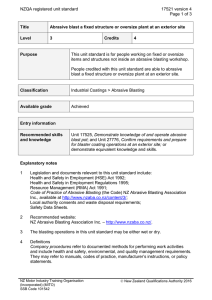

NZQA unit standard 17535 version 5

advertisement

NZQA Expiring unit standard 17535 version 5 Page 1 of 5 Title Supervise safety on an abrasive blasting and protective coating site Level 4 Credits 20 Purpose People credited with this unit standard are able to demonstrate knowledge of: requirements of the Health and Safety in Employment Act as they apply to abrasive blasting and protective coating environments, occupational safety and health requirements, and other Acts that affect abrasive blasting and protective coating operations; demonstrate leadership in matters of safety; and manage hazards in an abrasive blasting and protective coating workplace. Classification Blaster Coating > Blaster Coating Operations Available grade Achieved Entry information Critical health and safety prerequisites Unit 17547, Demonstrate knowledge of health and safety in abrasive blasting and protective coating environments, or demonstrate equivalent knowledge and skills. Explanatory notes 1 Performance of the outcomes of this unit standard must comply with the following enactments, codes, and guidelines: the Health and Safety in Employment (HSE) Act 1992; Health and Safety in Employment Regulations 1995; Resource Management Act 1991; and Practical Guidelines for the Safe Use of Organic Solvents (Wellington: Occupational Safety and Health Service, Department of Labour, 1992). 2 Other enactments and regulations relevant to this unit standard may include but are not limited to: Injury Prevention, Rehabilitation, and Compensation Act 2001; Employment Relations Act 2000; Building Act 2004; Hazardous Substances and New Organisms Act 1996; Land Transport Act 1998; and Spray Coating Regulations 1962. 3 The Environment Risk Management Authority (ERMA) is responsible for assessing and approving hazardous substances and, where appropriate, setting controls on the way the substance is used. Any questions relating to the provisions for hazardous substances should be directed to ERMA New Zealand telephone 04 916 2426 or EXITO telephone 03 964 4710. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 4 17535 version 5 Page 2 of 5 Company procedures refer to documented methods for performing work activities and include the health and safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, manufacturer’s instructions, or policy statements. Site safety plan refers to the documented safety plan for the site which is required by law to ensure compliance with the requirements of the Health and Safety in Employment Act 1992 and its subsequent amendments. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of requirements of the HSE Act as they apply to abrasive blasting and protective coating environments. Evidence requirements 1.1 Supervisor’s responsibilities are described in terms of contract, common, and statute law. 1.2 Individual responsibilities are described in terms of obligations under the HSE Act. Range individual responsibilities of – supervisor, employee, employer, person who controls place of work. 1.3 Requirements of the HSE Act are described in terms of accident report and register. 1.4 Terminology is explained and/or used in accordance with the HSE Act. Range potential hazard, hazard, significant hazard, serious harm, eliminate, isolate, minimise, protect. Outcome 2 Demonstrate knowledge of occupational safety and health (OSH) requirements for abrasive blasting and protective coating. Evidence requirements 2.1 Role of OSH inspectors is described in accordance with the HSE Act. 2.2 OSH inspections are described in terms of rights of employers and employees. 2.3 Offences related to abrasive blasting and protective coating operations are described in terms of the HSE regulations. 2.4 OSH notices are described in terms of their types. Range improvement, prohibition, suspension. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17535 version 5 Page 3 of 5 2.5 Occupational health is described in terms of physical, chemical, and biological hazards. 2.6 Occupational health is described in terms of digestion, inhalation, absorption, noise, lighting. 2.7 Occupational health is described in terms of occupational exposure limits. Outcome 3 Demonstrate knowledge of other Acts that affect abrasive blasting and protective coating operations. Evidence requirements 3.1 Employment Relations Act is described in terms of types of contract and procedures for personal grievances. 3.2 Resource Management Act is described in terms of powers of local authorities and resource consents. 3.3 Injury Prevention, Rehabilitation, and Compensation Act 2001 is described in terms of principles of rehabilitation. 3.4 Regulations specifically affecting abrasive blasting and protective coating operations are identified and described in terms of accident recording and notification of serious harm. Range 3.5 General regulations affecting abrasive blasting and protective coating operations are described in terms of safety requirements. Range 3.6 regulations include but are not limited to – abrasive blasting, hazardous substances, spray protective coating, working at height. regulations include – general workplace, machinery, construction. Other legislation that may affect abrasive blasting and protective coating operations is described in terms of its implications for safety in abrasive blasting and protective coating operations. Range includes but is not limited to – Hazardous Substances and New Organisms Act 1996, Land Transport Act 1998. Outcome 4 Demonstrate leadership in matters of safety in an abrasive blasting and protective coating operation. Evidence requirements 4.1 Actions resulting from risk assessment are communicated to employer and employees in accordance with site safety plan. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 4.2 17535 version 5 Page 4 of 5 Safe practices are reinforced and employees are motivated to observe safety requirements and report hazards and near misses. Range may include but is not limited to – toolbox meetings. 4.3 Safety notices are displayed in workplace in accordance with site safety plan. 4.4 Site safety meeting is chaired and recorded in accordance with site safety plan. 4.5 Effective time management is demonstrated in terms of prioritising safety tasks, managing interruptions and diversions, delegating, and not delaying tasks. 4.6 Unsafe practices are eliminated in accordance with company procedures. Range may include but is not limited to – retraining, reprimand, warning, suspension. Outcome 5 Manage hazards in an abrasive blasting and protective coating workplace. Evidence requirements 5.1 Hazard and health risk assessment is completed in accordance with the HSE regulations. Range includes but is not limited to – review of initial assessment and periodic health assessment of workers required to wear respiratory protective equipment. 5.2 Hazards are controlled in terms of elimination, isolation, minimisation, and protection. 5.3 An incident report is completed in accordance with the HSE Act and company procedures. 5.4 Safety training of employees is implemented and documented in accordance with company procedures. Range includes but is not limited to – induction, personal protective equipment, flammable substances, abrasive blasting, working at height. 5.5 Occupational exposure limits are measured and controlled in accordance with the HSE regulations. 5.6 Worksafe audit is conducted and recorded in accordance with company procedures. 5.7 Environmental hazards and health risks are controlled in accordance with the HSE regulations and Resource Management Act 1991. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17535 version 5 Page 5 of 5 This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 28 August 2000 31 December 2017 Revision 2 22 May 2001 31 December 2017 Review 3 20 November 2006 31 December 2017 Review 4 18 October 2012 31 December 2017 Rollover 5 17 October 2013 31 December 2017 Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. NZ Extractive Industries Training Organisation SSB Code 101815 New Zealand Qualifications Authority 2016