NZQA registered unit standard 21178 version 3 Page 1 of 3

advertisement

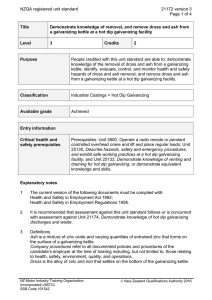

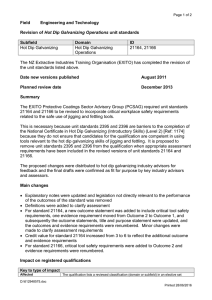

NZQA registered unit standard 21178 version 3 Page 1 of 3 Title Recover an object from a preparation tank and a galvanizing kettle Level 3 Credits 3 Purpose People credited with this unit standard are, at a hot dip galvanizing facility, able to: identify and evaluate health and safety hazards of recovering an object from preparation tanks and galvanizing kettle, and describe control and compliance methods; develop a recovery plan for the recovery of an object from a preparation tank and from a galvanizing kettle; and recover an object from a preparation tank and from a galvanizing kettle. Classification Industrial Coatings > Hot Dip Galvanizing Available grade Achieved Entry information Critical health and safety prerequisites Prerequisites: Unit 3800, Operate a radio remote or pendant controlled overhead crane and lift and place regular loads; Unit 25130, Describe hazards, safety and emergency procedures, and exhibit safe working practices at a hot dip galvanizing facility; or demonstrate equivalent knowledge and skills. Explanatory notes 1 The current version of the following documents must be complied with: Health and Safety in Employment Act 1992 (HSE); Health and Safety in Employment Regulations 1995; AS/NZS 4680:2006 Hot-dip galvanized (zinc) coatings on fabricated ferrous articles, available at http://www.standards.co.nz. 2 Personal protective equipment (PPE) must be used throughout operations in accordance with company procedures. 3 Definition Company procedures refer to all documented policies and procedures of the candidate’s employer at the time of training including, but not limited to, those relating to health, safety, environment, quality, and operations. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 21178 version 3 Page 2 of 3 Outcomes and evidence requirements Outcome 1 Identify and evaluate health and safety hazards of recovering an object from preparation tanks and galvanizing kettle, and describe control and compliance methods at a hot dip galvanizing facility. hazards include but are not limited to – radiant heat, fumes, physical force, hot equipment, overhead cranes, molten zinc. Range Evidence requirements 1.1 Health and safety hazards are identified and evaluated in terms of HSE Act and company procedures. 1.2 Hazard control and compliance methods are described in terms of HSE Act and company procedures. Outcome 2 Develop a recovery plan for the recovery of an object from a preparation tank and from a galvanizing kettle at a hot dip galvanizing facility. Evidence requirements 2.1 A recovery plan is developed to recover an object from a preparation tank and from a galvanizing kettle at a hot dip galvanizing facility in accordance with company procedures. Range recover plans must include – tools, staffing requirements, method required to achieve safe recovery of the object. Outcome 3 Recover an object from a preparation tank at a hot dip galvanizing facility. Evidence requirements 3.1 Health and safety hazards are controlled and monitored during the recovery in accordance with the HSE Act and company procedures. 3.2 The object is removed from a preparation tank in accordance with the recovery plan and company procedures. Outcome 4 Recover an object from a galvanizing kettle at a hot dip galvanizing facility. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 21178 version 3 Page 3 of 3 Evidence requirements 4.1 Reasons for recovery from a galvanizing kettle are described in terms of dross creation and effect of zinc on the object. 4.2 Health and safety hazards are controlled and monitored during the recovery in accordance with the HSE Act and company procedures. 4.3 The object is removed from a galvanizing kettle in accordance with the recovery plan and company procedures. Range tools are heated and dry before use. Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 21 October 2004 31 December 2016 Review 2 23 January 2009 31 December 2016 Review 3 16 April 2015 N/A Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016