that were tested included fluctuations in monetary exchange rate, different sales levels due to consumer substitution of M-class vehicles for other Mercedes products, and product and manufacturing costs that differed from projections.

風險和機會。NPV 的計算的敏

感性分析通過模擬各種“假設”方

案涉及不同的風險和機會。風險因

素進行了測試:包括貨幣匯率的波

動,不同的銷售水平,由於消費者

替代Mercedes M系列的其他產品,

從不同的產品和製造成本預測。

Based on the economic feasibility study of the concept phase, the board approved the project. The search for manufacturing locations included sites in Germany, other

European countries, and the United States. Partly because of

Mercedes globalization strategy, the decisive factor in placing the plant in the United States was the desire to be close to the biggest market for sports utility vehicles.

基於經濟可行性研究報告的概念

階段,董事會核准的專案。製造地點

搜索包括在德國、 其他歐洲國家和

美 國 的 網 站 。 部 分 原 因 是 因 為

Mercedes的全球化策略,將在美國工

廠的決定性因素,是希望接近運動型

多功能車的最大市場。

project realization phase (1993-1996). The target costing process requires broad, cross-functional activities to acquire market information necessary to develop a new vehicle. Mercedes used customer focus groups to obtain this information. The company held regular customer clinics to explain the new vehicle concept and to view the prototype.

如專案實現階段 (1993-1996 年)。

目標成本計算過程要求廣泛、多功能型

部門的活動,以獲得必要開發新車的市

場訊息。Mercedes客戶焦點組用於獲取

此資訊。公司定期舉行客戶講授,解釋

及查看新車概念的雛形。

These clinics elicited important information about how the proposed vehicle would be received by potential customers and the press. Customers were asked to rank the importance of various characteristics including safety, comfort, economy, and styling.

Engineers organized in function groups designed systems to deliver these essential characteristics.

這些講授引起了建議,車輛如何

受到潛在客戶和媒體新的重要資訊。

客戶要求的各種特性,包括安全性、

舒適性、經濟性和造型的排名的重要

性。工程師組織功能團體設計的系統

中,提供這些基本特性。

Furthermore, Mercedes would not lower its internal standards for components, even if initial customer expectations were lower than the Mercedes standard. For example, many automotive expert believe the handling of Mercedes products results from manufacturing a world-class chassis. Thus, each new class within the Mercedes line must meet strict standards for handling, even though these standards may actually exceed customer expectations for some classes.

此外,Mercedes也不會降低其內部

的標準要素,即使最初客戶的期望低於

Mercedes的標準。例如,許多汽車專家

認為Mercedes的產品處理製造世界一流

的主機殼產品結果。因此,Mercedes每

一個新系列,必須符合嚴格的標準進行

處理,儘管這些標準可能實際上超過了

一般客戶的期望。

Mercedes did not use target costing to produce the lowest-priced vehicle in an automotive class.

Rather, the company's strategic objective was to deliver products that were slightly more expensive than competitive models but with a greater perceived value on the part of the customer.

Mercedes沒有使用目標成

本,來生產汽車系列中價格最

低的汽車。相反,該公司的策

略目標是,提供的產品比具競

爭力的車型昂貴,但對部分客

戶具有更大的認知價值。

Goal-oriented approach. Another difference between

Mercedes' and other companies' use of target costing lies in the goal-oriented approach to achieving target cost. Cooper cites examples of Japanese companies that strive in a singleminded effort to achieve a static target cost. In contrast, the

M-class (and M-class target cost) remained alive throughout the product realization phase because of changing dynamics.

以目標為導向的方法 。Mercedes

公司和其他公司的目標成本之間的另

一個區別在於,以目標為導向的方法

來實現目標成本。Cooper舉例的日本

公司,一心一意地在努力實現靜態目

標成本。相比之下,M系列(M系列目

標成本)現況仍然持續改變在整個產

品實現階段。

Mercedes found it beneficial to place the design and testing team members in close physical proximity to other functions within the project to promote fast communication and decision making. In this way the company was able to respond quickly to changing conditions. For example, while the vehicle was under development, the market moved toward the luxury end of the spectrum. Crash test results were also incorporated into the evolving M-class design.

Mercedes發現其有利於將設計和

測試團隊成員,在項目中的其他功能,

自然而然接近以促進快速的溝通和決

策等功能。透過這種方式,公司能夠

快速回應不斷改變的條件。例如,雖

然在正在開發的汽車,市場移向奢侈

品極端的情況。碰撞測試結果也納入

不斷變化的M系列的設計。

In addition, Mercedes developed new technical features such as side airbags. ( The decision to include this new feature on all Mercedes lines was made at the corporate level because experience has shown that customers' reactions to a vehicle class can affect the entire brand.)

As demonstrated above, Mercedes recognized the importance of flexibility in setting and achieving target costs.

此外,Mercedes開發了新的技術

功能,如乘客側安全氣囊。(包括所有

的Mercedes這項新功能,因為經驗顯

示客戶對汽車系列的反應會影響整個

品牌。)

正如上文所述,Mercedes 明確於

彈性制定和實現目標成本的重要性。

Production phase 1997-present. The M-class project was monitored by annual updates of the net present value(NPV) analysis. In addition, a three-year plan (including income statements) was prepared annually and reported to the headquarters in Germany. Monthly departmental meetings were held to discuss actual cost performance compared with standards developed during the cost estimation process. Thus, the accounting system served as a control mechanism to ensure actual production costs conformed to target (or standard) costs.

1997年至今生產階段。 M系列專案每

年分析監測更新的淨現值(NPV)。此外,

三年的計劃(包括損益表)每年編寫並向

在德國的總部報告。每月舉行部門會議來

討論實際成本與標準制定過程中的成本估

算過程。因此,會計制度扮演控制機制,

以確保符合成本目標(或標準)的實際生

產成本。

The target costing process was led by cost planners who were engineers, not accountants. Because the cost planners were engineers with manufacturing and design experience, they could make reasonable estimates of costs that suppliers would incur in providing various systems. Also, Mercedes already owned much of the tooling , such as dies to form sheet metal, used by suppliers to produce components. Tooling costs are a substantial part of the one-time costs in the project phase.

目標成本法過程中領導成本規劃為工程

師而不是會計師。因為成本規劃具有製造和

設計經驗的工程師,其可以對供應商提供各

種系統所產生的成本做出合理的估計。此外,

Mercedes已經擁有了很多的器具,如由薄金

屬板做的模具,是利用供應商來生產零件。

模具成本在計劃階段的一次性成本中佔相當

重要的部份。

Mercedes divided the vehicle into function groups that included doors, sidewall and roof, electrical system, bumpers, powertrain, seats, heating system, cockpit, and front end. As shown in Exhibit 1, the process of achieving target cost for the M-class began with an estimate of the existing cost for each function group. Next, components of each function group were identified with their associated costs .

Mercedes劃分車子是以功能群

組,包括門、輪胎壁和車頂、電氣系

統、保險槓、動力傳動系統、座椅、

暖氣系統、駕駛座艙和前蓋。圖1所示,

達到M系列(運動型多功能車)目標成本

的過程中, 開始估計每個功能群組現

有的成本,然後,確定每個功能群組

零件的相關費用。

Team members set cost reduction targets by comparing the estimated existing cost with the target cost for each function group. Finally, cost reduction targets were established for each component. As part of the competitive benchmarking process,

Mercedes purchased and disassembled competitors' vehicles to help understand costs and manufacturing processes within the competitor's manufacturing plant.

團隊成員設定了降低成本的目標,

透過比較每個功能群組中所估計現有成

本與目標成本。最後,降低成本的目標

建立在每個零件。如同經由競爭的標桿

分析法過程的一部份,Mercedes購買和

拆卸競爭對手的車輛以幫助了解競爭對

手製造工廠內部的成本和製造過程。

A modular construction process that relied on high-valueadded systems suppliers was used to produce the M-class.

Advantages of this process include higher quality, shorter development provide entire systems rather than individual parts or components. For example, the entire cockpit was purchased as a unit from an external vendor.

基準的製造過程中依靠高附加價

值系統的供應商用於生產M系列(運動

型多功能車)。這過程的優勢包括高

品質,縮短了開發提供完整的系統而

不是個別的零件或組件。例如,整個

駕駛座艙為一套裝置是從外部供應商

購買而來的。

Systems suppliers were part of the development process from the beginning of the project. Approximately 70 suppliers worked with teams from finance and controlling, engineering, purchasing, marketing, sales, logistics, and quality control to ensure the delivery of systems that meet expectations. Mercedes expected suppliers to meet established cost targets. To enhance function group effectiveness, suppliers were brought into the discussion at an early stage in the process.

系統供應商從該計劃開始發展過程

中的一部分。大概有70個供應商的工作

團隊從財務和控制、工程、採購、行銷、

銷售、物流和品質控制,以確保交付的

系統符合所預期的。Mercedes預計的供

應商以符合既定的成本目標。為了提高

功能群組的有效性,供應商被納入討論

是處於初期階段的過程中

Index development to support target costing.

During the concept development phase, Mercedes team members used various indexes to help determine critical performance, design , and cost relationships for the Mclass. The purpose of the indexes is to ensure that resources are applied in the most effective manner.

指標發展以支持目標成本。

在概念發展階段,Mercedes團

隊成員利用各項指標以幫助決

定運動型多功能車關鍵的性能、

設計和成本之間的關係。指標

的目的是確保資源被最具效益

的方式應用。

An importance index is created by to conceptually linking the contribution of each major function group to an attribute desired by a customer. In the final stage of analysis, the value of each function group is compared with its cost. Thus, engineers can assess cost/benefit relationships during the design phase.

一個重要的指標是建立在概念

上連結每個顧客所期望的主要功能

群組特性。在分析的最後階段,每

個功能群組的價值與其成本進行比

較。因此,在設計階段工程師可以

評估成本/利益關係。

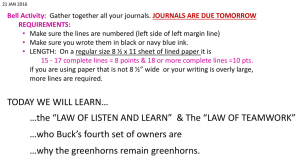

Exhibit 1. function groups of the mercercedes-BENZ M-

CLASS sport utility vehicle

圖1. 功能群組為

中華賓士、運動型多功能車

Function

Group: Chassis

Component 1

Component 2

Component 3

Component 4

Component 5

Component 6

Influence Factors

Materials

Labor

Overhead

Tooling,

Development,

Marketing, and Sales costs;

Startup and

Project Costs

Function

Group :Chassis

Component 1

Component 2

Component 3

Component 4

Component 5

Component 6

功能群組:底盤

組件1

組件2

組件3

組件4

組件5

組件6

影響因素

物料

人工

製造費用

工具

發展

行銷和銷售成本

起動和

計劃成本

功能群組:底盤

組件1

組件2

組件3

組件4

組件5

組件6

Exhibits 2-6 illustrate the calculations used to quantify various aspects of the target costing process. (All numbers have been altered for proprietary reasons; however, the tables illustrate the actual process used in the development of the M-class.) To construct the indexes, various forms of information were gathered from customers, suppliers, and the M-class design team.

圖2-6說明計算用來量化各個

觀點的目標成本過程(全部的數字

已經改變所有的原因;然而,下表

說明實際過程中使用正在發展的Mclass)。指標的概念,各種形式的

訊息收集來自於顧客、供應商和Mclass設計團隊。

Though much greater, Exhibit 2 illustrates the calculations used to quantify customer responses to the Mclass concept. For example, values shown in the importance column of Exhibit 2 resulted from asking a sample of potential customers, whether they consider each category important when contemplating the purchase of a new

Mercedes product. Individuals could respond affirmatively to all categories that applied.

表2說明了以顧客反應來量化

M-class的概念。例如,表2中的重

要性列中顯示的值產生潛在客戶要

求樣品,是否與他們認為當考慮每

個類別以購買一輛新的Mercedes產

品一樣重要。個人可以肯定的回答

是適用於所有類別的。

Exhibit 2. relative importance ranking by category

表2. 按類別劃分

相對重要性的排序

Category

Safety

Comfort

Economy

Styling

Total

類別

安全

舒適

經濟

款式

合計

Importance

45

30

5

15

95

重要性

45

30

5

15

95

Relative Percentage

47

32

5

16

100

相對百分比

47

32

5

16

100

Target costs for functions. To gain a better understanding of the various sources of costs, function groups were identified together with their target cost estimates. Exhibit

3 shows the function groups, the target cost for each, and what percentage of the total cost each represents. The target cost percentage is used in the calculation of a target cost index.

目標成本的功能。為了更好

地了解各種材料成本,功能群組

確定了目標成本的估計。表3顯

示功能群組,各種目標成本和各

種代表總成本的比例。目標成本

百分比的計算是使用目標成本指

標。

Exhibit 3. target cost and percentage by function group

表3. 功能群組的

目標成本和百分比

Function Group

Chassis

Transmission

Air conditioner

Electrical system

Other function groups

Total

Target Cost

$x,xxx

$x,xxx

$x,xxx

$x,xxx

$x,xxx

$xx,xxx

功能組

底盤

變速器

冷氣機

電氣系統

其他功能組

合計

目標成本

$x,xxx

$x,xxx

$x,xxx

$x,xxx

$x,xxx

$xx,xxx

Percentage of

Total

25

20

8

15

32

100

佔總額的百分比

25

20

8

15

32

100

Exhibit 4 summarizes how each function group contributes to the consumer requirements identified in

Exhibit 2. The rows explain the relative importance of each function group to satisfying each category defined by customers. An interesting aspect of this table is that it makes explicit the link between consumer preferences and engineering components.

表4總結了每個功能群組如何有

助於確定表2中顧客的需求。解釋每

功能群組相對重要性以符合為顧客

定義的每個類別。此表中令人感興

趣的方面是,它明確連結消費者的

喜好和工程零件。

Exhibit 4. function group contribution to customer requirements

表4. 功能群組顧客要求

進行的貢獻度

Category-Function

Group

Chassis

Transmission

Air conditioner

Electrical system

Other function groups

Total

Safety

60%

20

5

15

100%

Comfort

20%

30

20

5

25

100%

Economy

5%

30

25

40

100%

類別-功能群組 安全 舒適

底盤

變速器

冷氣機

電氣系統

其他功能群組

合計

60%

20

5

15

100%

20%

30

20

5

25

100%

經濟

5%

30

25

40

100%

Styling

5%

5

90

100%

款式

5%

5

90

100%

For example, a large proportion of potential customers identified safety as the most important characteristic of the M-class; some function groups contributed more to safety than others. Mercedes engineers determined that chassis quality was an important element of safety (60% of the total function group contribution in this example).

例如,M系列的潛在客戶確定

安全作為最重要的特性為相當大的

比例;功能群組提供比其他的更為

安全。Mercedes 工程師確定該底

盤品質安全是最重要的因素(總功

能群組的貢獻在此例子中為60%)。

Exhibit 5 combines the category weighting percentages from Exhibit 2 with the function group contribution from Exhibit 4. The key point is to understand which function groups contribute the most

(least) to important (less important) consumer categories.

The result is an importance index that measures the relative importance of each function group across all categories.

表5結合了表2之類別的權重百

分比及表4之功能群組貢獻度。其關

鍵點是要了解哪些功能群組作出貢

獻最大(最小)及重要(不重要)的顧

客類別。其結果是重要性指標,衡

量每個功能群組在各類別的相對重

要性。

For example, potential customers weighted the categories of safety, comfort, economy, and styling as .47, .32 , .05 ,and .16, respectively. The importance index for the chassis is calculated by multiplying each row value by its corresponding category value and summing the results:

例如,潛在顧客類別為安全性、舒

適 性 、 經 濟 性 和 款 式 , 其 加 權 分 別 為

0.47、0.32、0.05、0.16。底盤的重要

性指標的計算方法為每個值乘以其對應

的類別值和總和的結果:

(0.47 × 0.60 ) + ( 0.32 × 0.20 ) + ( 0.05 × 0.05 ) +

( 0.16

× 0.05 ) = 0.36

Exhibit 5. importance of various function groups

表5. 各種功能群組的重要性

Category-Function Group Safety Comfort Economy Styling Importance

Chassis

Group

Transmission

Air conditioner

Electrical system

Other function groups

Total

.47

.60

.20

.05

.15

1.00

.32

.20

.30

.20

.05

.25

1.00

.05

.05

.30

.25

.40

1.00

.16

.05

.05

.90

1.00

Index

.36

.21

.07

.05

.31

類別-功能群組 安全性 舒適性 經濟性 款式 重要性

組

底盤

變速器

冷氣機

電氣系統

其他功能群組

合計

.47

.60

.20

.05

.15

1.00

.32

.20

.30

.20

.05

.25

1.00

.05

.05

.30

.25

.40

1.00

.16

.05

.05

.90

1.00

指標

.36

.21

.07

.05

.31

As shown in Exhibit 6, the target cost index is calculated by dividing the importance index by the target cost percentage by function group. Managers at Mercedes used indexes such as these during the concept design phase to understand the relationship of the importance of a function group to the target cost of a function group.

如表6所示,目標成本指標的

計算方法是將重要性指標劃分為目

標 成 本 百 分 比 與 功 能 群 組 。

Mercedes的管理人員使用的指標,

如在概念設計階段了解功能群組的

重要性與功能群組的目標成本之間

的關係。

Exhibit 6. target cost index

表6.目標成本指標

Index-Function Group

Chassis

Transmission

Air conditioner

Electrical system

Other function groups

Total

(A)

Importance Index

.36

.21

.07

.05

.31

(B)

% of Target

Cost

.25

.20

.08

.15

.32

1.00

(C)A/B

Target Cost Index

1.44

1.05

.87

.33

.97

指標-功能群組

底盤

變速器

冷氣機

電氣系統

其他功能群組

合計

(A)(表五)

重要性指標

.36

.21

.07

.05

.31

(B)(表三)

目標成本%

.25

.20

.08

.15

.32

1.00

(C)A/B

目標成本指標

1.44

1.05

.87

.33

.97

Choices made during the project realization phase were largely irreversible during the production phase because approximately 80% of the production cost of the M-class represented materials and systems provided by external suppliers. Thus, opportunities for cost reduction, known as value engineering, are best identified and managed during the early stages of product development.

在計劃實施階段做出的選擇

在很大程度上是不可重置的,在

生產階段因為 M系列代表物料和

系統生產成本約80%由外部供應商

提供的。因此,機會成本的降低

稱為價值工程,最好能在早期管

理就能確定產品的研發階段。

Having established a target cost index, value engineering techniques may be applied to align target cost and perceived value. As defined by Cooper (1995), value engineering is the systematic, interdisciplinary examination of factors affecting cost to devise a means of achieving cost, quality, and functionality at the target cost.

建立了目標成本指標,價

值工程技術可應用於目標成本

和 知 覺 價 值 。 Cooper(1995) 定

義價值工程是系統的、各學科

間的查驗,而影響成本的因素

是目標成本的實現成本、品質

和功能性是一種策劃的手段。

Many value-engineering techniques are available. For example, purchasing, disassembling, and analyzing competitors' products provide insights into manufacturing processes and costs. This technique often is used as part of a competitive benchmarking program. Redesigning production processes and key components involves the cross-functional analysis of each component within a function group.

許多價值工程技術是可利用的。

例如,購買、拆卸和分析競爭對手

的產品提供深入了解其製造過程和

成本。這種技術經常被拿來作為具

競爭力的標桿分析法的一部分。重

新設計製程和主要零件,包含跨部

門的分析各功能群組中的零件。

Cooper describes how camera manufacturers may substitute a plastic lens to reduce costs when designing a new product. Supplier involvement early in the design phase can create opportunities for cost reduction, such as recycling reusable materials or adjusting where feasible.

Cooper介紹相機製造商在設

計新產品時可能會用塑膠的鏡片

替代以降低成本。供應商在早期

的設計階段參與,創造良機為降

低成本,如回收可再利用的物料

或在可行的情況下調整其範圍。

As The Mercedes organization produced an entirely new vehicle from concept to production in four years, on time, and within budget. Mercedes launched the M-class in September

1997 in the United States market; the export market launch occurred in March 1998. The production facility originally constructed to produce 65,000 M-class vehicles annually is currently being expanded to permit annual production of

80,000 vehicles.

Mercedes組織產生了一台全新的車輛

從概念到生產共4年的時間,並在預

算範圍內。Mercedes在1997年9月在

美國市場推出 M系列;在1998年3月

在出口市場推出。該生產設施起初製

造每年產生65,000輛 M系列,目前正

在擴大,讓每年能生產80,000輛。

The M-class project used a streamlined management structure in order to facilitate efficient and rapid development. Target costing proved to be a key management element in the success of this venture.

M 系列的計劃使用精簡的管

理架構,使其更容易達到高效率

和快速發展。證明該公司關鍵成

功管理的因素為目標成本法。

8.2 a

What are the six critical components of a target costing system ?

目標成本系統的重要組成部分是什麼?

8.2 b

Was the M-class project a risky one for Mercedes

Benz? Explain.

Mercedes Benz

其M系列計劃的風險為何?請解釋

8.2 a

價格主導成本計算

以客戶為導向

專注於產品和流程設計

跨功能型團隊

生命週期成本的降低

價值鏈的介入

8.2 b

在一個新的國家必須建立一個新的

工廠,並開發新產品為新的標記部

分。雖然在日本以外的製造工廠,

一般是複製日本工廠和模型(至少一

開始是如此),Mercedes同時擁有新

的工作主力。產品和流程發展的早

期階段,大眾媒體稱Mercedes企業

為一個災難處方,因為許多變數和

所涉及的未知數。