Ian Gluck Mentor: Dr. Christine Kelly

advertisement

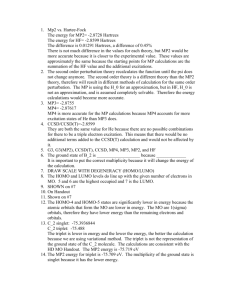

Ian Gluck Mentor: Dr. Christine Kelly OSU Dept. of Chemical, Biological and Environmental Engineering The United States is currently the world’s largest producer of ethanol Majority of American ethanol is corn-based Inefficient Conflicts with food demands Cellulosic (wood-based) ethanol has several advantages Lower greenhouse gas emissions Biomass is cheap to produce Cellulose must be converted to glucose Performed by cellulases Process is hindered by lignin A large, irregular polymer Surrounds the cellulose Lignin Cellulose Manganese peroxidase (MnP) Found in white-rot fungi Degrades lignin White-rot fungi cannot be effectively mass produced DNA responsible for MnP production was cloned into a yeast (Pichia pastoris) Yeast is cultivated to create recombinant manganese peroxidase (rMnP) Performs same lignin-degrading function Crude yeast broth has many other proteins, as well as rMnP For rMnP biocatalysis pathways to be investigated, it must be: Concentrated Purified To test the effectiveness of a variety of methods in the concentration and purification of recombinant manganese peroxidase White-rot fungi cultivation broth Filtered Cell-free broth submitted to: A concentration process A purification process Acetone precipitation Centrifugation/Resolubilization Overnight freezing Lyophilization (freeze-drying) Dialysis Ion exchange chromatography Uses ionic interactions to separate molecules of different charge Diethylaminoethyl (DEAE) column -O-CH2-CH2-N+H(CH2CH3)2•Cl- Positive charge with negative Cl- ions Cl- ions are exchanged for MnP, and vice versa - Cl - Cl - - - - - - - Cl - - - Cl - - - - - - Cl - - Cl - - MnP - - Cl - - - Cl - - - - -- Cl - - - Cl - + - Cl - + + - Cl - + DEAE + - Cl - - + + - Cl - - MnP - + + + - Cl - - - - - Fungi Culture - Protein - Enzyme Activity Assay Sample of subject solution is mixed with buffers, DMP and H2O2 MnP in solution reacts with peroxide and DMP, forming an orange color Absorbance of orange solution is measured Absorbance is used to calculate MnP concentration Concentration * Volume Mass Mass of MnP/ *100 = Percent Yield Previous mass of MnP Total Protein Assay Mass of MnP is divided by protein mass Absorbance is measured and used to find protein concentration Concentration * Volume = Mass Similar process to MnP assay Mass Fraction Step Sample Volume (L) MnP Conc. (mg/L) MnP Mass (mg) Yield (%) Protein Conc. (mg/L) Protein Mass (mg) Yield (%) Mass Fraction (*10-5) Crude Broth 0.1 0.139 1.39*10-2 - 1503 150.3 - 9.30 Precipitation/ Centrifugation 0.03 0.350 1.23*10-2 88.5 2855 85.65 56.9 21.6 Lyophilization 0.004 3.00 1.19*10-2 96.7 1017 4.068 4.7 251 Dialysis 0.008 1.09 8.68*10-3 72.9 - - - - Ion Exchange 0.015 0.433 6.50*10-3 74.9 593 8.888 - 73.1 Desired Outcomes MnP yield > 50% Dramatic increase in mass fraction Possible outcomes of success Improve research on MnP transformations of lignin Cellulosic ethanol is able to be produced more efficiently on an industrial scale Product of lignin degradation is examined for possible applications A model system for purifying proteins is developed HHMI Dr. Kevin Ahern Dr. Christine Kelly Kelsey Yee OSU Department of Chemical, Biological and Environmental Engineering