Cellular Manufacturing- Tiffany Dundon

advertisement

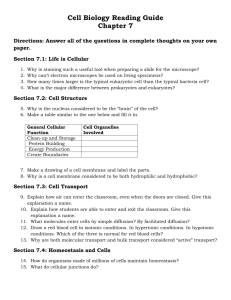

Cellular Manufacturing Tiffany Dundon Boise State University What will be Covered • • • • • • • • Definition Brainstorming Nuts and Bolts Reported Benefits of Cellular Manufacturing How It Works Examples of Cellular Manufacturing An Exercise Conclusion Cellular Manufacturing (CM) Defined “Cellular Manufacturing organizes the entire process for similar products into a group of team members, includes all the necessary equipment and is known as a "Cell". Merryman, Wes. Cellular Manufacturing.Online. Internet. Available at http://www.ciras.iastate.edu/CIRASnews/cellular.html Cellular Manufacturing Defined “…The cells are arranged to easily facilitate all operations. Parts are handed off from operation to operation eliminating setups and unnecessary costs between operations.” Merryman, Wes. Cellular Manufacturing.Online. Internet. Available at http://www.ciras.iastate.edu/CIRASnews/cellular.html Brainstorming • Brainstorm some ideas about cellular manufacturing • How can this tool be used in your organization? Nuts and Bolts • Elimination of wastes by linking steps – Waste is any resource not adding value to the product being manufactured • In a cell, most work stations are close together so that little or no time is required to move parts Nuts and Bolts • Cell teams are cross trained in cell operations – – – – Continuous improvement Reduce lead times Remove waste Improve quality • Product flow is more visible – Easier control Nuts and Bolts • Primary purpose: – Reduce cycle time – Reduce inventories • Other benefits include: – – – – Space reduction Quality improvement Labor cost reduction Improved machine utilization Nuts and Bolts • Human resource issues: – Proper training for operators – Cross functional training – Team building training for operators Nuts and Bolts • Human Resource issues: – Supervisors become coaches – Compensation (incentives) – Initial resistance of CM – Cells need support Reported Benefits of CM • Production and Quality Control Cost 80% • Setup Time 69% • Throughput time • Overdue orders 70% 82% Reported Benefits of CM • Raw Materials Inventory • Finished Goods Inventory 42% 60% • Employees Output per unit time 33% Kok, Alvin Lim Hui. Time Based Manufacturing. Journal of Operations Management. 7 July 1999 How it Works • Members of the plant team need to be involved in the changes • Other functions need to be changed: – Production planning and control – Purchasing – Cost accounting How it works • Where do you begin? • First, define the “cells” by the following criteria: – – – – Processes required Part numbers and attributes Market segments / customers Degree of automation How it Works • Team selection is crucial – Identify important skills needed such as teamwork and leadership skills – Create a process map – Develop a checklist for selecting members How it Works • Match skills to tasks – Create a matrix to define who is best qualified for each task • Develop team trust and motivation – Manage team morale – Encourage teamwork Real World Example John Deere • Integrated welding work cells • Utilizes robotic welding processes – Faster weld times – Consistent welds – Endurance Real World Example John Deere • Major benefits of CM: – – – – Switching of welds is simple Factory has maximum flexibility Delivers higher quality Faster delivery Real World Example Inscape • Production divided into highly specialized “cells” – Each cell contains equipment, technology and people – Each cell can make a wide variety of family products Real World Example Inscape • Major benefits of CM: – – – – Consistently high quality Flexibility for customers Quick changes in size and style Mass customization A Short Exercise • How is implementing CM useful in your organization? • How will you define cells? Form teams? Motivate and develop trust? Change functions? Change the plant layout? Summary • CM: based on a group of different processes located in close proximity to manufacture similar products • You must first define the “cells” and then develop a team Summary • Training and support are key elements • Many reported benefits to switching your organization to cellular manufacturing – Reduce inventories, and more References John Deere. State-of-the-art Robotic Welding. Online. Internet. 3 May 2002. Available at http://customer.com/en_za/ag/service/roboticwelding.html Inscape Solutions. Cellular Manufacturing. Online. Internet. 29 April 2002. Available at http://www.inscapesolutions.com/products/cellular.html Kok, Alvin Lim Hui. Time Based Manufacturing. Journal of Operations Management. 7 July 1999 Merryman, Wes. Cellular Manufacturing.Online. Internet. 15 April 2002. Available at http://www.ciras.iastate.edu/CIRASnews/cellular.html Patel, Jay. Cellular Manufacturing. Online. Internet. 10 April 2002. Available at http://qpsconsulting.com?cellularmanufacturing.htm