Presentation - PowerPoint format

advertisement

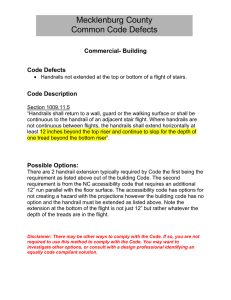

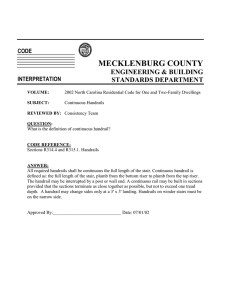

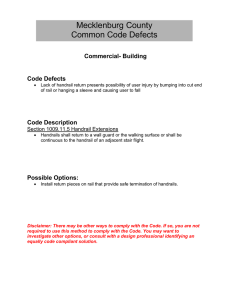

The Boll Family YMCA Alvaro Zumaran Construction Management April 10, 2006 Project Background • • • • • • Building Name: The Boll Family YMCA Location: 1401 Broadway - Detroit, MI 48226 Size: 110,000 SF Cost: $29 Million Occupancy: Recreational; IIA Construction Dates: December ’03 - December ‘05 Project Background • Primary Project Team - Owner: YMCA of Metropolitan Detroit - Architects/Engineers: SmithGroup - Construction Manager: Barton Malow Co. Project Background • Project Highlights - First new YMCA to be built in Detroit in 90 years - Performing arts theatre, sports arena, childcare facility - Distinctive “stepped” shape - Staggered floor levels - High visibility Interactive Website Virtual Tour Website Agenda Analysis 1 – Foundation Analysis 2 – Handrails Analysis 3 – Mechanical Room Research Topic – Integrated Design Management Analysis 1 - Foundation •Goals •Background • Analyze the cost of materials – concrete and formwork, of 2 separate foundation types • Compare RS Means and ICE 2000 •Proposed data to BMC budget data and schedule •Cost • Recommend best option Comparison Analysis 1 - Foundation •Goals •Backgroun d •Proposed •Cost Comparison • Strip footings ~25,500 SF footprint ~765 Ft perimeter ~120 days • Combined drilled and formed piers Approximately 70 drilled piers and 36 formed piers Analysis 1 - Foundation •Goals •Background •Proposed •Cost Comparison • Mat slab foundation - > 3’ thick - Approximately 60 days - volumetric shrinkage = possible cracking - Conflicting RS Means and ICE 2000 pricing Analysis 1 - Foundation •Goals •Background •Proposed •Cost Compariso n Analysis 1 - Foundation •Goals •Background •Proposed •Cost Compariso n Analysis 1 - Foundation •Goals •Price difference between ICE 2000 •Background •Proposed •Cost Compariso n estimate and RS Means estimate: ~$165,000 Analysis 1 - Foundation •Goals •Background •Proposed •Cost Compariso n Analysis 1 - Foundation •Goals •Background •Proposed •Cost Compariso n Analysis 1 - Foundation •Goals • Price according to BMC data: •Background •Proposed •Cost Compariso n ~$846,000 • Compared to ICE 2000: ~$199K • Compared to RS Means: ~$34K Analysis 1 - Foundation •Goals •Background •Proposed •Cost Comparison • Cost for mat system is not practical compared to strip footings • Material durability - potential for visible cracking in exposed floors and mechanical equipment vibrations • Insufficient soil stability - as stated in the geo-tech reports Analysis 2 - Handrails Goals Research cost for an alternate handrail system Calculate and compare cost of maintenance for each system Suggest most cost-effective system Analysis 2 - Handrails Goals Woven wire mesh in-fill panels Current system 1,130 linear feet - running track - ‘main’ areas Aesthetic feel Analysis 2 - Handrails Current system Proposed solution Aluminum handrails - affordable - anodized ◦ durability ◦ aesthetic feel ◦ corrosion, stain, scratch resistance Analysis 2 - Handrails Proposed solution Cost comparison Analysis 2 - Handrails Cost comparison Analysis 2 - Handrails Cost comparison Analysis 2 - Handrails Cost comparison Conclusion Aluminum handrail system is most economically feasible Owner and architect decide - aesthetics - conformity Analysis 3 – Mechanical Room • Goals • Explore current system - complications - possible long term effects • Suggest a less expensive alternative that is just as effective Analysis 3 – Mechanical Room • Goals • Current system • Issue with vertical rise • Splashing at air gap connecting pool line to sanitary line • Expensive solution – bring in tank – indirectly tie 6” pool line to 8” sanitary line • Possible long term effects – decomposition of sanitary line (?) – corrosion of steel decking (?) Analysis 3 – Mechanical Room • Goals • Current system • Alternate solution • Add another line going to sump pump (proper vertical rise) • Install new sump pump – handle 430 GPM – break open floor – connect sump to pool trap line – already tied into sanitary line Mechanical Room Schematic *8” pool sump * ** discharge Mechanical Room Schematic Analysis 3 – Mechanical Room • Goals • Current system • Alternate solution • Cost comparison • Current system information provided by PM and Mechanical contractor – 12’ polypropylene tank w/ 64” diameter – 1.5 HP pump, infrared beams, and electric switches – labor and installation Total Price: ~$35,000 Analysis 3 – Mechanical Room • Goals • Current system • Alternate solution • Cost comparison Analysis 3 – Mechanical Room • Goals • Current system • Alternate solution • Cost comparison Analysis 3 – Mechanical Room • Goals • Current system • Alternate solution • Cost comparison • Less expensive to install new sump and trap line (~$7,500) • Proposed system takes up less space • Proposed system does not pose threats to structural decking Research Analysis Integrated design management background Synergy amongst the entities Effective planning: possible reduction in budget and schedule Using the Design-Build delivery method Research Analysis Problems Added costs to budget/days to schedule - trade conflicts - misinterpretation of drawings - lead times - any other unforeseen conditions Research Analysis Research Online Reports Interviews with the ‘Heads’ of a project - Owner: Mrs. Lorie Uranga (YMCA) - Engineer: Mr. Benjamin Gerald (Holder Construction Co.) - Architect: Mrs. Jana Hayford (SmithGroup) Research Analysis Research Points made by reports - DB saves time, money and reduces conflict - Most helpful when project is driven by cost & schedule - Best suited for projects that are well defined - Management of ‘interfaces’ - Good managerial skills and experience Research Analysis Research Data Research Analysis Research Main Points From Interviews - Owner’s perspective - ‘cost effective’ systems need more maintenance - design aspects are sacrificed for time and schedule - some projects are better suited for it compared to others - sometimes hard to balance powers Research Analysis Research Main Points From Interviews - Engineer’s perspective - performance specifications put most risk on contractor - value engineering: before the design is complete - design-Build creates synergy between aesthetic thinkers and logical thinkers - owner’s desired level of involvement determine the execution of a D-B or a DBB delivery method - D-B: overlap of phases. DBB: linear approach Research Analysis Research Main Points From Interviews - Architect’s perspective - early budget and up-front cost - communication should be carefully handled - IDM is dependent on client and complexity of building - performance specifications and longevity of product - ‘cost cutting’ mode and no competition for contractor Research Analysis Conclusion ◦ Chemistry and communication are top-priority ◦ Client must be specific and time & money are the most important factors ◦ Performance specifications handled carefully and are usually a one-sided risk ◦ Complexity of project ◦ PM with strong personality and high expertise and skill ◦ Examples from YMCA project Acknowledgements • • • • Barton Malow Co. SmithGroup YMCA of Metro Detroit Architectural Engineering Faculty • My family and friends Questions? Analysis 1-Foundation Schedule Comparison 3,300 CY / 56.4 (daily output) = ~60 days