version E

advertisement

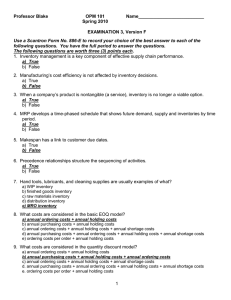

Professor Blake OPM 101 Spring 2010 Name__________________________ EXAMINATION 3, Version E Use a Scantron Form No. 886-E to record your choice of the best answer to each of the following questions. You have the full period to answer the questions. The following questions are worth three (3) points each. 1. Hand tools, lubricants, and cleaning supplies are usually examples of what? a) WIP inventory b) finished goods inventory c) raw materials inventory d) distribution inventory e) MRO inventory 2. What costs are considered in the basic EOQ model? a) annual ordering costs + annual holding costs b) annual purchasing costs + annual holding costs c) annual ordering costs + annual holding costs + annual shortage costs d) annual purchasing costs + annual ordering costs + annual holding costs + annual shortage costs e) ordering costs per order + annual holding costs 3. What costs are considered in the quantity discount model? a) annual ordering costs + annual holding costs b) annual purchasing costs + annual holding costs + annual ordering costs c) annual ordering costs + annual holding costs + annual shortage costs d. annual purchasing costs + annual ordering costs + annual holding costs + annual shortage costs e. ordering costs per order + annual holding costs 4. Next level down in the planning process after development of the aggregate plan is ____________. a) materials requirements plan b) engineering plan c) rough-cut capacity plan d) master production schedule e) purchasing plan 5. For the level aggregate plan, fluctuations in demand are absorbed by _______________________. a) inventory and subcontracting b) back orders and price changes c) inventory and back orders d) price changes and subcontracting e) subcontracting and back orders 6. What type of aggregate plan sets labor and equipment capacity to satisfy demand each period? a) uniform b) level c) chase d) mixed e) steady 7. Evaluating an aggregate plan in terms of number of back orders is using what perspective? a) cost b) customer service c) quality d) operations e) human resources 1 Professor Blake OPM 101 Spring 2010 Name__________________________ 8. What is an information system designed to integrate internal and external members of the supply chain? a) material requirements planning b) master production schedule c) capacity requirements planning d) aggregate planning e) enterprise resource planning 9. Companies use to check that enough work is scheduled for operations and that the amount of work scheduled is feasible. a) capacity management b) closed-loop requirements planning c) cut requirements planning d) capacity resources planning e) capacity requirements planning 10. CRP systems are used to check that the amount of work: a) meets the MRP directive. b) meets the ERP directive. c) will make a profit. d) is feasible. e) meets OSHA requirements. 11. In MRP, the starting points for each part and material needed to accomplish the master production schedule are the ________________________. a) net requirements b) gross requirements c) planned releases d) scheduled receipts e) planned receipts 12. Which of the following techniques loads jobs without regard to the capacity available to do the work? a) finite loading b) infinite loading c) forward scheduling d) backward scheduling e) input/output control 13. Which of the following scheduling techniques determines the earliest possible completion time for a job? a) finite loading b) infinite loading c) forward scheduling d) backward scheduling e) input/output control 2 Professor Blake OPM 101 Spring 2010 Name__________________________ 14. What does job flow time measure? a) the time a job spends in the shop b) due-date performance c) the amount of time it takes to finish a batch of jobs d) job tardiness e) job lateness 15. What does average number of jobs in the system measure? a) WIP inventory b) due-date performance c) makespan d) job tardiness e) job lateness 16. The critical path is the sequential path of interrelated activities which has the ________________. a) most activities b) longest time c) most nodes d) most events e) most arrows 17. When we are unsure about the duration of project activities, we use a) variable b) probabilistic c) estimated d) deterministic e) cumulative time estimates. 18. Shortening the total time for completing a project by incurring higher costs from shortening activities is ___________________. a) normal cost b) backward pass c) crashing d) leveling e) project control 19. Inventory management is a key component of effective supply chain performance. a) True b) False 20. Manufacturing’s cost efficiency is not affected by inventory decisions. a) True b) False 21. When a company’s product is nontangible (a service), inventory is no longer a viable option. a) True b) False 22. MRP develops a time-phased schedule that shows future demand, supply and inventories by time period. a) True b) False 3 Professor Blake OPM 101 Spring 2010 Name__________________________ 23. Makespan has a link to customer due dates. a) True b) False 24. Precedence relationships structure the sequencing of activities. a) True b) False The following problems are worth ten (10) points each. 1. Suppose that your company sells a product for which the annual demand is 10,000 units. Holding costs are $1.00 per unit per year, and setup costs are $200 per order 2. (a) What is the economic order quantity for your product? Q= = = = 2,000 units (b) What is the total annual cost of ordering and holding? TC = D/Q*S + Q/2*H = 10,000/2000*200 + 2000/2*1 = 1,000 + 1,000 = $2,000 2. Given the following data: Item J K L M N O P Q Usage per Parent 3 1 2 4 2 1 6 Lead Time (weeks) 3 2 1 2 3 2 1 2 Gross Requirements 10 30 10 20 120 60 60 360 The end product J is made from components K, L, and M. K is made from N and O. O is made from P and Q. (a) What is the replenishment lead time for J, assuming there are no inventories? JL=3+1=4 JM=3+2=5 JKN=3+2+3=8 JKOP=3+2+2+1=8 JKOQ=3+2+2+2=9 Replenishment time is 9 weeks (b) Calculate the gross requirements for each of the components if the company plans to build 10 of its J model. Assume that there are no beginning inventories. See above 4 Professor Blake OPM 101 Spring 2010 Name__________________________ 3. Jackie is the owner and the manager of an auto repair company. In order to be fair to all the customers, Jackie decides to use the FCFS priority rule in job sequencing. Currently, four cars need to be repaired. Assume that the cars arrive in the order listed, that is, A first, then B, then C, then D. The estimated labor times (in days) and promise dates are shown in the following table. Customers usually do not pick up their cars early. Today is day 0. Car Estimated Labor Time Promise Date A 5 5 B 10 18 C 1 12 D 3 15 Based on the FCFS sequence, calculate the following performance measures: (a) makespan, (b) average job flow time, (c) average number of jobs in the system, (d) average job tardiness. Jobs A B C D a. b. c. d. Labor Time 5 10 1 3 19 Flow Time 5 15 16 19 55 Due Date 5 18 12 15 Tardiness 0 0 4 4 8 Makespan = 19 days Avg. Job Flow Time = 55/4 = 13.75 days Avg. Number of Jobs = 55/19 = 2.89 jobs Avg. Job Tardiness = 8/4 = 2 days 5 Professor Blake OPM 101 Spring 2010 Name__________________________ 6