PI Responsibilities

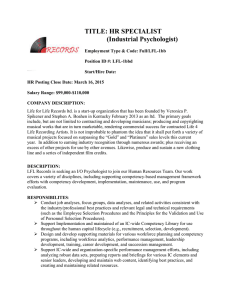

advertisement

Leading Health and Safety at Work Health and Safety Management Responsibilities of Principal Investigators and Managers Why Health and Safety Is Important • Reputation – University of Nottingham aims for excellence in teaching and research – Quality in teaching and research is achieved through quality in all aspects of operations. – Bad publicity from unsafe, unhealthy or environmentally damaging events undermines this. • Moral imperative – To provide a safe and healthy working environment – Clear conscience Why Health and Safety Is Important • Legal requirements – Law specifies standards – Penalties if not followed • Financial Reasons – Staff absences – Lost output/data – Damaged equipment – Compensation pay-outs and insurance premiums – Uninsured costs >>> Insured costs Legal Environment • Statutory Law • Health and Safety at Work etc Act 1974 • Duties towards employees, students and visitors – Ensure, so far as is reasonably practicable, health, safety and welfare at work • Management of Health and Safety at Work Regulations 1999 – Duties on manager to ensure the above – Risk assessment!!! • Corporate Manslaughter and Corporate Homicide Act 2007 – Death resulting from systemic failures to manage health and safety – Implies senior management failures in risk management – See Podcast for further information Penalties • Prosecution – fines and imprisonment. • Prohibition Notice – stop work now • Improvement notices – put certain measure in place within a specified time • Corporate Manslaughter Penalties – Unlimited fine – Publicity order Civil Liability • Common Law Duty of Care owed to employees, students & visitors. • Failure can result in personal injury claims for negligence. Organisation – lines of responsibility Safety Committee Council Registrar Head of School/Service n University Safety Officer Managers/PIs/ Snr Academics School/Section Safety Officers Lab safety Monitors Individuals Responsibility Advice Information Safety Responsibilities • • • • • Risk assessment Training Competency Supervision Monitoring • Detailed information can be found in the University’s Safety Management Standard: ‘Effective Safety Management’: http://nottingham.ac.uk/safety/safetymanagement/esm/effective-safety.aspx Risk Assessment • • • • • For all hazardous activities/procedures New procedures New & existing equipment Written SOPs [standard operating procedures] Signed off by PI/Snr academic/manager Risk Assessment continued • Procedural – – – – – Substances [ e.g.chemicals, biological material] Equipment Manual handling Cylinders Cryogenics • DSE • Lone working Training & Competence • • • • Identify training needs – initial & ongoing Ensure training delivered by competent person Assess competency Record training and attainment of competency (specific record form, PSRF or e lab book) Training Delivery • • • • University & External courses Local induction Job/task specific training (techniques & equipment) Refresher training – When procedure/equipment changes – High risk operations – Infrequent operations – Following accident/incident – Where competency is in question Competency Assessment • Assess practical skills & knowledge • Assessment by competent person • Methods of assessment • Written test [ e.g. induction questionnaire • Verbal discussion/questioning • Observation [ for practical tasks] • Self assessment [ where appropriate] • Continual assessment – ensure standards maintained Supervision Levels of supervision are determined by: • the severity of the hazard and • the complexity of the control measures required to reduce risk • the competence of the person Source HSE – HSG 65 Monitoring • Active monitoring – – – – Local housekeeping checks – recorded. Regular meetings [ present findings of above] Regular entry into the lab by PI – to check School safety inspections & audits • Accident/incident/near misses – Reported – Investigated Remember • You can delegate safety management duties • You cannot delegate legal responsibility • You remain accountable in law for the safety of students/staff that you manage/supervise