Final Design Proposal - 3/11/04

Superconducting

Solenoid Punch

Team Supercool

Andy Lin

Chris Kinney

Naomi Kohen

David Schoen

Superconducting Actuator

Zero resistance at low T

Electrical actuator:

Electrical E Mechanical E

American Superconductor

Goal: HTS solenoid punch

Why superconducting?

Low resistance Higher efficiency

Higher current density Larger field

Fewer turns Simple design and manufacturing

Superconductor Physics

Impenetrable by external magnetic fields (up to a point)

Type I & II Superconductors

Cooper Pairs

BSSCO 2223: Our Tape

Provided by American

Superconductor

4 mm (w) x 0.21mm (t)

Critical Current rating 85

– 108 A

Critical Temp (T c

) 110K

Currently 2 pieces; 4 and

50 m long

BSSCO 2223: I

C vs. H

The Punch

Use solenoid for magnetic field

An iron core accelerates in the field

A strong field will produce a significant force.

Coil Dimensions

Inner Coil between 50 mm and 100 mm in diameter

Coil height approximately 75mm

Between 320 and 160 turns with 50 meters of wire

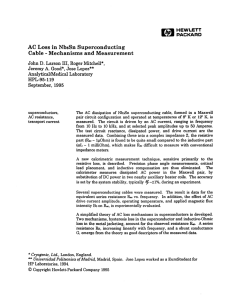

Critical Current Setup

Critical Current

Measurements

Voltage vs. Current

10

1

0.1

0.01

0 50 100

Current (A)

150

Trial 1, 77K, 2/28/04

Trial 2, 77K, 2/28/04

Trial 3, 77K, 3/2/04

Coil Radius Setup

0.1

0.01

0.001

0

1

Coil Radius Measurements

Voltage vs. Current

50

Current (A)

100 150

Trial 1

Trial 2

The Apparatus

The Apparatus

Materials Choice

PVC

Inexpensive

Machinable

Diamagnetic

Al

Inexpensive

Easily Machinable

Paramagnetic

Durable

400

300

200

100

Estimates

0.1

0.2

Displacement (m)

0.3

0.4

Estimates

120

100

80

60

40

20

0.1

0.2

Displacement (m)

0.3

0.4

Comparisons

Future Considerations

Running colder than 77K

Making a taller or shorter coil

Punch striking surface

Punch shape

Retraction Mechanism

Pulse (with capacitor)?

Tests

Obtain comparable copper solenoid

Magnetic field

Force

Energy density per mass

Schedule

Questions?

Calculating Force

For Loop

B

NIr

2

2 ( r

2 x

2

)

3

2

Force: dF

A

M

B

dx

Magnetization of Iron: 334225 A/m