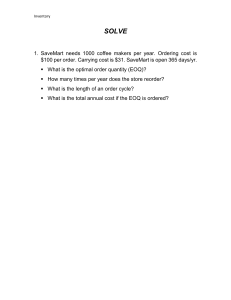

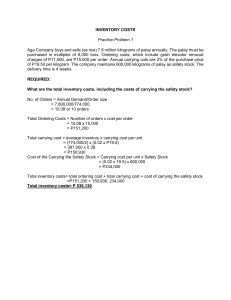

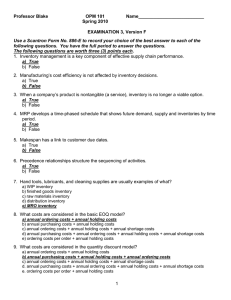

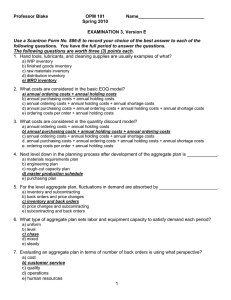

Inventory Management Assignment: EOQ, ABC Analysis, Costs

advertisement

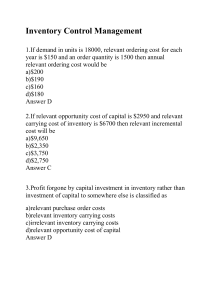

MANAGEMENT OF MANUFACTURING SYSTEM ASSIGNMENT 3 1. A manufacturer requires rivets at an approximately constant rate of 2500 kgs per year. The cost of rivets is RS 40 per kg. The company's purchase manager estimates that the carrying cost of inventory 10% per year. Procurement cost is RS. 200 per order:a. (i). How frequently should orders for rivets be placed and what quantities should be ordered? Also calculate total cost of inventory. b. (ii). If the ordering cost is RS 40 per order and 15% is the carrying cost, how would the optimal policy change? How much is the loss per years because of imperfect cost information? 2. A hardware store produces and sells hardware items. Following information is available: Expected annual sales = 8000 units Ordering cost = RS 180 per order Holding cost = 10% of average inventory value. The items can be purchased in the following schedule: You are required to determine the order size. 3. Explain the various costs associated with inventory? 4. Explain inventory control by ABC analysis? 5. What is back order? 6. Why we say that EOQ model is not very sensitive?