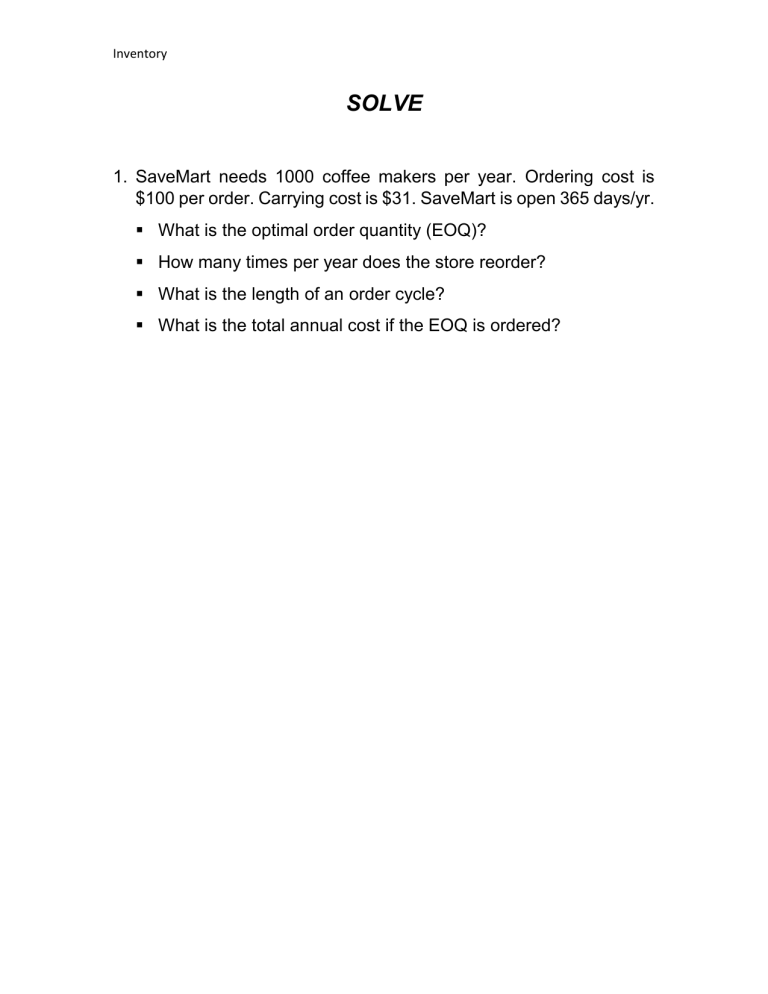

Inventory SOLVE 1. SaveMart needs 1000 coffee makers per year. Ordering cost is $100 per order. Carrying cost is $31. SaveMart is open 365 days/yr. What is the optimal order quantity (EOQ)? How many times per year does the store reorder? What is the length of an order cycle? What is the total annual cost if the EOQ is ordered? Inventory 2. The Friendly Sausage Factory (FSF) can produce hot dogs at a rate of 5,000 per day. FSF supplies hot dogs to local restaurants at a steady rate of 250 per day. The cost to prepare the equipment for producing hot dogs is $66. Annual holding costs are 45 cents per hot dog. The factory operates 300 days a year. Find: a) The optimal run size. b) Minimum total annual cost for carrying and setup. c) The cycle length. d) The run length . Inventory 3. A manager has just received a revised price schedule from a vendor. What order quantity and number of orders should the manager use in order to minimize total costs? Annual Demand is 120 units, ordering cost is $8, and annual carrying cost is $1 per unit. The price schedule is: Quantity Price 1 to 39 $14 40 to 59 $13 60 to 89 $12 90 and more $11 Inventory 4. Suppose that you are the manager of a production department that uses 400 boxes of rivets per year. The supplier quotes you a price of $8.50 per box for an order size of 199 boxes or less, a price of $8.00 per box for orders of 200 to 999 boxes, and a price of $7.50 per box for an order of 1,000 or more boxes. You assign a holding cost of 20 percent of the price to this inventory. Assume ordering cost is $80/order. What order quantity would you use to minimize the total annual costs and what is the number of orders per year?