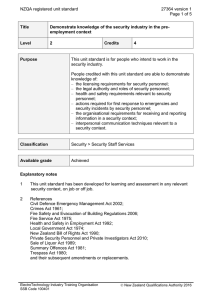

NZQA registered unit standard 22740 version 3 Page 1 of 5

advertisement

NZQA registered unit standard 22740 version 3 Page 1 of 5 Title Demonstrate knowledge of project management in an electrotechnology engineering environment Level 6 Purpose Credits 15 This unit standard covers project management from an electrotechnology engineering perspective. People credited with this unit standard are able to: – demonstrate knowledge of ethical issues and the role of a technician in an engineering context; – demonstrate knowledge of planning and design strategies and issues associated with electrotechnology engineering development and service; – describe component selection and design reliability issues associated with electrotechnology product development; – demonstrate knowledge of national and international standards in relation to electrotechnology engineering; – demonstrate knowledge of the design requirements in the electrotechnology industry; – demonstrate knowledge of quality assurance systems used in electrotechnology manufacture and production; and – describe and demonstrate inter-personal communication skills in a team context. Classification Electrical Engineering > Electrotechnology Available grade Achieved Explanatory notes 1 This unit standard is intended for use in engineering courses at diploma level. 2 References Employment Relations Act 2000; Health and Safety in Employment Act 1992; and all subsequent amendments and replacements. 3 Definitions Ecycling – electronic component recycling. The management of reuse or disposal of old electronic components. Industry practice – practice used and recommended by organisations involved in the electrotechnology industry. PCB – printed circuit board. The Skills Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 22740 version 3 Page 2 of 5 4 All measurements are to be expressed in Système International (SI) units, and, where required, converted from Imperial units into SI units. 5 All activities must comply with: any policies, procedures, and requirements of the organisations involved; the standards of relevant professional bodies; and any relevant legislative and/or regulatory requirements. 6 Range Performance in relation to the outcomes of this unit standard must comply with the Health and Safety in Employment Act 1992. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of ethical issues and the role of a technician in an engineering context. Evidence requirements 1.1 Ethics relating to electrotechnology engineering are explained in accordance with industry practice. 1.2 The role of a technician is described within an engineering hierarchy. 1.3 Issues relating to employment relations, contractual agreements, international accords, and cultural and environmental considerations are described in accordance with industry practice. Outcome 2 Demonstrate knowledge of planning and design strategies and issues associated with electrotechnology engineering development and service. Evidence requirements 2.1 Ideal planning and design procedures are described in accordance with industry practice. 2.2 Strategies to overcome planning and design issues are explained in accordance with industry practice. 2.3 Project management methods and processes are described in accordance with industry practice. Outcome 3 Describe component selection and design reliability issues associated with electrotechnology product development. The Skills Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 22740 version 3 Page 3 of 5 Evidence requirements 3.1 Sources that adversely affect reliability are described in accordance with industry practice. 3.2 The ‘bathtub curve’ is sketched with typical time values, and its different phases are described. Range phases – burn-in, useful life, wear-out. 3.3 The standard reliability curve is sketched, its formula applied, and its significance in relation to component reliability is explained. 3.4 Component reliability is calculated for a given period and constant Hazard Rate or Mean Time to Failure. 3.5 With given reliabilities of the individual systems, the reliabilities of systems in series and in parallel are calculated and reasons for the results are explained. 3.6 Steps to improve component, system, and product reliability are described. 3.7 Steps to ensure fail-to-safe are described in accordance with industry practice. Outcome 4 Demonstrate knowledge of national and international standards in relation to electrotechnology engineering. Evidence requirements 4.1 National and international component standards are identified and their requirements explained and compared in accordance with industry practice. 4.2 Technical compliance issues associated with national and international standards are described in accordance with industry practice. Outcome 5 Demonstrate knowledge of the design requirements in the electrotechnology industry. Evidence requirements 5.1 Design requirements are explained in terms of manufacture, production, safety, servicing, Ecycling, and end of life management. Range 5.2 evidence of three required. Current electrotechnology manufacturing production methods are described in accordance with industry practice. Range The Skills Organisation SSB Code 100401 component selection, reliability, and incorporation; custom part problems; part replacement feasibility, PCB types and layout. New Zealand Qualifications Authority 2016 NZQA registered unit standard 22740 version 3 Page 4 of 5 Outcome 6 Demonstrate knowledge of quality assurance systems used in electrotechnology manufacture and production. Evidence requirements 6.1 Quality assurance systems used in electrotechnology manufacture and production industries are described through case studies terms of need, implementation, safety, and effectiveness. Outcome 7 Describe and demonstrate interpersonal communication skills in a team context. Evidence requirements 7.1 Team communications methods and pathways are described and applied. includes but is not limited to – one on one, group discussion, informal brief, record keeping. Range 7.2 Methods to avoid and overcome conflicts in a team are explained and applied in terms of situation, effectiveness, and practicality. Planned review date 31 December 2014 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 18 December 2006 N/A Rollover and Revision 2 15 March 2012 N/A Revision 3 15 January 2014 N/A Consent and Moderation Requirements (CMR) reference 0003 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and The Skills Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 22740 version 3 Page 5 of 5 which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact The Skills Organisation reviewcomments@skills.org.nz if you wish to suggest changes to the content of this unit standard. The Skills Organisation SSB Code 100401 New Zealand Qualifications Authority 2016