NZQA unit standard 17534 version 4

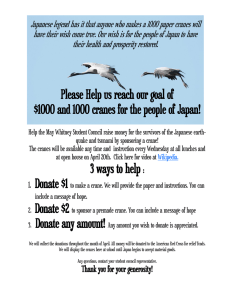

advertisement

NZQA Expiring unit standard 17534 version 4 Page 1 of 4 Title Demonstrate knowledge of and operate gantry crane in an abrasive blasting and protective coating workshop Level 3 Credits 5 Purpose People credited with this unit standard are able to: demonstrate knowledge of gantry cranes and lifting equipment used in an abrasive blasting and protective coating workshop; prepare for operation of gantry cranes; operate crane to lift, travel, unload, and place loads, in an abrasive blasting and protective coating workshop. Classification Blaster Coating > Blaster Coating Operations Available grade Achieved Entry information Critical health and safety prerequisites Unit 17547, Demonstrate knowledge of health and safety in abrasive blasting and protective coating environments, or demonstrate equivalent knowledge and skills. Explanatory notes 1 Performance of the outcomes of this unit standard must comply with the following enactments, codes, and regulations: the Health and Safety in Employment (HSE) Act 1992; Health and Safety in Employment (Pressure Equipment, Cranes and Passenger Ropeways) Regulations 1999; A Guide to the Health and Safety in Employment Act 1992 (2nd Ed) (Wellington: Department of Labour 2003); and Approved code of practice for cranes (the Code) (Wellington: Occupational Safety and Health Service, Department of Labour, 2001). 2 Company procedures refer to documented methods for performing work activities and include health and safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17534 version 4 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Describe gantry cranes and lifting equipment used in an abrasive blasting and protective coating workshop. Evidence requirements 1.1 Components of gantry cranes are identified and described in terms of their functions. Range includes but is not limited to – operator controls, limit-warning devices, slings, hooks, grabs, magnets. 1.2 Lifting equipment terminology is used in accordance with manufacturer’s instructions and company procedures. 1.3 Inspection requirements of cranes are described in terms of the HSE Act and the Code. 1.4 Crane signals are demonstrated in accordance with company procedures. Range includes but is not limited to – stop, hoist, lower, traverse in, traverse out, travel left, travel right. 1.5 Maintenance of gantry cranes is described in terms of requirements for cranes operated in an abrasive blasting and protective coating workshop. 1.6 Operational procedures are described in terms of using gantry cranes in an abrasive blasting and protective coating workshop. Outcome 2 Prepare for operation of gantry cranes in an abrasive blasting and protective coating workshop. Evidence requirements 2.1 Load is confirmed as being within safe working capacity of crane in accordance with current certificate of fitness. 2.2 Hazards are identified and action taken in accordance with the HSE Act and company procedures. 2.3 Pre-operational checks are carried out and adjustments made in accordance with manufacturers’ instructions. 2.4 Travel route is clear and crane use is communicated to persons in the workshop in accordance with safety plan. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17534 version 4 Page 3 of 4 Outcome 3 Operate crane to lift, travel, unload, and place loads in an abrasive blasting and protective coating workshop. Range loads common to abrasive blasting workshops may include but are not limited to – beams, roof trusses, pipes, tanks, chassis. Evidence requirements 3.1 Load is raised and checked in accordance with company procedures. 3.2 Load is moved and unloaded in accordance with manufacturer’s instructions and company procedures. 3.3 Load is placed on transporting vehicle in accordance with manufacturer’s instructions and company procedures. 3.4 Dogman and signals are clearly visible during crane operation. 3.5 Procedures for end of operation are demonstrated in accordance with manufacturer’s instructions. Range crane motor turned off, controls locked. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 28 August 2000 31 December 2017 Review 2 20 November 2006 31 December 2017 Review 3 18 October 2012 31 December 2017 Rollover 4 17 October 2013 31 December 2017 Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17534 version 4 Page 4 of 4 Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016