Postprint_FST_2014_V59_P376.doc

advertisement

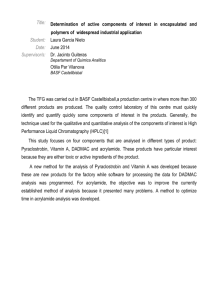

1 Contribution of peptides and polyphenols from olive water to acrylamide formation in 2 sterilized table olives 3 4 Francisco Javier Casado*,a,b, Alfredo Montañob and Reinhold Carlea 5 6 7 a 8 University, Garbenstrasse 25, D-70593 Stuttgart, Germany 9 b 10 Institute of Food Science and Biotechnology, Chair Plant Foodstuff Technology, Hohenheim Instituto de la Grasa (C.S.I.C.), Apartado 1078, 41012 Seville, Spain *Tel.: +49(0)711-45923125, fax: +49(0)711-45924110, e-mail: javierhebrard@ig.csic.es 11 12 Running title: Peptides and polyphenols from olive water are acrylamide precursors 13 14 15 16 17 18 19 20 21 22 23 24 25 26 1 27 Abstract 28 29 To confirm the role of peptides as principal precursors of acrylamide formation in sterilized 30 table olives, peptides from olive water were fractionated. After their partial fractionation by 31 solid phase extraction (SPE) and ultrafiltration (< 10,000 Da), respectively, small peptides 32 from olive water were isolated by size-exclusion chromatography (SEC). In the fractions 33 collected, peptides and polyphenolic compounds were determined colorimetrically, and 34 acrylamide was quantitated by LC-MS/MS after heating of the samples. Subsequently, 35 peptides 36 time of flight mass spectrometry (MALDI-TOF/TOF-MS), and polyphenols were analyzed by 37 LC-MS in the respective fractions. Finally, peptides containing fractions were purified on a 38 polymeric resin (Amberlite XAD 16HP) to remove unbound phenolic compounds by 39 adsorption. The results of the different experiments performed in complete absence of free 40 asparagine and reducing sugars strongly support small peptides bound to polyphenols to be 41 the principal precursors of acrylamide in sterilized table olives. were characterized by matrix-assisted laser desorption/ionization-tandem 42 43 44 45 Keywords: Acrylamide · olives · peptides · fractionation · size-exclusion chromatography · 46 peptide-polyphenol complexes 47 48 49 50 51 52 2 53 1. Introduction 54 55 Acrylamide, a chemical compound classified as “probably carcinogenic to humans” by 56 the International Agency for Research on Cancer (IARC, 1994), was first detected in heated 57 carbohydrates-rich foods in 2002 (Tareke, Rydberg, Karlsson, Eriksson & Tornqvist, 2002). 58 The Maillard reaction between free asparagine (Asn) and reducing sugars and further 59 carbonyl sources, respectively, has been confirmed as the major pathway of acrylamide 60 formation in foodstuffs (Mottram, Wedzicha & Dodson, 2002; Stadler et al., 2002; Gökmen 61 & Palakzaglu, 2008). In general, the highest levels of acrylamide have been found in 62 carbohydrate-rich foods from potato, wheat and other cereals, and coffee (Friedman, 2003). 63 High acrylamide levels (from 200 to 2000 μg/kg) have been detected in black ripe 64 olives, one of the main types of table olive commercialized worldwide in which sterilization 65 treatment is compulsory (FDA, 2006; Casado & Montaño, 2008). Nevertheless, it has been 66 demonstrated that acrylamide formation in sterilized olives follows a different pathway, since 67 acrylamide levels of olives did not correlate with the contents of free Asn and any of the 68 reducing sugars determined prior to sterilization (Amrein, Andres, Escher & Amadò, 2007; 69 Casado & Montaño, 2008). Compared with potato and cereal products, little information is 70 available on acrylamide in sterilized black ripe and green ripe olives. Up to now, the 71 mechanism of acrylamide formation in olives is still unknown. 72 A detailed study dealing with heated model peptides and olive water fractions has 73 been reported previously (Casado, Montaño, Spitzner & Carle, 2013). According to our 74 findings, the role of free Asn and glucose, being the main reducing sugar in olives, as 75 acrylamide precursors in these fruits has been ruled out, suggesting peptides smaller than 76 10,000 Da to be the principal precursors of acrylamide formation in heated table olives. In the 77 absence of free Asn, only fractions containing peptides/proteins obtained by partial 78 fractionation of olive water by solid phase extraction (SPE) and precipitation with cold 3 79 acetone, respectively, generated significant amounts of acrylamide upon heating at usual 80 sterilization conditions (121 ºC for 30 min). 81 The aim of the present work was to fractionate and isolate peptides from olive water to 82 confirm their putative role as precursors of acrylamide in sterilized olives. Due to the complex 83 fruit matrix, isolation of peptides was to be expected very challenging, considering the 84 multiple interactions of peptides or proteins with phenolic compounds. Consequently, olive 85 water from untreated green olives was subjected to size-exclusion chromatography (SEC) 86 after partial fractionation by SPE and ultrafiltration. Peptides and polyphenolic compounds of 87 the fractions collected were measured colorimetrically. For the quantitation of acrylamide in 88 the heated samples, liquid chromatography-tandem mass spectrometry (LC-MS/MS) was 89 applied. Subsequently, peptides were further characterized by matrix-assisted laser 90 desorption/ionization-tandem time of flight mass spectrometry (MALDI-TOF/TOF-MS), and 91 polyphenols were determined by liquid chromatography-mass spectrometry (LC-MS) in the 92 respective fractions. Finally, phenolic compounds were removed from the peptides containing 93 fractions using a polymeric resin to elucidate the mechanism of acrylamide formation in table 94 olives. 95 96 2. Materials and methods 97 98 2.1. Chemical and Materials 99 100 Acrylamide (99%) was purchased from ICN Biomedicals (Eschwege, Germany), 101 2,3,3-D3-labeled acrylamide (98%) was from Cambridge Isotope Laboratories (Andover, MA, 102 USA). Formic acid and acetonitrile (ACN), both gradient grade, ammonium acetate (99%), 103 ethanol 104 hexacyanoferrate (Carrez I) and zinc acetate (Carrez II) were provided by VWR (Darmstadt, (98%), acetone, ethyl acetate, methanol, 4 hydrochloric acid, potassium 105 Germany). Glacial acetic acid and trifluoroacetic acid (TFA) were from Merck (Darmstadt, 106 Germany). 2,5-dihydroxybenzoic acid (DHB) and α-Cyano-4-hydroxycinnamic acid (HCCA), 107 were obtained from Bruker Daltonics (Bremen, Germany). Deionized water (Sartorius Arium 108 611 Ultrapure water system) was used throughout. Solid phase extraction cartridges (Isolute 109 Multimode, 1000 mg) were obtained from IST (Hengoed, Mid Glamorgan, UK). Silica-based 110 bonded-phase cartridges (Sep Pak Vac 20 cc/5g C18) were purchased from Waters (Milford, 111 MA, USA). Chem Elut cartridges for solid phase supported liquid-liquid extraction and 112 Hydromatrix diatomaceous earth were from Varian (Darmstadt, Germany). 113 114 2.2. Olive water extraction 115 116 Green olives (5 kg) of cv. ‘Hojiblanca’ (Seville, Spain) from a local processor were 117 used. Olives were pitted and homogenized using a mixer. The olive water was obtained by 118 pressing the mash using an hydraulic laboratory press (Hafico, HP-2, Düsseldorf, Germany) 119 and twofold centrifugation at 20,000g for 20 min at 20 ºC to remove the olive oil. The olive 120 water was stored at - 20 ºC until the different experiments were performed. After extraction, 121 the pH of the olive water was 4.4. 122 123 2.3. Partial fractionation of olive water 124 125 Peptides from olive water were fractionated according to the scheme showed in Fig 1. 126 To the partial fractionation of olive water by SPE, Sep Pak Vac C18 cartridges were 127 conditioned with methanol and water. After pH adjustment to 3.0 using HCl, aliquots (10 mL) 128 of olive water were filtered through a 0.45 µm syringe filter, loaded, and slowly (1 mL/min) 129 passed through the cartridges. Two different fractions were recovered: (1) fraction A, an 130 aqueous fraction consisting of the eluate, and the retentate obtained after elution from the 5 131 sorbent with 15 mL of water; and (2) fraction B, comprising the less polar fraction eluted 132 from the sorbent with 15 mL of methanol. Whereas fraction A was discarded, fraction B was 133 evaporated to dryness in a rotary evaporator, resuspended in 10 mL of water, and the pH was 134 adjusted to the initial value (≈ 4.4). Fraction B was used for the fractionation of peptides by 135 SEC after ultrafiltration. 136 137 2.4. Ultrafiltration 138 139 Fraction B (see section 2.3.) was re-circulated through a stirred ultrafiltration cell 140 model 8003 containing a cellulose membrane with a molecular weight cut-off of Mr 10,000 141 (Millipore, Beverly, MA, USA). Aliquots of the retentate (fraction C) and permeate (fraction 142 D), resuspended with water, were adjusted to pH 4.4. Fraction D was used for the 143 fractionation of peptides by SEC. 144 145 2.5. Fractionation of peptides by size-exclusion chromatography 146 147 A 5 mL of fraction D (permeate) was concentrated to 1 mL under reduced pressure. 148 The concentrate was applied to a glass column (Superformance, 600 x 26 mm, Merck, 149 Darmstadt, Germany) filled with Toyopearl HW-55F (Tosoh, Stuttgart, Germany). Elution 150 was performed at room temperature using 0.3 mol/L ammonium acetate buffer, pH 4.0. The 151 flow-rate of 2 mL/min was produced using a HPLC compact pump (Bischoff, Leonberg, 152 Germany). The absorbance at 280 nm was measured with a SPD-10AV UV/Vis detector 153 (Shimadzu, Duisburg, Germany). The eluate was collected in 40 mL fractions. The 154 fractionation was performed in sextuplicate. Appropriate fractions collected after six runs 155 were pooled, freeze-dried, and resuspended in water. The pH of the fractions ranged from 5.7 156 to 6.0. 6 157 2.6. Adsorptive removal of phenolic compounds from olive water fractions using polymeric 158 resin 159 160 Phenolic compounds from appropriate olive water fractions were removed by 161 adsorption with a polymeric resin, Amberlite XAD 16 HP (Rohm and Haas, Philadelphia, PA, 162 USA), following a method developed by Weisz, Schneider, Schweiggert, Kammerer and 163 Carle (2010) with several modifications. 164 The resin (15 g) was activated overnight by soaking in 96% EtOH (5 mL/g). The same 165 volume of deionized water at 50 ºC was used to remove the alcohol from the resin beads prior 166 to the experiments. Subsequently, the adsorbent material was conditioned by purging with 3 167 mL/g of NaCl solution (1.3 mol/L, pH 6.0). 168 For each experiment, 15 mL olive water fraction adjusted to pH 6.0 was combined 169 with 1 g of pre-treated resin in a 50 mL screw cap flasks. To prevent polyphenol oxidation, 170 the flask was flushed with nitrogen. The suspension was stirred using a magnetic stirrer at 150 171 rpm in a thermostatted water bath at 20 ºC during 120 min. After separation of the solution 172 (fraction E), MeOH (20 mL) was added to the colored resin and the suspension was stirred at 173 room temperature for 30 min to elute the retained compounds. Subsequently, the colored 174 solution was evaporated to dryness in a rotary evaporator (30 ºC, 40 mbar), and resuspended 175 in 15 mL of water (fraction F). The pH of fraction F was adjusted to 6.0. 176 177 2.7. Heat treatment of model systems 178 179 Heat treatments were performed using 5 mL of the corresponding sample (aliquots of 180 fraction B after ultrafiltration, SEC or adsorption treatment with resin) filled in a stainless 181 tubular steel reactor (internal diameter 1 cm, length 8.5 cm). The reactor was sealed, and then 182 heated in a thermostatted oil bath at 121 ºC (±1 ºC) for 30 min in all experiments to mimic 7 183 sterilization conditions. After heating, the sample was immediately cooled in ice water for 3 184 min to stop the reaction. All heating experiments were performed in triplicate. 185 186 2.8. Sample preparation for acrylamide determination 187 188 For acrylamide determination, samples were prepared according to a method recently 189 published by Casado, Montaño, Spitzner and Carle (2013) using D3-acrylamide as internal 190 standard, and analysed by LC-MS/MS analysis. 191 192 2.9. Determination of acrylamide by LC-MS/MS 193 194 Acrylamide was determined by liquid chromatography-tandem mass spectrometry 195 (LC-MS/MS) according to the method developed by Claus, Weisz, Kammerer, Carle and 196 Schieber (2005). Analyses were carried out on an Agilent 1100 series HPLC system (Agilent, 197 Waldbronn, Germany). A Bruker Esquire 3000+ ion trap mass spectrometer (Bremen, 198 Germany) fitted with an electrospray ionisation (ESI) source was coupled on-line to the LC 199 system. Esquire Control software was used for data acquisition and processing. 200 Chromatographic separation of acrylamide was carried out on a Hypercarb column (100 x 2.1 201 mm; 5 µm) (Thermo Hypersil, Dreieich, Germany), equipped with a C18 guard column (4.0 x 202 3.0 mm) (Phenomenex, Torrance, CA, USA) at 30 ºC. The sample (20 µL) was separated 203 isocratically using a mobile phase composed of water/ACN/formic acid (99 mL/1 mL/0.05 204 mL) in water at a flow rate of 0.2 mL/min, within a total run time of 10 min. The mass 205 spectrometer was operated in the positive electrospray ionization mode (ESI+). Characteristic 206 fragmentation transitions m/z 72.3 > m/z 55.5 for acrylamide and m/z 75.3 > m/z 58.5 for D3- 207 acrylamide were recorded using multiple reaction monitoring (MRM). The signals at m/z 55.5 8 208 and m/z 58.5 were used for the quantitation of acrylamide and D3-acrylamide, respectively, 209 while the signals at m/z 44.5 and m/z 45.5 were used for qualification. 210 211 2.10. Colorimetric determination of peptides and polyphenols 212 213 Peptide contents of the fractions obtained by SEC were measured according to 214 Bradford (1976). Bovine serum albumin from Merck (Darmstadt, Germany) was used as a 215 standard. The absorbance at 595 nm was recorded against the reagent blank using a Cary 100 216 Cone spectrophotometer (Varian, Palo Alto, CA, USA). All determinations were performed in 217 triplicate. 218 The quantification of phenolic compounds was based on the method of Singleton and 219 Rossi (1965). Folin-Ciocalteu reagent was provided by Merck (Darmstadt, Germany). Caffeic 220 acid (≥ 95%, Roth, Karlsruhe, Germany) was used as a reference. The absorbance was read at 221 760 nm. All determinations were performed in triplicate. 222 223 2.11. Characterization of olive water peptides by MALDI-TOF/TOF-MS 224 225 Protein spectra, peptide mass fingerprints and MS/MS spectra of appropriate olive 226 water fractions were acquired on an Autoflex III MALDI-TOF/TOF mass spectrometer 227 (Bruker Daltonics, Bremen, Germany). The instrument was operated in the positive ion mode, 228 and externally calibrated using protein mass or peptide calibration standards (Bruker 229 Daltonics, Bremen, Germany), respectively. Samples were desalted using either C 4- or C18- 230 ZipTips (Millipore, Schwalbach, Germany) following the manufacturer’s protocols. Peptides 231 and proteins were eluted directly onto a stainless steel target using HCCA (5 mg/mL in 50% 232 ACN/ 50% 0.1% TFA) or DHB (20 mg/mL in 50% ACN/ 50% 0.1% TFA) matrix solutions, 233 respectively. Protein molecular weights in the range of 5-50 kDa were obtained in the linear 9 234 mode using an accelerating voltage of 20 kV. Peptide mass fingerprint data and MS/MS 235 spectra of olive water fractions were recorded in the reflector mode using an accelerating 236 voltage of 21 kV. Peptide mass fingerprint spectra were acquired in the m/z range between 237 700 and 5,000 Da. 2,000 laser shots per sample were acquired to ensure good signal/noise 238 quality for precursor ion selection. MS/MS analysis was done with a varying number of laser 239 shots. Flex Analysis 3.0 and Bio-Tools 3.0 software (Bruker Daltonics, Bremen, Germany) 240 were used for data processing. 241 242 2.12. Determination of polyphenols by LC-MS 243 244 LC-MS analyses were carried out using an Agilent HPLC series 1100 (Agilent, 245 Waldbronn, Germany). Polyphenols from appropriate olive water fractions were separated by 246 HPLC according to the method described by Desportes, Charpentier, Duteurtre, Maujean and 247 Duchiron (2000) with slight modifications. The separation was performed using a porous 248 graphitic carbon (PGC) Hypercarb column (100 x 2.1 mm; 5 µm) (Thermo Hypersil, 249 Dreieich, Germany), equipped with a C18 guard column (4.0 x 3.0 mm) (Phenomenex, 250 Torrance, CA, USA). The column was kept at 30 ºC. The volume injection was 50 µL. Eluent 251 A was 0.1 mL TFA/100 mL in deionized water, and eluent B was 0.1 mL TFA/100 mL in 252 ACN. The following gradient was used: 0-5 min, 0% B; 5-20 min, 0-10% B; 20-25 min, 253 10%B; 25-40 min, 10-30% B; 40-45 min, 30-50% B; 45-55 min, 50-100% B; 55-60 min, 100- 254 0% B, 60-70 min, 0% B. The flow rate was 0.8 mL/min. MS conditions were adopted from 255 Kaiser, Carle and Kammerer (2013). A Bruker Esquire 3000+ ion trap mass spectrometer 256 (Bremen, Germany) fitted with an ESI source was coupled on-line to the HPLC system Data 257 acquisition and processing were performed using Esquire Control software. Mass 258 spectrometer was operated in the negative ion mode. Mass spectra of the column eluate were 259 recorded in the range of m/z 50-1500 at a scan speed of 13,000 Th/s. 10 260 261 3. Results and Discussion 262 263 3.1. Partial fractionation by SPE and ultrafiltration of olive water 264 265 Olive water from untreated green olives (for olive water extraction see section 2.2.) 266 was partially fractionated by SPE. Two different fractions were recovered: fraction A, 267 comprising the permeate and the compounds eluted from the sorbent with water, and fraction 268 B, containing the retained compounds. Previous experiments carried out with the same olive 269 water in similar conditions demonstrated that: (1) after heat treatment (121ºC for 30 min) of 270 both fractions, significant amounts of acrylamide was formed in fraction B, while only traces 271 were found in fraction A, (2) peptides and/or proteins were presented in fraction B, and (3) 272 free Asn was in complete absence in fraction B (Casado, Montaño, Spitzner & Carle, 2012). 273 After discarding fraction A, fraction B was ultrafiltered to remove compounds having Mr 274 >10,000. The resulting fraction C and fraction D, resuspending with water, both with pH 275 adjusted to 4.4, were heated (121 ºC, 30 min) in the tubular reactor. Acrylamide was detected 276 in both, heated fraction D (1,217 ± 145 µg/L) and heated fraction C (147 ± 15 µg/L). 277 Acrylamide content in heated ultrafiltrate represented 89% of total. Although larger peptides 278 and/or proteins also contribute in minor way, these results suggested that the main acrylamide 279 precursors in sterilized fresh olive are peptides displaying Mr < 10,000. 280 281 3.2. Fractionation of peptides by SEC 282 283 A Toyopearl HW-55F column was used to fractionate peptides from fraction B. This 284 resin is a hydroxylated methacrylic polymer for SEC of proteins and peptides, having Mr > 11 285 1,000. Figure 2 shows a typical elution profile of the fraction obtained after partial 286 fractionation by SPE, and ultrafiltration of olive water on Toyopearl HW-55F. 287 288 Eleven different fractions were collected. Subsequently, all 11 fractions were subjected to polyphenols and peptides determination. 289 Results of polyphenols and peptides determination are displayed in Figure 3. As can 290 be seen, phenolic compounds were detected in all fractions with a maximum (0.075 g caffeic 291 acid/100 mL) in fraction 5, corresponding to the second highest peak of the elution profile. 292 Concerning peptides, fractions 2 to 4 exhibited the greatest concentrations (38, 36 and 38 mg 293 peptides/L, respectively). In general, a decreasing trend was observed from fraction 4 to 11. 294 Since the highest peptide concentrations were detected at the beginning of the elution profile, 295 most of the peptides contained in the ultrafiltrate were supposed to exhibit a Mr close to the 296 cut off of the ultrafiltration membrane (10,000 Da). 297 Figure 3 also displays the acrylamide contents of each fraction after heating of the 298 samples (121 ºC for 30 min). Different amounts of acrylamide were found in fractions 1 to 5, 299 whereas the compound was not detected in fractions 6 to 11. These results demonstrated that 300 fractions 2 and 3 generated the largest amounts of acrylamide (528 ± 31, and 416 ± 13 µg/L, 301 respectively). Taking into account all these findings, acrylamide precursors were mainly 302 accumulated in fraction 2 and 3. Therefore, both fractions were exclusively used for the 303 following experiments. 304 305 3.3. Characterization of olive water peptides by MALDI-TOF/TOF-MS 306 307 In the past decade, MALDI-TOF MS has become one of the most powerful tools for 308 the analysis of biomolecules including proteins and peptides. This analytical technique has 309 demonstrated increasing utility in the molecular weight determination and identification of 310 peptides. In an attempt to characterize the peptides present in fractions 2 and 3, both fractions 12 311 were subjected to MALDI-TOF/TOF-MS analysis. Surprisingly, masses detected in both 312 fractions were below 600 Da. Since these fractions were collected at the beginning of the 313 elution profile of ultrafiltered olive water (10,000 Da cut off membrane), peptides present in 314 both fractions should have a bigger size. One possible explanation for the unsuccessful 315 detection of peptides is that these compounds were bound to oxidized polyphenols, thus 316 forming high-molecular complexes. MALDI-TOF/TOF-MS has proven to be very efficient 317 for structural analysis of peptides, but limitations in the evaluation of the molecular weight 318 distributions of peptide-polyphenol mixtures are obvious. The successful application of 319 MALDI-TOF/TOF-MS to such complex mixtures is mainly restricted by peptide-polyphenol 320 interactions, and depends on the properties and molecular weight of both the peptide and the 321 polyphenol. The higher the molecular size of the polyphenol, the greater the tendency to form 322 complexes with peptides, and the worse the resolution due to problems with the 323 fragmentation. Mané et al. (2007) found that complexes resulting from interaction between 324 proteins from grape seed and tannins such as β-lactoglobulin, β-casein or myoglobin were not 325 detected by MALDI-TOF-MS. From the results obtained in section 3.4., and 3.5. it is 326 suggested that peptides related to acrylamide formation in olives were covalently bound to 327 polyphenols, thus forming larger complexes. 328 According to the findings of Konno et al. (1999), by enzymatic conversion of 329 oleuropein, a naturally-occurring secoiridoid polyphenol in olives, into a glutaraldehyde-like 330 α,ß-unsaturated highly reactive dialdehyde, proteins are covalently cross-linked. The resultant 331 oleuropein aglycone has been proposed as a cross-linking agent for collagen. Therefore, it can 332 be assumed, that the activated form of oleuropein interacts with olive peptides as the 333 aldehydic component. Furthermore, in the above mentioned study, polyphenol oxidase 334 activity was shown to activate dihydroxyphenolic moieties through the formation of o- 335 quinones to exert protein-binding activities. Briante et al. (2000) and Antunes et al. (2013) 13 336 confirmed that the aglycone form of oleuropein has a strong affinity for nucleophilic binding 337 sites such as amino and thiol groups of proteins, thus forming protein-polyphenol-adducts. 338 339 3.4. Determination of polyphenols by LC-MS 340 341 Polyphenols profile in table olives has been extensively studied. Olive fruits are rich 342 sources of hydroxytyrosol, verbascoside, ligustroside, salidroside, rutin, luteolin 7-glucoside 343 and many other phenolics including secoiridoid derivatives like oleuropein (Ryan et al., 2002; 344 Romero et al, 2004; Cardoso et al., 2005). For the determination of polyphenols in fractions 2 345 and 3 by LC-MS, a PGC column was used. This stationary phase was shown to be suited to 346 separate peptides from phenolics compounds by Desportes, Charpentier, Duteurtre, Maujean 347 and Duchiron (2000) using HPLC-fractionation of small peptides from wine. Surprisingly, 348 despite the positive Folin-Ciocalteu reaction demonstrating the presence of polyphenols in 349 fractions 2 and 3, both fractions exhibited dark coloration providing further evidence of 350 polyphenols being involved in both fractions. However, none of the fragment ions typical of 351 olive polyphenols was detected by ESI-MS. This fact further supported our hypothesis of 352 polyphenols in both fractions being covalently bound to peptides. 353 354 3.5. Adsorptive removal of phenolic compounds from olive water fractions using polymeric 355 resin 356 357 To isolate peptides from fractions 2 and 3, and to confirm the presence of peptide- 358 polyphenol complexes, both fractions were subjected to adsorptive removal of polyphenolics 359 using a polymeric resin. Amberlite XAD 16HP resin has been successfully used by Weisz, 360 Schneider, Schweiggert, Kammerer and Carle (2010) to decolorize sunflower protein extracts. 14 361 They observed initial phenolic contents to be decreased by 86% upon addition of the resin, 362 whereas protein loss was below 5%. 363 From each fraction, two different fractions were obtained: (1) fraction E, a colorless 364 solution containing the compounds not retained on the polymeric adsorber resin, and (2) 365 fraction F, a pigmented solution containing the compounds retained on the resin after their 366 subsequent recovery by elution as explained in section 2.6. In fraction E, the initial phenolic 367 concentrations in fractions 2 and 3 amounting to 0.040 and 0.043 g caffeic acid/100 mL, 368 respectively, were decreased by 85 and 87%, respectively, upon the addition of the resin. 369 These losses were comparable to those reported by Weisz, Schneider, Schweiggert, 370 Kammerer and Carle (2010). When analyzing the phenolic compounds of fraction F from 371 both fractions, the proportion of polyphenols retained on the resin represented 80 and 83% of 372 the initial concentration in fractions 2 and 3, respectively. Regarding peptides, their 373 adsorption to the resin was also found to be high in both fractions, since their initial peptide 374 contents in fractions 2 and 3 (34 and 35 mg peptides/L, respectively) was reduced by 90 and 375 83%, respectively. In contrast, fraction F from fractions 2 and 3 still contained 85 and 72% of 376 the initial peptide content, respectively. Four commercial food-grade adsorbent and three ion 377 exchange resins, including Amberlite XAD 16HP, using different conditions were tested in 378 sunflower extracts by Weisz, Schneider, Schweiggert, Kammerer and Carle (2010), and 379 maximum protein loss was 31% for Amberlite XAD 1180N resin, while protein losses were 380 generally below 5% for most other resins. Therefore, substantial peptides losses in fractions 2 381 and 3 also suggested peptides to form complexes with polyphenols. 382 Fraction E and F from fractions 2 and 3 were subjected to heat treatment (121 ºC for 383 30 min). While only trace amounts of acrylamide were detected in fraction E (containing the 384 compounds not retained on the resin) from fraction 2, acrylamide was not detected in the 385 same solution from fraction 3. However, heating fractions F (containing the compounds 386 retained on the resin after their subsequent recovery by elution) yielded significant amounts of 15 387 acrylamide in both fractions (240 ± 13, and 130 ± 4 µg/L in fractions 2 and 3, respectively). 388 As earlier reported, peptide concentrations in fraction F from fractions 2 and 3 were 85 and 389 72% of the original fraction, respectively. Again, these findings confirmed the role of peptides 390 smaller than 10,000 Da to be the principle precursors of acrylamide formation in heated olives 391 being completely devoid of reducing sugars and free Asn. 392 393 4. Conclusion 394 395 Although the exact mechanism of acrylamide formation in sterilized table olives still 396 remains to be elucidated, the results of the present study confirm small peptides (< 10,000 Da) 397 to be the principal precursors of acrylamide following heat treatment of olives mimicking 398 sterilization (121 ºC, 30 min). Therefore, in the complete absence of reducing sugars and free 399 Asn, after removal of low molecular compounds by SPE, olive water from green olives and 400 peptide containing fractions isolated by different methods (ultrafiltration, SEC and adsorption 401 with polymeric resin), respectively, generated significant amounts of acrylamide after heat 402 treatment. Upon heating to 121 ºC for 30 min, the low molecular fractions obtained by SEC 403 containing the highest concentrations of peptides, yielded the highest amounts of acrylamide. 404 Taking together the results of this study, covalent binding of olive polyphenols to 405 peptides is assumed to be responsible for acrylamide formation. As previously discussed, 406 different authors (Konno et al., 1999; Briante et al., 2000; Antunes et al., 2013) have 407 demonstrated adduct formation of enzymatically activated oleuropein and proteins. 408 Oleuropein hydrolyzed by β-glucosidase had even stronger protein-crosslinking and lysine- 409 alkylating activities than glutaraldehyde. In our previous report (Casado, Montaño, Spitzner & 410 Carle, 2013), formation of acrylamide from Ala, Asp and Met containing model peptides at 411 200°C for 180 min was abundant without the involvement of any carbonyl component. 412 Moreover, acrylamide was not formed following mild heating of the same model peptides at 16 413 121°C for 30 min, representing typical sterilization conditions for black ripe olives. Although 414 the addition of some genuine phenolic compounds present in olives at different levels, e. g. 415 hydroxytyrosol and 3,4-dihydroxyphenyl glycol, has been reported to insignificantly affect 416 acrylamide formation in heated olive water (Casado, Sánchez & Montaño, 2010), our findings 417 suggest that peptides need to be activated, e. g. by the formation of adducts with reactive 418 polyphenols (i. e. oleuropein aglycone and o-quinones, respectively) to form acrylamide in 419 table olives following sterilization without the involvement of free Asn and reducing sugars, 420 respectively. Our assumption is supported by our previous investigations of synthetic peptides 421 which produced acrylamide only when heated to 200°C without the involvement of carbonyl 422 components, whereas acrylamide formation was observed under less harsh heat conditions 423 (121°C) in the presence of the reactive polyphenols, thus suggesting activation by the 424 carbonyl adduct. Further investigations are still required to unravel the activating role of 425 polyphenols by the aldehydic component in the acrylamide formation mechanism of table 426 olives. 427 428 Acknowledgements 429 430 This work was supported in part by the European Union (FEDER funds) and the 431 Spanish government through Project AGL 2010-19178. The Spanish government is also 432 thanked for the fellowship of the first author. 433 434 References 435 436 Amrein, T. M., Andres, L., Escher, F., & Amadò, R. (2007). Occurrence of acrylamide in 437 selected foods and mitigation options. Food Additives and Contaminants, 24, 13-25. 17 438 Antunes, A. P. M., Attenburrow, G., Covington, A. D., & Ding, J. (2013). Utilisation of 439 oleuropein as crosslinking agent in collagenic films. Journal of Leather Science, 2, 17-23. 440 Bradford, M. M. (1976). A rapid sensitive method for the quantification of microgram 441 quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 442 72, 248-254. 443 Briante, R., La Cara, F., Febbraio, F., Barone, R., Piccialli, G., Carolla, R., Mainolfi, P., Da 444 Napoli, L., Patumi, M., Fontanazza, G., & Nucci, R. (2000). Hydrolysis of oleuropein by 445 recombinant β-glycosidase from hyperthermophilic archaeon Sulfolobus solfataricus 446 immobilised on chitosan matrix. Journal of Biotechnology, 77, 275-286. 447 Cardoso, S. M., Guyot, S., Marnet, N., Lopes-da-Silva, J. A., Renard, C. M. G. C., & 448 Coimbra, M. A. (2005). Characterisation of phenolic extracts from olive pulp and olive 449 pomace by electrospray mass spectrometry. Journal of the Science of Food and Agriculture, 450 85, 21-32. 451 Casado, F. J., & Montaño, A. (2008). Influence of processing conditions on acrylamide 452 content in black ripe olives. Journal of Agricultural and Food Chemistry, 56, 2021-2027. 453 Casado, F. J., Sánchez, A. H., & Montaño, A. (2010). Reduction of acrylamide content of ripe 454 olives by selected additives. Food Chemistry, 119, 161-166. 455 Casado, F. J., Montaño, A., Spitzner, D., & Carle, R. (2013). Investigation into acrylamide 456 precursors in sterilized table olives: Evidences of a peptic fraction being responsible for 457 acrylamide formation. Food Chemistry, 141, 1158-1165. 458 Desportes, C., Charpentier, M., Duteurtre, B., Maujean, A., & Duchiron, F. (2000). Liquid 459 chromatographic fractionation of small peptides from wine. Journal of Chromatography A, 460 893, 281-291. 461 Friedman, M. (2003). Chemistry, biochemistry, and safety of acrylamide. A review. Journal 462 of Agricultural and Food Chemistry, 51, 4504-4526. 18 463 FDA (US Food and Drug 464 Individual Food Products. US Department of Health and Human Services. Center for Food 465 Safety 466 http://www.fda.gov/Food/FoodSafety/FoodContaminantsAdulteration/ChemicalContaminants 467 /Acrylamide/ucm053549.htm 468 Gökmen, V., & Palakzaglu, T. (2008). Acrylamide formation in foods during thermal 469 processing with a focus on frying. Food and Bioprocess Technology, 1, 35-42. 470 International Agency for Research on Cancer (1994). IARC Monographs on the evaluation of 471 carcinogenic risks to humans: some industrial chemicals. Vol. 60. Acrylamide. Lyon, France: 472 IARC 1994, pp 389-433. 473 Kaiser, A., Carle, R., & Kammerer, D. R. (2013). Effects of blanching on polyphenol stability 474 of innovative paste-like parsley (Petroselinum crispum (Mill.) Nym ex A. W. Hill) and 475 marjoram (Origanum majorana L.) products. Food Chemistry, 138, 1648-1656. 476 Konno, K., Hirayama, C., Yasui, H., & Nakamura, M. (1999). Enzymatic activation of 477 oleuropein: A protein crosslinker used as a chemical defense in the privet tree. Procedure of 478 the National Academy of Sciences, 96, 9159-9164. 479 Mané, C., Sommerer, N., Yalcin, T., Cheynier, V., Cole, R. B., & Fulcrand, H. (2007). 480 Assessment of the molecular weight distribution of tannin fractions through MALDI-TOF MS 481 analysis of protein-tannin complexes. Analytical Chemistry, 79, 2239-2248. 482 Mottram, D. S., Wedzicha, B. L., & Dodson, A. T. (2002). Acrylamide is formed in the 483 Maillard reaction. Nature, 419, 448-449. 484 Romero, C., Brenes, M., Yousfi, K., García, P., García, A., & Garrido, A. (2004). Effect of 485 cultivar and processing method on the contents of polyphenols in table olives. Journal of 486 Agricultural and Food Chemistry, 52, 479-484. and Administration) (2006). Survey Data on Acrylamide in Food: Nutrition, available 19 online at 487 Ryan, D., Antolovich, M., Herlt, T., Prenzler, P. D., Lavee, S., & Robards, K. (2002). 488 Identification of phenolic compounds in tissues of novel olive cultivar Hardy’s Mammoth. 489 Journal of Agricultural and Food Chemistry, 50, 6716-6724. 490 Singleton, V. L., & Rossi, J. A. (1965). Colorimetry of total phenolics with 491 phosphomolybdic-phosphotungstic acid reagent. American Journal of Oenology and 492 Viticulture, 16, 144-158. 493 Stadler, R. H., Blank, I., Varga, N., Robert, F., Hau, J.; Guy, P. A., Robert, M.-C., & 494 Riediker, S. (2002). Acrylamide from Maillard reaction products. Nature, 419, 449-450. 495 Tareke, E., Rydberg, P., Karlsson, P., Eriksson, S., & Tornqvist, M. (2002). Analysis of 496 acrylamide, a carcinogen formed in heated foodstuffs. Journal of Agricultural and Food 497 Chemistry, 50, 4998-5006. 498 Weisz, G. M., Schneider, L., Schweiggert, U., Kammerer, D. R., & Carle, R. (2010). 499 Sustainable sunflower processing – I. Development of a process for the adsorptive 500 decolorization of sunflower [Helianthus annuus L.] protein extracts. Innnovative Food Science 501 and Emerging Technologies, 11, 733-741. 20 Figure captions Figure 1. Scheme for the fractionation of peptides from olive water. Figure 2. Elution profile of the fraction obtained after partial fractionation by SPE (Sep Pak Vac C18 Cartridge) and ultrafiltration (cut off 10,000 Da) of olive water. Toyopearl HW-55F in glass column (600 x 26 mm I.D.). Eluent: 0.3 mol/L ammonium acetate, pH 4.0. Flow: 2 mL/min. Absorbance at 280 nm. (1)-(11) Collected fraction numbers. Figure 3. Polyphenols (g caffeic acid/100 mL x 10-3), peptides (mg/L) and acrylamide (µg/L x 10-1) after heat treatment (121ºC for 30 min) in the 11 different fractions obtained after SPE, ultrafiltration and SEC (Toyoupearl HW55-F, eluent: 0.3 mol/L ammonium acetate, pH 4.0, flow: 2 mL/min) of olive water. Data represent mean values (n = 3). Error bars indicate 95% confidence intervals. 21 Figure(s) Partial fractionation of olive water by SPE Fraction A (H2O) Fraction B (MeOH) Ultrafiltration (Molecular weight cut-off of 10,000 Da) Fraction C (retentate) Analysis for acrylamide after heat treatment (LC-MS/MS) Fraction D (permeate) Analysis for acrylamide after heat treatment (LC-MS/MS) Fractionation of peptides by SEC (Glass column with Toyopearl HW-55F) Analysis of the different fractions (fractions 1–11) Analysis for peptides (Bradford method) Analysis for polyphenols (Folin-Ciocalteu assay) Characterization of peptides (MALDI-TOF/TOF-MS) Analysis for acrylamide after heat treatment (LC-MS/MS) Determination of polyphenols (LC-MS) Adsorptive removal of polyphenols (Amberlite XAD 16 HP) Fraction E (Compounds not retained on the resin) Analysis for peptides and polyphenols Analysis for acrylamide after heat treatment (LC-MS/MS) 22 Fraction F (Compounds retained on the resin) Analysis for peptides and polyphenols Analysis for acrylamide after heat treatment (LC-MS/MS) Figure(s) 1 2 3 4 5 6 7 8 9 10 11 nm Absorbance at 280 Absorbancia a 280nm 350 mV 80 120 160 200 240 80 160 240 320 400 23 280 480 min mL Figure(s) Polyphenols Peptides Acrylamide Fraction 24