Chapter 6 Relevant Information and Decision Making: Production Decisions

advertisement

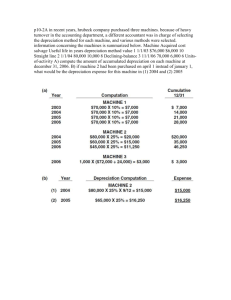

Chapter 6 Relevant Information and Decision Making: Production Decisions 6-1 Learning Objective 1 Use opportunity cost to analyze the income effects of a given alternative. 6-2 Costs An opportunity cost is the maximum available contribution to profit forgone (or passed up) by using limited resources for a particular purpose. An outlay cost requires a cash disbursement. 6-3 Costs Differential cost and incremental cost are defined as the difference in total cost between two alternatives. 6-4 Learning Objective 2 Decide whether to make or buy certain parts or products. 6-5 Make-or-Buy Decisions The basic make-or-buy question is whether a company should make its own parts to be used in its products or buy them from vendors. 6-6 Make-or-Buy Decisions Qualitative Factors: Control quality Protect long-term relationships with suppliers Quantitative Factors: Idle facilities or capacity 6-7 Make-or-Buy Example GE Company Cost of Making Part N900: Total Cost for Cost 20,000 Units per Unit Direct material $ 20,000 $ 1 Direct labor 80,000 4 Variable overhead 40,000 2 Fixed overhead 80,000 4 Total costs $220,000 $11 6-8 Make-or-Buy Example Another manufacturer offers to sell GE the same part for $10. The essential question is the difference in expected future costs between the alternatives. Should GE make or buy the part? 6-9 Make-or-Buy Example If the $4 fixed overhead per unit consists of costs that will continue regardless of the decision, the entire $4 becomes irrelevant. If $20,000 of the fixed costs will be eliminated if the parts are bought instead of made, the fixed costs that may be avoided in the future are relevant. 6 - 10 Relevant Cost Comparison Make Total Per Unit Purchase cost Direct material Direct labor Variable overhead Fixed OH avoided by not making Total relevant costs Difference in favor of making Buy Total Per Unit $200,000 $10 $ 20,000 $ 1 80,000 4 40,000 2 20,000 10 $160,000 $ 8 0 $200,000 0 $10 $ 40,000 $ 2 6 - 11 Learning Objective 3 Decide whether a joint product should be processed beyond the split-off point. 6 - 12 Joint Products Joint products have relatively significant sales values. They are not separately identifiable as individual products until their split-off point. The split-off point is that juncture of manufacturing where the joint products become individually identifiable. 6 - 13 Joint Products Separable costs are any costs beyond the split-off point. Joint costs are the costs of manufacturing joint products before the split-off point. 6 - 14 Illustration of Joint Costs Suppose Dow Chemical Company produces two chemical products, X and Y, as a result of a particular joint process. The joint processing cost is $100,000. Both products are sold to the petroleum industry to be used as ingredients of gasoline. 6 - 15 Illustration of Joint Costs 1 million liters of X at a selling price of $.09 = $90,000 Joint-processing cost is $100,000 500,000 liters of Y at a selling price of $.06 = $30,000 Total sales value at split-off is $120,000 Split-off point 6 - 16 Illustration of Sell or Process Further Suppose the 500,000 liters of Y can be processed further and sold to the plastics industry as product YA. The additional processing cost would be $.08 per liter for manufacturing and distribution, a total of $40,000. The net sales price of YA would be $.16 per liter, a total of $80,000. 6 - 17 Illustration of Sell or Process Further Sell at Split-off as Y Revenue $30,000 Separable costs beyond split-off @ $.08 – Income effects $30,000 Process Further and Sell as YA Difference $80,000 $50,000 40,000 $40,000 40,000 $10,000 6 - 18 Learning Objective 4 Identify irrelevant information in disposal of obsolete inventory and equipment replacement decisions. 6 - 19 Irrelevance of Past Costs 1 2 Two examples of past costs that we can consider, to see why they are irrelevant to decisions, are: The cost of obsolete inventory The book value of old equipment 6 - 20 Example of Irrelevance of Obsolete Inventory Suppose General Dynamics has 100 obsolete aircraft parts in its inventory. The original manufacturing cost of these parts was $100,000. 6 - 21 Example of Irrelevance of Obsolete Inventory General Dynamics can... 1 remachine the parts for $30,000 and then sell them for $50,000, or 2 scrap them for $5,000. Which should it do? 6 - 22 Example of Irrelevance of Obsolete Inventory Remachine Scrap Difference Expected future revenue $ 50,000 $ 5,000 $45,000 Expected future costs 30,000 0 30,000 Relevant excess of revenue over costs $ 20,000 $ 5,000 $15,000 Accumulated historical inventory cost* 100,000 100,000 0 Net loss on project $(80,000) $ (95,000) $15,000 *Irrelevant because it is unaffected by the decision. 6 - 23 Irrelevance of Book Value of Old Equipment The book value of equipment is not a relevant consideration in deciding whether to replace the equipment. Why? Because it is a past, not a future cost. 6 - 24 Irrelevance of Book Value of Old Equipment Depreciation is the periodic allocation of the cost of equipment. The equipment’s book value (or net book value) is the original cost less accumulated depreciation. 6 - 25 Example of Book Value Computation Suppose a $10,000 machine with a 10-year life has depreciation of $1,000 per year. What is the book value at the end of 6 years? Original cost $10,000 Accumulated depreciation (6 × $1,000) 6,000 Book value $ 4,000 6 - 26 Keep or Replace an Old Machine? Old Machine Original cost $10,000 Useful life in years 10 Current age in years 6 Useful life remaining in years 4 Accumulated depreciation $ 6,000 Book value $ 4,000 Disposal value (in cash) now $ 2,500 Disposal value in 4 years 0 Annual cash operating costs $ 5,000 Replacement Machine $8,000 4 0 4 0 N/A N/A 0 $3,000 6 - 27 Keep or Replace an Old Machine? What is a sunk cost? A sunk cost is a cost that has already been incurred and, therefore, is irrelevant to the decision-making process. 6 - 28 Relevance of Equipment Data 1 2 3 4 In deciding whether to replace or keep existing equipment, we must consider the relevance of four commonly encountered items: Book value of old equipment Disposal value of old equipment Gain or loss on disposal Cost of new equipment 6 - 29 Book Value of Old Equipment The book value of old equipment is irrelevant because it is a past (historical) cost. Therefore, depreciation on old equipment is irrelevant. 6 - 30 Disposal Value of Old Equipment The disposal value of old equipment is relevant (ordinarily) because it is an expected future inflow that usually differs among alternatives. 6 - 31 Gain or Loss on Disposal This is the difference between book value and disposal value. It is therefore a meaningless combination of irrelevant (book value) and relevant items (disposal value). It is best to think of each separately. 6 - 32 Cost of New Equipment The cost of the new equipment is relevant because it is an expected future outflow that will differ among alternatives. Therefore depreciation on new equipment is relevant. 6 - 33 Comparative Analysis of the Two Alternatives Four Years Together Keep Replace Difference $20,000 $12,000 $ 8,000 Cash operating costs Old equipment (book value) depreciation, or 4,000 – – lump-sum write-off 4,000 – Disposal value – (2,500) 2,500 New machine acquisition cost – 8,000 (8,000) Total costs $24,000 $21,500 $ 2,500 6 - 34 Learning Objective 5 Explain how unit costs can be misleading. 6 - 35 Beware of Unit Costs 1 2 There are two major ways to go wrong when using unit costs in decision making: The inclusion of irrelevant costs Comparisons of unit costs not computed on the same volume basis 6 - 36 Example of Volume Basis Decision Assume that a new $100,000 machine with a five-year life can produce 100,000 units a year at a variable cost of $1 per unit, as opposed to a variable cost per unit of $1.50 with an old machine. Is the new machine a worthwhile acquisition? 6 - 37 Example of Volume Basis Decision Units Variable cost per unit Variable costs Straight-line depreciation Total relevant costs Unit relevant costs Old Machine 100,000 $1.50 $150,000 0 $150,000 $1.50 New Machine 100,000 $1.00 $100,000 20,000 $120,000 $1.20 6 - 38 Example of Volume Basis Decision It appears that the new machine will reduce costs by $.30 per unit. However, if the expected volume is only 30,000 units per year, the unit costs change in favor of the old machine. 6 - 39 Example of Volume Basis Decision Units Variable cost per unit Variable costs Straight-line depreciation Total relevant costs Unit relevant costs Old Machine 30,000 $1.50 $45,000 0 $45,000 $1.50 New Machine 30,000 $1.00 $30,000 20,000 $50,000 $1.6667 6 - 40 Learning Objective 6 Discuss how performance measures can affect decision making. 6 - 41 Performance Measures Can Affect Decision Making To motivate managers to make the right choices, the method used to evaluate performance should be consistent with the decision model. 6 - 42 Example of Affect on Decision Making Consider the replacement decision, discussed earlier, where replacing the machine had a $2,500 advantage over keeping it. Because performance is often measured by accounting income, consider the accounting income in the first year after replacement compared with that in years 2, 3, and 4. 6 - 43 Example of Affect on Decision Making Year 1 Keep Replace Cash operating costs Depreciation Loss on disposal ($4,000 – $2,500) Total charges against revenue Years 2, 3, and 4 Keep Replace $5,000 1,000 $3,000 2,000 $5,000 1,000 $3,000 2,000 0 $1,500 0 0 $6,000 $6,500 $6,000 $5,000 6 - 44 Example of Affect on Decision Making If the machine is kept rather than replaced, first-year costs will be $500 lower ($6,500 – $6,000), and first-year income will be $500 higher. 6 - 45 Learning Objective 7 Construct absorption and contribution format income statements and identify which is better for decision making. 6 - 46 Absorption Approach The absorption approach is a costing approach that considers all factory overhead (both variable and fixed) to be product (inventoriable) costs. Factory overhead becomes an expense in the form of manufacturing cost of goods sold only as sales occur. 6 - 47 Contribution Approach In contrast, the contribution approach is used by many companies for internal (management accounting) reporting. It emphasizes the distinction between variable and fixed costs. The contribution approach is not allowed for external financial reporting. 6 - 48 Comparing Contribution and Absorption Approaches Manufacturing costs Nonmanufacturing costs Variable costs A. Variable manufacturing costs B. Variable nonmanufacturing costs Fixed costs C. Fixed manufacturing costs D. Fixed nonmanufacturing costs 6 - 49 End of Chapter 6 6 - 50