SNOWSPORT EQUIPMENT Fit and remount bindings to skis

advertisement

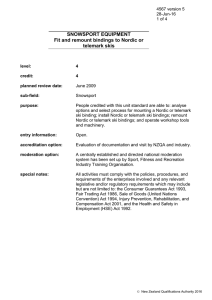

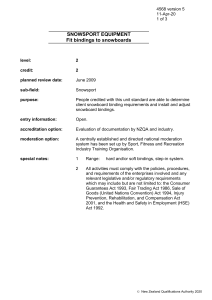

4566 version 5 28-Jun-16 1 of 4 SNOWSPORT EQUIPMENT Fit and remount bindings to skis level: 4 credit: 8 planned review date: June 2009 sub-field: Snowsport purpose: People credited with this unit standard are able to: analyse options and select process for mounting a binding; install and adjust ski bindings; remount ski bindings; and operate workshop tools and machinery. entry information: Open. accreditation option: Evaluation of documentation and visit by NZQA and industry. moderation option: A centrally established and directed national moderation system has been set up by Sport, Fitness and Recreation Industry Training Organisation. special notes: 1 DIN (Deutsch Industrial Norm) is defined as an international standard for binding manufacture. 2 All activities must comply with the policies, procedures, and requirements of the enterprises involved and any relevant legislative and/or regulatory requirements which may include but are not limited to: the Consumer Guarantees Act 1993, Fair Trading Act 1986, Sale of Goods (United Nations Convention) Act 1994, Injury Prevention, Rehabilitation, and Compensation Act 2001, and the Health and Safety in Employment (HSE) Act 1992. New Zealand Qualifications Authority 2016 4566 version 5 28-Jun-16 2 of 4 SNOWSPORT EQUIPMENT Fit and remount bindings to skis Elements and Performance Criteria element 1 Analyse options and select process for mounting a binding. performance criteria 1.1 The boot, binding, and ski are analysed for compatibility according to DIN standards and manufacturer’s recommendations. 1.2 The compatibility of interfaces and/or lifters are identified. 1.3 The DIN setting selected matches the client’s details. Range: 1.4 height, weight, age, boot sole length, skier ability. The ski equipment is checked for manufacturer's specifications and warranty conditions in regard to mounting instructions and requirements. Range: construction, materials, thickness and width of ski, screw retention plates, binding placement marks, boot mid-sole marks. 1.5 Correct jig or template is selected for mounting the binding, interface or lifter, jig is adjusted to boot length and positioned on the ski, with boot centre mark or boot toe aligned to correct position on the ski. 1.6 Selected binding drill meets requirements of ski type and construction, manufacturer's recommendations, and company practice. Range: ski type – adult ski, junior ski; construction – metal, composite materials, wood, fibreglass. element 2 Install and adjust ski bindings. performance criteria 2.1 The binding is mounted according to the ski manufacturer's recommendations. Range: drilled and/or tapped. New Zealand Qualifications Authority 2016 4566 version 5 28-Jun-16 3 of 4 SNOWSPORT EQUIPMENT Fit and remount bindings to skis 2.2 Adhesive is applied and binding screws are seated without damaging the ski or screw according to manufacturer's recommendation and company practice. 2.3 The integrated brake is engaged and functions smoothly. 2.4 Cover plates and anti-friction devices are positioned to meet the binding, ski, and boot requirements. 2.5 Bindings are adjusted to correct forward pressure setting and the skier's ability, weight, age, and boot sole length, using the manufacturer's recommendations. Range: 2.6 forward pressure and heel adjustment, toe unit adjustment, release settings, centering. Binding release mechanisms are function tested. element 3 Remount ski bindings. performance criteria 3.1 The binding is remounted according to company requirements and manufacturers’ specifications. Range: 3.2 may include – plugging holes, drilling new holes, inserting helicoil, glues, tap top sheet. Knowledge is demonstrated of helicoils, and when they are required. element 4 Operate workshop tools and machinery. performance criteria 4.1 Workshop machinery is operated according to manufacturers' specifications and to operating instructions. 4.2 Workshop tools and machinery are cleaned and maintained according to manufacturers' recommendations. New Zealand Qualifications Authority 2016 4566 version 5 28-Jun-16 4 of 4 SNOWSPORT EQUIPMENT Fit and remount bindings to skis 4.3 Safety equipment is used while working with workshop machinery and according to Health and Safety in Employment Act 1992 requirements. 4.4 Gases, flammable liquids, and chemicals are stored and used according to safe workplace practices as required under the Health and Safety in Employment Act 1992. 4.5 Repair and/or maintenance records are kept according to company procedures. Comments on this unit standard Please contact the Sport, Fitness and Recreation Industry Training Organisation info@sfrito.org.nz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0050 which can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016