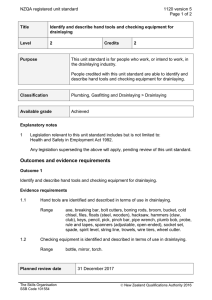

NZQA registered unit standard 18920 version 5 Page 1 of 4

NZQA registered unit standard 18920 version 5

Page 1 of 4

Title

Level

Purpose

Perform glass container forming operations

4 Credits 20

People credited with this unit standard are able to: demonstrate knowledge of glass container forming, forehearth and annealing lehr equipment; and perform advanced operations on an independent section (IS) machine and feeder.

Classification

Available grade

Entry information

Glass and Glazing > Glass Container Manufacturing

Achieved

Recommended skills and knowledge

Unit 23065, Operate glass container forming equipment, or demonstrate equivalent knowledge and skills.

Explanatory notes

Definitions

Enterprise means an organisation where training and/or assessment is taking place, and/or where the trainee is employed.

Enterprise procedures refer to the documented procedures used by the organisation carrying out the work and applicable to the tasks being carried out. They may include but are not limited to

– standard operating procedures, site safety procedures, equipment operating procedures, codes of practice, quality assurance procedures, housekeeping standards, charging of time and materials, management of drawings and documentation, procedures to comply with legislative and local body requirements.

Outcomes and evidence requirements

Outcome 1

Demonstrate knowledge of glass container forming, forehearth, feeder, and annealing lehr equipment.

Competenz

SSB Code 101571

New Zealand Qualifications Authority 2020

NZQA registered unit standard 18920 version 5

Page 2 of 4

Evidence requirements

1.1 The components of the forehearth, and feeder equipment are identified and their operation described.

Range forehearth components – insulated conditioning channel, combustion fans, temperature control system, flow control mechanism, slam shut valve; gob formation equipment components – spout, sleeve, feeder drive mechanism, needles, orifice, shear mechanism; gob loading equipment components – shot-gun funnels,

1.2 interceptor, gob distributor, scoops, troughs, deflectors, cullet shute.

The components of an IS machine are identified and their operation described.

Range components

– machine event timing systems, sweep out mechanism, conveying mechanism, hot end treatment equipment, stacking equipment.

1.3 The components of an annealing lehr are identified and their operation described.

Range components – conveyor, zone controlled oven, cold end surface treatment equipment.

Outcome 2

Perform operations on an IS machine and feeder.

Evidence requirements

2.1 An IS machine is shut down and restarted in accordance with enterprise procedures.

Range evidence is required for two types of IS machine.

2.2 Components of the feeder equipment are changed in accordance with enterprise procedures.

Range components include but are not limited to - sleeves, needles, orifice ring, cams.

Evidence is required for at least four different components.

2.3 Glass conditioning temperatures in the forehearth are monitored to maintain continuity in accordance with enterprise procedures.

Competenz

SSB Code 101571

New Zealand Qualifications Authority 2020

NZQA registered unit standard

2.4

18920 version 5

Page 3 of 4

Product faults are identified and corrected in accordance with enterprise procedures.

Range product fault product fault.

– critical, certain failure, major.

Evidence is required for one fault correction for each type of

2.5 Critical defects are identified and their correction is described in accordance with enterprise procedures.

Range critical defects – birdswing, external stuck glass, false bottom, internal fused glass, internal tear, overpressed finish, spike, stuck plunger, sugary finish internal, ultra thin base, soft internal blister, sharp mould fin, sharp halo, soft blister on finish, finned/pinched neck, flanged finish, knockout finish, birdswing punt, hollow neck, split seam.

Planned review date 31 December 2019

Status information and last date for assessment for superseded versions

Process Version Date Last Date for Assessment

Registration

Revision

1

2

18 December 2001

13 February 2004

31 December 2015

31 December 2015

Revision

Review

3

4

20 September 2004

20 November 2006

31 December 2015

31 December 2017

Review 5 16 April 2015 N/A

Consent and Moderation Requirements (CMR) reference 0134

This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do

.

Please note

Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be granted consent to assess against standards by

NZQA before they can register credits from assessment against unit standards.

Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards.

Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The

CMR also includes useful information about special requirements for organisations wishing

Competenz

SSB Code 101571

New Zealand Qualifications Authority 2020

NZQA registered unit standard 18920 version 5

Page 4 of 4 to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact Competenz qualifications@competenz.org.nz

if you wish to suggest changes to the content of this unit standard.

Competenz

SSB Code 101571

New Zealand Qualifications Authority 2020