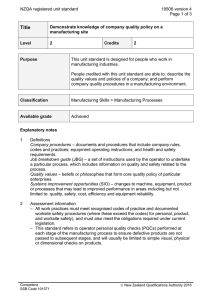

Join components for the production of marine inflatables

advertisement

11775 version 4 Page 1 of 3 Join components for the production of marine inflatables Level 4 Credits 60 Purpose People credited with this unit standard are able to: prepare for joining marine inflatable components; pre-glue and glue components and sub-assemblies; and weld components and sub-assemblies. This unit standard is applicable to non-regulated marine inflatables, such as non-certified boats, marker buoys, oil booms, and fenders. Subfield Boating Industries Domain Marine Sales and Services Status Registered Status date 27 August 1997 Date version published 20 March 2009 Planned review date 31 December 2012 Entry information Prerequisite: Unit 11774, Buff and clean marine inflatable components for joining, or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Boating Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0136 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Company procedures – the documented procedures for the machine and/or worksite. 2 Evidence of the elements of this unit standard must be presented across the following contexts: welding methods – hand-held hot air welding, machine hot air welding, high frequency machine welding; evidence is required for two. New Zealand Qualifications Authority 2016 11775 version 4 Page 2 of 3 3 The following apply to the performance of all elements of this unit standard: a All required equipment must be set up, started up, operated, and shut down in accordance with company procedures. b All work practices must meet recognised codes of practice and documented worksite health and safety procedures (where these exceed code) for personal, product, and worksite health and safety, and must meet the obligations required under the Health and Safety in Employment Act 1992 and subsequent and delegated legislation. c All work practices must meet recognised codes of practice and documented worksite environmental procedures (where these exceed code) for personal, product, and worksite environmental matters, and must meet the obligations required under the Resource Management Act 1991 and subsequent and delegated legislation. d All work practices must meet documented worksite quality management requirements. These include documentation of activities, events, and decisions. 4 This unit standard can be assessed on job. Elements and performance criteria Element 1 Prepare for joining marine inflatable components. Performance criteria 1.1 Checking of the type, number, and standard of supplied components and subassemblies ensures that the required final assembly can be produced. Range standards of cleanliness, buffing, construction lines. 1.2 Selection of formers and jointers matches job requirements. 1.3 Joining marks are visible, and are matched to shape requirements. Element 2 Pre-glue and glue components and sub-assemblies. Performance criteria 2.1 Adhesive selection is matched to fabric type. Range hyperlon, polyvinyl chloride. 2.2 Adhesives are mixed, applied, and cured in accordance with manufacturer’s specifications and recommendations. 2.3 Components and sub-assemblies are pre-glued in accordance with job requirements. New Zealand Qualifications Authority 2016 11775 version 4 Page 3 of 3 2.4 Sequence of pre-gluing and gluing meets the requirements of the company work programme. 2.5 Glued joints are completed and tested to company specifications for location and strength. Element 3 Weld components and sub-assemblies. Performance criteria 3.1 Test samples are produced and tested in accordance with company requirements. 3.2 Sequence of welding meets the requirements of the company work programme. 3.3 Welded joints are completed and tested to company specifications for location and strength. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Boating Industry Training Organisation training@bia.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016