PCCI Investigation Using Variable Intake Valve Closing in a Heavy Duty Diesel Engine

advertisement

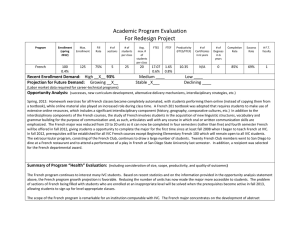

PCCI Investigation Using Variable Intake Valve Closing in a Heavy Duty Diesel Engine Ryan Nevin, Professor Rolf Reitz and Manuel Gonzalez Funding Sponsors: Caterpillar and US Department Of Energy Solenoid Driven IVA System 0.20 6 0.158mm 0.4 0.35 80 0.3 60 0.25 40 0.2 0.15 20 0.1 0 0.05 -20 0 0 5 10 15 20 IVC143 P IVC143 HR Value 1737 3.50 (30% Load) 55 143, 115, 100, 85 25 0.2 to 0.3 ULS 2007 Diesel 25 IVC85 P IVC85 HR -150 -120 -90 Intake Pressures (kPa) Tested 4mm Lift 1.5mm Lift NAHRR 100°BTDC 3.00 70°BTDC 85°BTDC 2.50 IVC143 IVC115 IVC100 IVC85 IVC85-CAM 193 207 207 236 207 207 221 221 248 221 221 235 234 262 241 --248 ----259 0.2 0.15 85 Later IVC 70 0.1 0.05 85 115 143 130 115 0 0 0.5 1 1.5 2 2.5 3 3.5 NOx (g/kW-hr) 2007 ULS Fuel Pre-2007 Fuel IVC85 CAM 10 20 30 40 IVC130 IVC70 IVC115 IVC100 IVC85 IVC60 0.15 0 1.00 -30 0.50 -25 -20 -15 0.00 -10 -5 0 5 10 CA-ATDC -0.50 -190 -175 -160 -145 -130 -115 -100 -85 4mm Lift -70 1.5mm Lift Boost Increase 0.02 0.015 0.01 0.005 0 0.5 1 1.5 2 2.5 IVC143 IVC85 2010-NTE IVC115 IVC85-CAM IVC100 2007 • NOx decreases with IVC as well as intake pressure increase since intake air acts as a diluent • PM decreases with IVC by equivalence ratio increasing, and the necessary temperatures for oxidation are met IVC143 IVC130 IVC70 IVC60 IVC115 3 0.1 0.05 0 -145 -130 -115 -100 -85 -70 -55 IVC100 IVC85 PM • NOx decreases with lower in-cylinder temperatures, while PM increases due to less available oxygen to oxidize soot • Late IVC (i.e. 60°BTDC) is capable of suppressing combustion 2010 Emissions Search Factor Speed (rev/min) Fuel Flow (kg/hr) EGR % SOI (CA-BTDC) IVC Timings (CABTDC)Temperature (K) Intake 0.025 0.15 1 0.8 0.6 0.4 0.2 0 -160 NOx 130°BTDC 1.50 0.2 0.1 0.05 2.00 0.25 IVC (CA-ATDC) 115°BTDC 0.25 70 0 -60 0.25 IVC143 NOx (g/kW-hr) IVC70 P IVC70 HR -10 2 1.8 1.6 1.4 1.2 PM (g/kW-hr) -180 0.2 0 IVC115 P IVC115 HR 100 *** Pressure and NAHRR curves shown are of 2007 ULS Diesel fuel; combustion of fuels were similar Factor Speed (rev/min) Fuel Flow (kg/hr) SOI (CA-BTDC) IVC Timings (CA-BTDC) EGR Rate % Equivalence Ratio Fuel Type CA-ATDC PM (g/kW-hr) • Average decrease of 50% in PM emissions by using 2007 ULSD over pre-2007 #2 diesel fuel • Although enough oxygen is being entrained into the cylinder, the soot increases after a certain IVC timing since the combustion temperatures drop below necessary oxidizing temperatures -5 -210 IVC Timing and Intake Pressure Sweeps 0.45 -10 -240 IVC143 120 -15 -270 128° 0.5 -20 -300 CA ATDC 140 -25 -330 3.50 Preliminary testing found increased valve lift provided better combustion phasing -20 CA-ATDC 4.00 NAHRR Equivalence Ratio -30 143°BTDC 4.50 100 Pressure (bar) Value 1737 3.55 (30% Load) 4.47 0 55 0 IVC143 Constant A/F Ratio IVC Sweep with Different Diesel Fuels Factor Speed (rev/min) Fuel Flow (kg/hr) Air Flow (kg/min) EGR Rate % SOI (CA-BTDC) 5.50 CA ATDC EVC = -355 deg ATDC IVC = -143 deg ATDC EVO = 130 deg ATDC IVO = 335 deg ATDC Hydraulically Driven Electronically Controlled Unit Injector (HEUI 300B) Up to 150MPa 40 20 1.00 0 -0.50 -360 Quiescent 60 Value 1737 3.25 (25% Load) 184 55 0 Value 1737 3.0 (25% Load) 40 55 143, 85 (Solenoid) 305 • NOx decreased by factor of 2.5 solely through late IVC • 2010 NTE NOx and PM levels met through lowering temperature and increasing equivalence ratio through use of late IVC timing Run Intake Pressure (kPa) Intake Flowrate (kg/min) IVC (CA-ATDC) NOx (g/kW-hr) HC (g/kW-hr) PM (g/kW-hr) Equivalence Ratio Φ 3 6 9 184 184 172 2.52 2.03 1.86 -143 -85 -85 0.832 0.339 0.239 0.932 1.4232 1.6085 0.0103 0.0206 0.018 0.265 0.2886 0.3391 University of Wisconsin Engine Research Center 0.025 6 8 0.02 9 0.015 0.01 3 0.005 0 0 0.2 0.4 0.6 0.8 1 NOx (g/kW-hr) Case 3 (IVC143) Case 6 (IVC85) Case 9 (IVC85) 2010-NTE Case 8 (IVC85) 140 0.4 120 0.35 0.3 100 0.25 80 0.2 60 0.15 40 0.1 20 0.05 0 0 -30 -20 -10 0 10 20 30 CA ATDC IVC143 (Case 3) P IVC85 (Case 6) P IVC85 (Case 9) P IVC143 (Case 3) HR IVC85 (Case 6) HR IVC85 (Case 9) HR 40 NAHRR Injection Pressure Nozzle Holes Nozzle Hole Diameter Spray Angle 7.00 2.50 2.44 liters Valve Lift (mm) Injector Type 8.50 4.00 PM (g/kW-hr) Valve Train (4 valve) 70°BTDC 10.00 80 NOx (g/kW-hr) 16.1 : 1 85°BTDC 130°BTDC 100 PM (g/kW-hr) 137.2 mm x 165.1 mm 100°BTDC 115°BTDC 11.50 Mexican Hat with Sharp Edge Crater Piston Pressure (bar) 14.50 13.00 Factor Speed (rev/min) Fuel Flow (kg/hr) Intake Pressure (kPa) SOI (CA-BTDC) EGR Rate % 120 16.00 Valve Lift (mm) Bore x Stroke Compression Ratio Displacement Combustion Chamber 140 Valve Lift Curves Caterpillar 3401 SCOTE (Single Cylinder Oil Test Engine) - single cylinder - direct injection - 4 valve Engine Baseline IVC Sweep Pressure (Bar) Experimental Setup