T S W

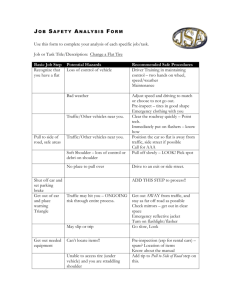

advertisement

TRIBOLOGICAL SYSTEM OF TIRE WEAR

YIN-YU CHEN

MANE6960 – FRICTION WEAR AND LUBRICATION OF MATERIALS

PROFESSOR ERNESTO GUTIERREZ-MIRAVETE

MAY 17, 2015

Page |2

ABSTRACT:

This report details a critical literature review on the tribological system of tire wear. A tire must

transmit forces from the car to the road during driving, provide a firm grip on the road, and

absorb unevenness of the road and provide a comfortable journey. A tire must perform all these

functions at a low cost to the consumer while providing a sufficiently long life, as today's tires

deliver more miles and years of service than ever before.

The tribological system of tire wear may be broken up into the subtopics of wear mechanisms

specific to the tire and the tire wear model. Wear mechanisms specific to the tire include

adhesive wear, abrasive wear, erosive wear, aging, fatigue and excessive wear, such as flat spots

and cupping. Starting with the Archard wear theory, tire wear models have grown more complex

and accurate, evolving into Pacejka’s tire models which have become today’s standards in tire

and vehicle dynamics. Future research may be done on the accuracy of the latest tire models

(Pacejka) to estimate the tire-road friction during steady-state longitudinal and corner maneuvers.

Page |3

TABLE OF CONTENTS:

Title Page ..................................................................................................................................................... 1

Abstract........................................................................................................................................................ 2

Table of Contents ........................................................................................................................................ 3

Introduction ................................................................................................................................................. 4

Discussion .................................................................................................................................................... 5

Tire Wear Mechanisms ................................................................................................................. 6

Tire Wear Models .......................................................................................................................... 8

Conclusion ................................................................................................................................................. 12

References .................................................................................................................................................. 14

Page |4

INTRODUCTION:

The definition of a tire is a protective cover to contain compressed air in a toroidal chamber that

is typically attached to a rim or wheel, made of steel or an aluminum alloy, of an automobile.

The tire, with cutaway features illustrated in Figure 1 below, must perform the following

functions:[1]

Figure 1: Tire Features

1. Transmit forces from the car to the road during driving.

a. The forces must be transmitted in a way that allows for both wear and fatigue of

the tire to be within acceptable levels. This is achieved by ensuring a larger

contact area between the tire and pavement, which results in a lower contact

pressure.

b. In addition to the weight of the automobile and the passengers and cargo

contained within it, contributors to the forces that must be transmitted include

those required to accelerate, decelerate and steer the vehicle.

2. Provide a firm grip on the road.

a. By selecting an appropriately vulcanized rubber to provide a large coefficient of

sliding friction, the tire will provide a firm grip on the road on all variability of

Page |5

road conditions.

This may include dry, wet and sometimes contaminated

conditions (such as salt during the winter or accidental oil spillage).

i. A large coefficient of sliding friction is conflicting with the demand of

tires to have low values of rolling friction and hysteresis loss in order to

increase fuel economy.

b. Firm grip on the road under all road conditions makes tires a critical component

on the automobile.

i. Approximately 14% of all fatal accidents occur when roads are wet and

grip is lost, which is only about 3% of the driving time.[2]

3. Absorb unevenness of the road and provide a comfortable journey.

a. The quality of the ride and noise produced by the slip in the contact area is

determined by the roughness and texture characteristics of the tire.

The tire must perform all these functions at a low cost to the consumer while providing a

sufficiently long life, as today's tires deliver more miles and years of service than ever before.[3]

In the 1970s, a typical bias ply tire lasted less than 20,000 miles and was only expected to be in

service for about two years. In the 1980s, early radial ply tires offered a tread wear expectancy

of about 40,000 miles with an expected service life of four years. Presently, many long-life

radial tires extend tread wear to about 60,000 miles with an expected service life of four or more

years of service. While American driving conditions in the past resulted in tire treads wearing

out before the rest of the tire aged, this may not always be true of today's even longer lasting tires

that are approach 80,000 miles of tread wear as tire technology progresses. For example,

Chrysler, Ford Motor Company and General Motors are recommending that tires installed as

Original Equipment be replaced after six years of service.

DISCUSSION:

The tribological system of tire wear may be broken up into the subtopics of wear mechanisms

specific to the tire and the tire wear model.

Page |6

TIRE WEAR MECHANISMS

The discipline of tribology has focused on the complex nature of wear and commonly includes

the wear mechanisms of adhesive wear, abrasive wear, surface fatigue, fretting wear and erosive

wear.[4] Tire wear has various causes, with which the complete process may be divided into

several of the aforementioned wear mechanisms:[5]

1. Adhesive wear: The mechanism of adhesive wear on a tire is a local phenomenon, taking

place on small spots where the contact between the tire and road is very intense. The

rubber from the tire welds to the road, resulting in a temporary adhesive force that is

broken quickly due to movement of the tire, leaving particles of rubber material on the

road. Factors of influence to the mechanism of adhesive wear for a tire include:

a. Differences in the adhesion level of the rubber. Hardness of the tire rubber

composition, where a harder rubber has a less intense adhesion with the road vice

a softer rubber having a more intense adhesion with the road.

b. Differences in the resistance to tear of the rubber. Harder rubber has a higher

tensile strength which reduces the loss of material while breaking the temporary

adhesive bond between the tire and road.

c. The roughness of the road surface and the ability of the rubber of the tire to

deform and follow the roughness. A softer rubber and tread will bring a higher

percentage of tread in contact with the road. This results in a more intense

contact, which increases tire wear.

2. Abrasive wear: The mechanism of abrasive wear on a tire results from the road surface

and particles on the road which are cutting and grinding rubber material from the tire. A

coarse road surface increases this mechanism of tire wear. There is significant difference

in wear of a tire used on a road polished by use vice a new road surface where the road

surface irregularities are still sharp and have not been worn down. Abrasive wear also

increases strongly with the variable of slip, which defines the amount of energy put into

the contact area. Not only is slip considered proportional to the abrasion loss at a given

temperature, it also increases the temperature.

A higher temperature will increase

abrasive wear since the rubber material becomes softer.

Page |7

3. Erosive wear: The mechanism of erosive wear on a tire results from cutting and grinding

of particles in a liquid stream against the tire. Erosive wear is intensified by the presence

of water, sand and other particles on the road. Harder rubber and tread material will

better withstand this wear mechanism.

4. Aging: The mechanism of aging on a tire is a result of high temperatures, UV radiation,

and deterioration. Aging as a result of high temperature occurs above 150oC, which may

be reached at very high speeds or excessive slip. Aging as a result of UV radiation only

occurs on the outer surface of the tire. Oxidation of the rubber may happen at the outer

surface of the tire, but may also occur inside the tire when filled with air. However, the

inner layers of tire are typically designed with good resistance to oxidation. Deterioration

of the rubber material is cause by chemicals, which hardly occurs with normal tire use on

an automobile.

5. Fatigue: The mechanism of fatigue on a tire is a result of deformation and microscopic

cracks which may originate in the rubber material of the tread.

Due to repeated

deformation of the tire at these areas, these cracks will grow which eventually leads to

loss of material (tire wear). This wear mechanism is responsible for the major part of

wear on an automotive tire, which is heavily affected by the raw material properties of

the tread surface and construction of the tire.

The stiffer the tire, the lower the

deformation results, which in turn limits fatigue. The effect of this wear mechanism may

also be reduced by higher tire pressure, which decreases the deformation of the tire, and

therefore fatigue.

6. Excessive wear: The mechanism of excessive wear on a tire may result from flat spots

and cupping.

a. Flat spots of the tire may result in complete locking of the wheel, which occurs

during strong braking, especially on cars without an Anti-lock Braking System

(ABS). During full locking, there is very high wear which will only occur on one

spot, which results in a flat spot on the tire. This flat spot results in an extra

vibration and noise during driving, decreasing both the comfort and traction of the

vehicle. Following occurrences of full locking will likely happen in the same

spot, since there is reduced grip and un-roundness of the tire at this spot. If this

full locking occurs for a long enough duration, the complete tread may be worn

Page |8

away, reaching the carcass of the tire, resulting in the necessity of tire

replacement. Due to ABS becoming standard on new vehicles, this type of wear

is no longer as common.

b. Cupping is a term used to cover irregular wear patterns, which is the phenomenon

of various causes such as worn shock absorbers, worn suspension bushings, loose

or worn wheel bearings, or a faulty alignment. This type of wear is heavily

dependent on the tire and type of vehicle. Tires that are stiff, wide or low profile

have a higher than average tendency for cupping. These factors cause for the

carcass to make the tread bounce over the road as opposed to continuously

following it. Cupping is also most common in rear tires due to the lower load of

the rear axle on most vehicles. In addition, modern vehicles with complex multilink rear axles have a large amount of joints, which increases the tendency for

cupping. Visual examples of cupping are included in Figure 2 below:[6]

Figure 2: Visual Examples and Common Causes of Cupping Tire Wear

TIRE WEAR MODELS

The Archard wear theory is the simplest model used to describe sliding wear, which is based on

the theory of asperity contact. The equation of Archard wear theory, Equation 1 below, relates

Page |9

the volume of material removed due to wear (W) to the normal contact force (FN), sliding

distance (L), material hardness (H), and a material-related wear coefficient (K):[7]

𝑊=

𝐾𝐹𝑁 𝐿

𝐻

Eq. 1

From the relation in Equation 2, where P is the normal pressure and A is the contact area of the

tire, Equation 3 may be obtained.

𝐹𝑁 = 𝑃𝐴

𝑊=

𝐾𝑃𝐴𝐿

𝐻

Eq. 2

Eq. 3

In the process of tire rolling, the slip distance is shown in Equation 4, where 𝛾̇ is the slip ratio

and t is the variable of time. Therefore, the ratio of volume wear may be represented by

Equation 5. An illustration of this steady rolling tire model may be found in Figure 3 below:

𝐿 = 𝛾̇ 𝑡

Eq. 4

𝐾𝑃𝐴𝛾̇

𝑊̇ = 𝐻

Eq. 5

Figure 3: Steady Rolling Tire Model

Another simple model of tire wear which takes into account frictional work was proposed by

A.G. Veith in 1985, as presented in Equation 6 below:[5]

𝑅𝑊 = 𝐴 ∗ 𝐸𝐹

Eq. 6

P a g e | 10

Where RW is the rate of wear (amount of rubber lost from a unit surface area per tire revolution),

A is the abradability (rubber lost per unit area, per unit frictional work under specified surface

conditions) and EF is the frictional work per unit area per revolution. However, the abradability,

A, and frictional work, EF, are not constants but a function of many variables, as presented in

Figure 4 below:

Figure 4: Abradability and Frictional Work Variables

Some more advanced methods independently attempt to quantify tire wear by isolating all but a

few factors. Some of these tire wear formulas, which have received wide attention, include

Equation 7 below, which considers abrasion pattern, slippage, and temperature effects while

P a g e | 11

Equation 8 considers fatigue theory and the geometry of the contact surface (but does not include

temperature), and Equation 9 considers tire and road material properties:[8]

𝑅𝑊 = 𝜃 2 ∗ 𝑝 ∗ 𝑓 ∗ 𝑟0 (1 + 𝛼(𝑡𝑠 − 𝑡0 ) + 𝑐 ∗ 𝑑)

Eq. 7

𝑅𝑊 = 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡 ∗ (𝐸/𝜎0 )𝜇 𝛿−𝛽𝛿−1 (𝜃𝑎)2+𝛽𝛿 /(2 + 𝛽𝛿)

Eq. 8

𝑅𝑊 = 𝐾 ∗ (𝑃 ∗ 𝜃 2 + 𝑄 ∗ 𝜃 3.5 )

Eq. 9

Where RW is the rate of wear, θ is the slip angle, p is the resilience of the wheel, f is the wheel

stiffness, α is the temperature coefficient, ts is the tire surface temperature, t0 is the reference

temperature, c, d and K are constants, E is the modulus of elasticity, σ0 is the ordinary tensile

strength, μ is the coefficient of friction, δ is the fatigue exponent, β is the parameter specifying

track roughness, a is the length of contact area, and P and Q are material constants.

Presently, Hans Bastiaan Pacejka has published works that are now the standards in tire

dynamics.[9] Pacejka has developed a series of tire design models over the last two decades,

which have been dubbed the “magic formula” because there is no particular basis for the

structure of the equations chosen. However they appear to fit a wide variety of tire constructions

and operating conditions, are reasonably accurate, easy to program and solve quickly, which

makes the Pacejka tire models widely used in professional vehicle dynamics simulations and

racing car games.

Each tire is characterized by 10-20 coefficients, such as lateral and

longitudinal force and self-aligning torque, as a best fit between experimental data and the

model. These coefficients are then utilized to generate equations representing how much force is

generated for a given vertical load on the tire, camber angle and slip angle. The general form of

the magic formula is presented in Equation 10 below:

𝑅(𝑘) = 𝑑 ∗ sin{𝑐 ∗ arctan[𝑏(1 − 𝑒)𝑘 + 𝑒 ∗ arctan(𝑏𝑘)]}

Eq. 10

P a g e | 12

Where b, c, d and e represent fitting constants and R is a force or moment resulting from a slip

parameter, k. An example of a Pacejka’s magic formula tire model curve is presented in Figure

5 below:

Figure 5: Pacejka Magic Formula Tire Model Curve

CONCLUSION:

The tribological system of tire wear may be broken up into the subtopics of wear mechanisms

specific to the tire and the tire wear model. However, it appears that while wear mechanisms has

been well defined for tire wear in the discipline of tribology in relation to tire wear, tire wear

models have steadily evolved from more complex and accurate equations.

It is clear that

tribological system of tire wear is critical in the application and field of vehicle dynamics. To

further expand upon the material discussed within this report, one could further explore the

accuracy of the latest tire models (Pacejka) to estimate the tire-road friction during steady-state

longitudinal and corner maneuvers. While it appears that Pacejka tire models are widely used in

P a g e | 13

professional vehicle dynamics simulations and racing car games due to its ability to fit a wide

variety of tire constructions and operating conditions, are reasonably accurate, easy to program

and solve quickly, it does not

work for low speeds (from around pit-entry speed) once

implemented into computer code.[9] This is due to a velocity term in the denominator which

makes the Pacejka formula diverge, causing the force on the tire to go infinite. As one starts to

slow down the car in the simulation, a purely artificial increase in the grip forces results from

Pacejka’s formula divergence, the car becomes perversely and incorrectly harder to control.[10]

An alternative to Pacejka tire models at low speeds is to utilize the brush tire models, which may

be analytically derived.[11]

P a g e | 14

REFERENCES:

1) Automotive Tribology; A. Kapoor, S.C. Tung, S.E. Schwartz, M. Priest, R.S. DwyerJoice; 2001

2) The Tyre Pavement Interface, in STP 929, American Society for Testing and Materials,

IX-XV; M.G. Pottinger, T.J. Yager; 1986

3) Tire Tech: Tire Aging - Part #1; Tire Rack,

http://www.tirerack.com/tires/tiretech/techpage.jsp?techid=138; 2015

4) Wear; Wikipedia, http://en.wikipedia.org/wiki/Wear; 2015

5) Swedish Research on Tyre Consumption - Modelling Tyre Consumption; O. Nordstrom,

O. Andersson; 1996

6) Affinia Group - Be Aware of Tire Wear;

http://www.raybestoschassis.com/training/problem-solution/be-aware-of-tire-wear; 2012

7) Study on the Simulation of Radial Tire Wear Characteristics; Automotive Engineering

College – Tongji University - G. Tong, X. Jin; 2012

8) Tire Wear Model; Department of Mechanical Engineering - Carnegie-Mellon University,

E. Saibel and C. Tsai; 1969

9) Hans B. Pacejka: http://en.wikipedia.org/wiki/Hans_B._Pacejka; 2015

10) The Physics in Games - Real-Time Simulation Explained, channel9.msdn.com, Minutes

29:53-33:45; B. Beckman; 2007

11) European Control Conference - Brush Tire Model with increased Flexibility,

www.nt.ntnu.no/users/skoge/prost/proceedings/ecc03/pdfs/317.pdf; J. Svendenius, B.

Wittenmark; 2003