Monitor, analyse, and respond to deviations in a petrochemical process

advertisement

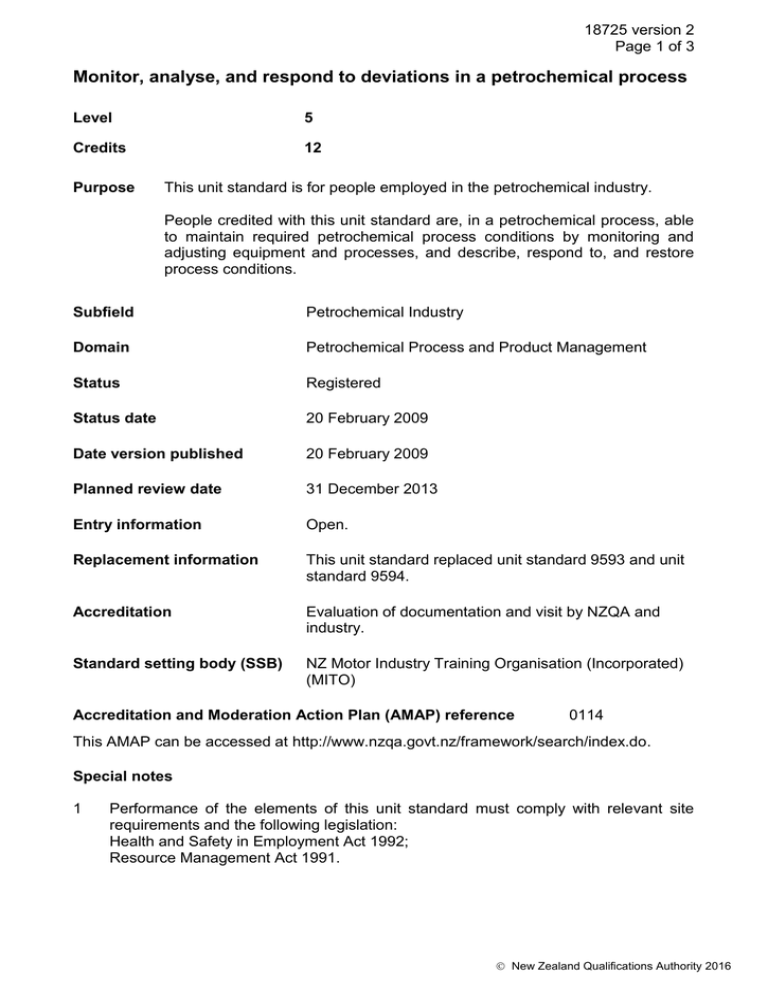

18725 version 2 Page 1 of 3 Monitor, analyse, and respond to deviations in a petrochemical process Level 5 Credits 12 Purpose This unit standard is for people employed in the petrochemical industry. People credited with this unit standard are, in a petrochemical process, able to maintain required petrochemical process conditions by monitoring and adjusting equipment and processes, and describe, respond to, and restore process conditions. Subfield Petrochemical Industry Domain Petrochemical Process and Product Management Status Registered Status date 20 February 2009 Date version published 20 February 2009 Planned review date 31 December 2013 Entry information Open. Replacement information This unit standard replaced unit standard 9593 and unit standard 9594. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) NZ Motor Industry Training Organisation (Incorporated) (MITO) Accreditation and Moderation Action Plan (AMAP) reference 0114 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Performance of the elements of this unit standard must comply with relevant site requirements and the following legislation: Health and Safety in Employment Act 1992; Resource Management Act 1991. New Zealand Qualifications Authority 2016 18725 version 2 Page 2 of 3 2 This unit standard is intended for, but is not limited to, workplace assessment. While all performance criteria must be met it is noted that all range statements within this unit standard are indicative and dependent on enterprise and site specific equipment, procedures, and practices. Any queries can be directed to the NZ Motor Industry Training Organisation (Incorporated) (MITO). 3 For this unit standard the candidate must control a complex process that uses several systems and plant that has some complex equipment. 4 Definitions Distributed control system includes: SCADA, Man Machine Interfaces (MMI). Site requirements mean the site specific documented methods for performing work activities and include health, safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. Elements and performance criteria Element 1 Maintain required petrochemical process conditions by monitoring and adjusting equipment and processes. Performance criteria 1.1 Process data is obtained at scheduled times and recorded in accordance with site requirements. Range sampling, plant logs, product data, distributed control system. 1.2 Operating parameters for each process are identified, monitored, and, where necessary, adjusted to ensure product specifications are met. 1.3 Consequences of deviation from stable operating parameters are explained in terms of effects on product, equipment, and production schedules. 1.4 Any early indications of deviations are recognised and analysed, and equipment and processes are adjusted where necessary. Element 2 Describe, respond to, and restore process conditions in a petrochemical process. Performance criteria 2.1 Circumstances in which emergency shut downs are automatically initiated are described in accordance with site requirements. 2.2 Circumstances in which emergency shut downs are manually initiated are described in accordance with site requirements. New Zealand Qualifications Authority 2016 18725 version 2 Page 3 of 3 2.3 Situations which cannot be remedied within the operator’s authority are reported to the appropriate personnel in accordance with site requirements. 2.4 Corrective actions are taken in the event of a continuing deviation in accordance with site requirements. 2.5 Stable process conditions are restored without delay whilst minimising loss and without compromising safety. 2.6 Any faults are identified and a diagnosis is made which takes all relevant information into account to determine causes. 2.7 Problems and corrective actions taken are communicated to appropriate personnel and recorded in accordance with site requirements. Range incident reporting, logs, fault request, incident investigation, statutory reporting. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016