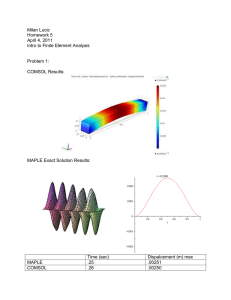

The stress concentration factor was obtained using a finite element... attached). The model was solved for values of the...

advertisement

The stress concentration factor was obtained using a finite element model built in COMSOL (file is attached). The model was solved for values of the major axis, a, of 0.01, 0.02, 0.05, and 0.1. The stress concentration factor was calculated using Equation 1. The stress concentration factors for each a/b ratio are shown in Table 1.1. σ 𝑆 = σ max (1) nom The stress concentration factor was then obtained for the same a/b ratios using a Formula given in Roark’s Formulas for Stress and Strain (Maple file is attached). It is evident that the percent error in the finite element solution increases as the ellipse aspect ratio increases. a/b 1 2 5 10 S_exact 2.864 4.514 8.536 13.178 S_numeric 2.67 4.48 10.2 22.4 % Err 6.773743 0.753212 19.49391 69.98027 Using the data from the first sheet, 𝐶 = 𝜎𝐹 ∙ √𝑎 = 480𝑀𝑃𝑎 ∙ √0.02𝑚 = 67.88 Therefore, 𝜎𝐹 = 67.88 √0.05𝑚 = 303.58𝑀𝑃𝑎 The Paris equation can be integrated via separation of variables, which results in: 14.15 = 𝐶(∆𝜎)3 (𝜋)3/2 𝑁𝑓 If the initial crack size is reduced to 0.001m, the Paris equation yields: 40.88 = 𝐶(∆𝜎)3 (𝜋)3/2 𝑁𝑓 ′ Since the unknown variables are all constants, other than 𝑁𝑓 , the increase in the number of cycles to failure is 40.88 = 2.89 14.15