4A6(1) Disaster Case Study - Kemper Arena Roof Collapse - Group 4.docx

advertisement

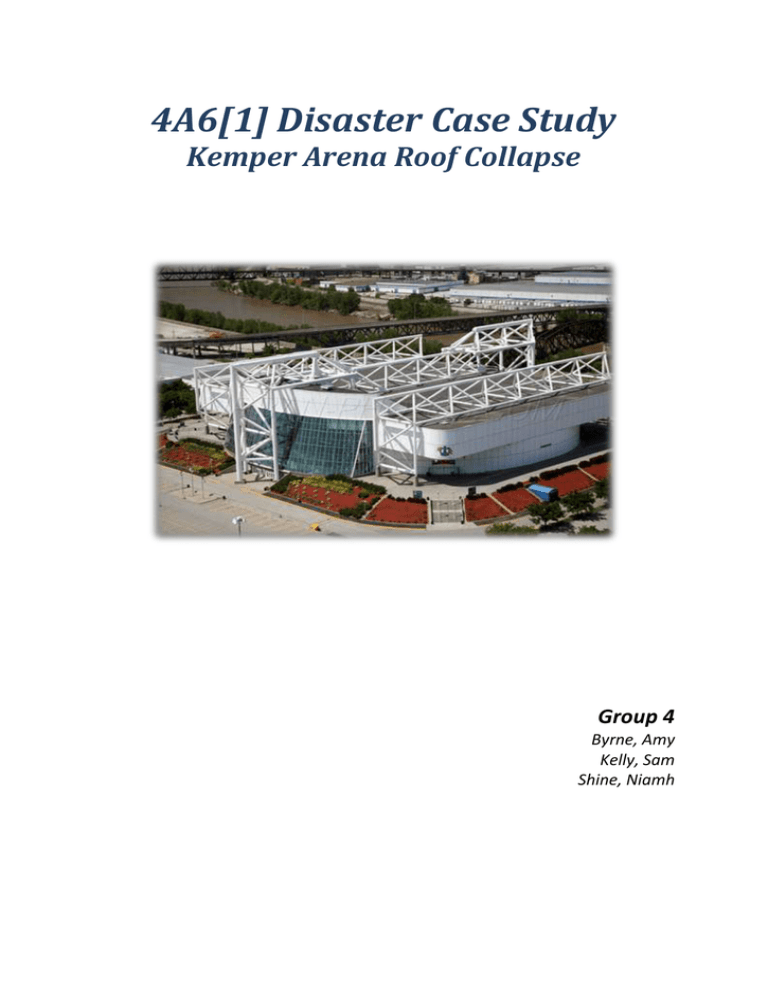

4A6[1] Disaster Case Study Kemper Arena Roof Collapse Group 4 Byrne, Amy Kelly, Sam Shine, Niamh Introduction The Kemper Arena was built in 1973 as the new home for the local Kansas City King basketball team with a capacity of 17,600 seats at a cost of $23.2million. The Kemper Arena was built on the site of the old Royals Horse and Cattle Fair and was named after R. Cosby Kemper, one of the city’s founding fathers. The arena was built primarily for the basketball team but was also used to host other sports and events such as rodeos, ice shows, football (association) games and large conventions, including the 1976 National Republican Convention. The design of the arena won an American Institute of Architects award in 1976. Design The arena was designed by Helmuth Jahn of C.F. Murphy and was located on an elevated, isolated site on the outskirts of the city. The design of the roof was such that it was suspended from above, as is illustrated in Figure 1. This was done so that the arena could Figure 2 feature uninterrupted sightlines. The roof measured 97x108m and was suspended on hangers from three large space frame cantilever trusses. Each truss was 16.5m wide and space 30m apart. The pipe sections making up these trusses were as large as 1.2m in diameter. The roof structure consisted of reinforced concrete supported on a light steel open web joists with steel angle chords. The weight of the roof itself was 1.3kN/m 2 and the additional load it was designed to carry was 1.25kN/m2 (rain, mechanical systems and other hanging loads). Each, of the 42, hangers was designed to carry 622kN in tension whilst supporting the roof. They had to resist the horizontal wind force which tended to move the roof horizontally like a gigantic inverted pendulum. Between the bottom of the hangers and the top chords of the steel trusses, the connection consisted of a steel base plate and a thin Figure 1 plate of plastic composite, Micarta, to ensure a good contact and to ensure the connection is not entirely rigid. The connection for the hangers used ASTM A490 high-strength bolts. Storms frequent the region and as part of an effort to reduce the storm water run-off into the city’s sewers, the roof was designed to hold water as a temporary reservoir. The roof had eight 120mm diameter drains and once the water depth exceeded 50mm, water could pour out over scuppers. The stiffness of a flat roof, such as the one used in the design of the Kemper Arena, is important in order to prevent ‘ponding’. ‘Ponding’ is the term given to a flat roof collecting rainwater and deflecting under the weight, which in turn holds progressively more water. Certain problems in the design arise immediately, before disaster struck. The bolts used in the hangers, ASTM A490, are not recommended for use with fatigue or variable loads as the design codes warn against this. This is something that may not have been taken account for in the design of the arena. This could have been possibly due to the factor of safety being adequately high under design loads. The frequency of storms and the location of the site would mean many varying loads would be acting on the structure over its lifetime. The number of drains on the roof, 13, was not enough as the local legal code required 8 times as many drains. The feature of having the roof as a temporary reservoir could only aggravate ‘ponding’ and be cause for largely variable loads depending on the amount of rainfall in a given storm. Disaster On June 14th, 1979 at approximately 6.45 p.m. the roof of the Kemper Arena collapsed. It was during a storm, which resulted in downpours of 108 mm/hr and winds of 112 km/hr. A single employee was the only person in the arena at the time of the collapse. He described the sound of the roof collapsing as explosive. A large 60x65m section of the roof suddenly collapsed onto the arena floor underneath. This in turn caused a massive air pressure surge which blew out some of the walls. The overall result was a stadium full of broken and twisted chunks of steel. Throughout the arenas 6 year lifespan it had experienced and withstood greater storms than the one that had caused the dramatic collapse. Kansas is situated in an area which is known to regularly encounter severe storms and rainfall. Therefore this particular storm should not have been a major concern. But due to several factors, including ‘ponding’, fatigue and lack of redundant members, the storm managed to cause the roof of the arena to fail. Investigation All parties involved appointed their own investigators in order to establish the cause as soon as possible to avoid lengthy and costly litigation. It became apparent early in the investigation that there was no single cause. James L. Stratta, a civil engineer and failure analyst appointed by the city authorities, believed that the A490 bolts, connecting the suspended roof and space frame, were to blame. “The bolts broke at the root of the thread. It appears to be a direct tension failure,” he observed. He added, “They may have failed because of something else”. However, bolts taken from the disaster site were sent for stress testing and met their design specifications, which applied to dead loading. Some experts believed that the cause of the roof collapse was due to ‘ponding’. The approx. 10,500m2 roof contained eight 120mm diameter drains, placed towards the centre because the roof’s inverted pitch, each of which could discharge water at a rate of 0.0015m3/s. Investigators found that the drains were not blocked, however, Kansas City code required one such drain for every 186m2 of roof, which meant that the arena should have had a minimum of 65 drains. Substantial ‘ponding’ had taken place and although it had not exceeded the design load-bearing capacity of the roof, it had in fact contributed to failure. Figure 3 The main issue with the design of the arena was its flexibility. It is well known that tornadoes are a common occurrence in Kansas so wind would have been a big factor in the design of the building. According to Roger McCarthy from Failure Analysis Associates (FaAA), “It was open, more airy, and much [lighter] – inevitably there was greater flexibility in this structure.” Because the roof was so flexible, the water which had accumulated was able to move around, this along with the high windspeeds meant that the roof was subjected to a cycle of increasing loads causing increased deflection and the roof became unstable. The A490 Figure 4 bolts, although passing design specification, are not designed for dynamic loading. The movement of the roof fatigued and loosen the bolts causing them to fail. Stratta reported “They [the bolts] apparently failed at between one-fourth and one-fifth of what they should have been able to carry”. The University of Missouri tested the bolts and concluded that the bolts would loosen if subjected to a torque of between 540kNm and 1020kNm. The bolts should have been designed to withstand 3,800kNm of torque. Lack of redundancy was another major factor that led to its collapse. After one hanger failed due to bolt fatigue, the remaining hangers could not withstand the additional loading. Conclusions The cause of the collapse of the Kemper Arena roof contributed to the expansion of the knowledge base of the international Engineering community. The collapse highlighted the importance of paying attention to stiffness as well as strength of a structure. Analysis of fatigue, stiffness and strength is required for good design. Roger McCarthy of the FaAA sums up the main lesson to be learnt from this disaster: “Sometimes we get too close to the margin between strength and load and we forget that there are really two things you have to worry about in a structure. One is strength and the other is the stiffness. Sometimes the stiffness will govern the design. Even though you don’t need the extra material for strength you may need the extra material for rigidity. The key lessons learnt were evident when the arena roof was rebuilt. The steel bolts and plates were replaced by much more ductile single steel part for each hanger. The roof was raised and fourteen drains were added. An electronic monitoring device was installed to give advanced warnings of any motion problems in the roof. References Why Buildings Fall Down: How Structures Fail - Matthys Levy and Mario Salvadori - W.W. Norton, 2002. Collapse : Why Buildings Fall Down - Philip Wearne - Channel 4 Books, 1999. Beyond Failure: Forensic Case Studies for Civil Engineers - Norbert J. Delatte Jr. Ph.D., P.E. ASCE Press.