Demonstrate knowledge of and test materials for mechanical engineering applications

advertisement

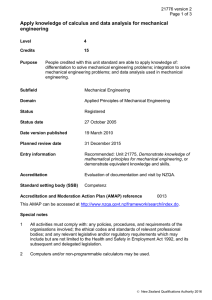

21785 version 2 Page 1 of 3 Demonstrate knowledge of and test materials for mechanical engineering applications Level 5 Credits 15 Purpose People credited with this unit standard are able to: describe the properties of materials used in mechanical engineering applications; and test material properties and identify likely causes of material failure. Subfield Mechanical Engineering Domain Applied Principles of Mechanical Engineering Status Registered Status date 27 October 2005 Date version published 19 March 2010 Planned review date 31 December 2015 Entry information Open. Replacement information This unit standard replaced unit standard 11394. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0013 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 All activities must comply with: any policies, procedures, and requirements of the organisations involved; the ethical codes and standards of relevant professional bodies; and any relevant legislative and/or regulatory requirements, which may include but are not limited to the Health and Safety in Employment Act 1992, Resource Management Act 1991, Hazardous Substances and New Organisms Act 1996, and their subsequent and delegated legislation. New Zealand Qualifications Authority 2016 21785 version 2 Page 2 of 3 2 Range Competence is to be demonstrated with reference to a ferrous metal and three other materials which may include but are not limited to: aluminium, brass, copper, zinc, magnesium, titanium, polymers, solid timber, concrete, ceramics, adhesives, composites; individually and/or in combination. 3 Definition Worksite procedures refer to documents that include: worksite rules, codes, and practices; equipment operating instructions; documented quality management systems; and health and safety requirements. Elements and performance criteria Element 1 Describe the properties of materials used in mechanical engineering applications. Performance criteria 1.1 Description of material properties are related to manufacturing processes and establish the suitability of materials. Range properties may include but are not limited to – hardness, rigidity, strength (including impact strength), ductility, malleability, machinability, treatability, creep, fatigue, toughness, resistance to corrosion and erosion, compatibility, permeability, resistivity, electrical and thermal conductivity, toxicity, transition temperature, co-efficient of expansion; processes may include but are not limited to – welding, forging, casting, cutting, pressing, bending, spinning, machining, extrusion, finishing. 1.2 Interpretation of equilibrium diagrams establishes the suitability of materials for their intended application. 1.3 Changes in material properties are explained in terms of causes and effects. Range causes may include but are not limited to – time, treatment, alloying and composition, work, contamination, environment, stress, surface finish, corrosion. Element 2 Test material properties and identify likely causes of material failure. Performance criteria 2.1 Destructive and/or non-destructive testing methods are matched to the properties to be tested. New Zealand Qualifications Authority 2016 21785 version 2 Page 3 of 3 2.2 Destructive and/or non-destructive tests are conducted in accordance with manufacturing specifications and worksite procedures. 2.3 Analysis of data confirms the material properties and establishes the nature of any actual or potential materials-associated problems. Range data may include but is not limited to – observation, measurements, laboratory reports. 2.4 Likely causes of material failure are identified in terms of material properties, material structure, and/or environment. 2.5 The assistance of qualified professionals is sought for specialist advice on causes of material failure. 2.6 Required documentation is completed in accordance with worksite procedures. Range may include hard copy and/or electronic documentation. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016