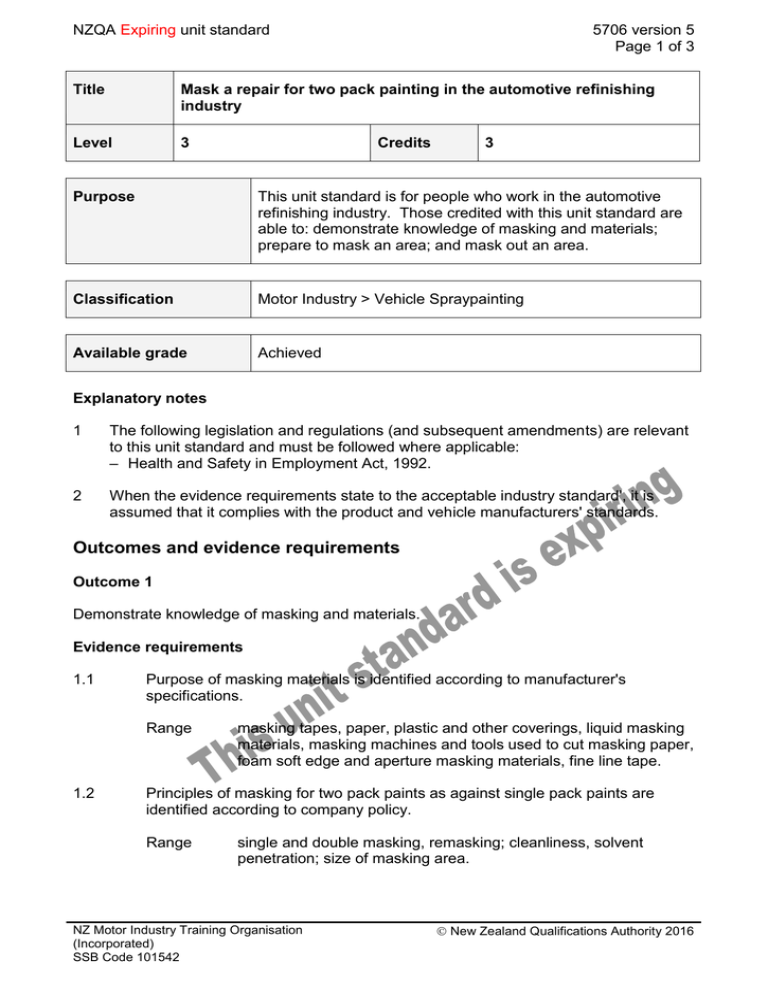

NZQA unit standard 5706 version 5

advertisement

NZQA Expiring unit standard 5706 version 5 Page 1 of 3 Title Mask a repair for two pack painting in the automotive refinishing industry Level 3 Credits 3 Purpose This unit standard is for people who work in the automotive refinishing industry. Those credited with this unit standard are able to: demonstrate knowledge of masking and materials; prepare to mask an area; and mask out an area. Classification Motor Industry > Vehicle Spraypainting Available grade Achieved Explanatory notes 1 The following legislation and regulations (and subsequent amendments) are relevant to this unit standard and must be followed where applicable: – Health and Safety in Employment Act, 1992. 2 When the evidence requirements state to the acceptable industry standard', it is assumed that it complies with the product and vehicle manufacturers' standards. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of masking and materials. Evidence requirements 1.1 Purpose of masking materials is identified according to manufacturer's specifications. Range 1.2 masking tapes, paper, plastic and other coverings, liquid masking materials, masking machines and tools used to cut masking paper, foam soft edge and aperture masking materials, fine line tape. Principles of masking for two pack paints as against single pack paints are identified according to company policy. Range single and double masking, remasking; cleanliness, solvent penetration; size of masking area. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 1.3 5706 version 5 Page 2 of 3 Masking techniques are identified according to company policy. Range two pack masking, single pack masking, soft edge masking, masking stripes (internal, external masking). Outcome 2 Prepare to mask an area. Evidence requirements 2.1 Area to be masked is clean according to tape manufacturer's instructions and company policy. Range 2.2 no dust, dirt, sanding sludge and moisture, oil, wax, grease, silicone. Materials and tools are identified and used according to manufacturer's specifications and company policy. Range masking tapes, masking paper, plastic or equivalent covering, masking machine, scissors, NT cutter, foam soft edge and aperture masking materials. Outcome 3 Mask out an area. Evidence requirements 3.1 Area to be masked is identified, and masking is carried out according to manufacturer's specifications and company policy. 3.2 No paint or overspray gets on to any part of the vehicle that is not being painted. Range glass, other panels, interior and exterior fittings and trim, wheels and arches. 3.3 No dust from masking gets on freshly applied paintwork. 3.4 Materials and tools are clean and put away after use. 3.5 Safe working practices are carried out throughout the task. Range 3.6 personal safety; safety of other people; vehicle safety; workshop safety; environmental safety; tool, equipment, and machine safety. Work is completed to the acceptable industry standard and in an acceptable industry time. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 5706 version 5 Page 3 of 3 Replacement information This unit standard has been replaced by unit standard 24001, and unit standard 24002. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 29 January 1996 31 December 2016 Review 2 20 December 1998 31 December 2016 Revision 3 16 October 2003 31 December 2016 Review 4 26 November 2007 31 December 2016 Rollover 5 19 November 2010 31 December 2016 Accreditation and Moderation Action Plan (AMAP) reference 0014 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Consent requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016