English For Arch & Civil II

Prepared by : Indra Tj

UNIT 10 . NOVEMBER 2003

73

CIVIL ENGINEERING MAGAZINE

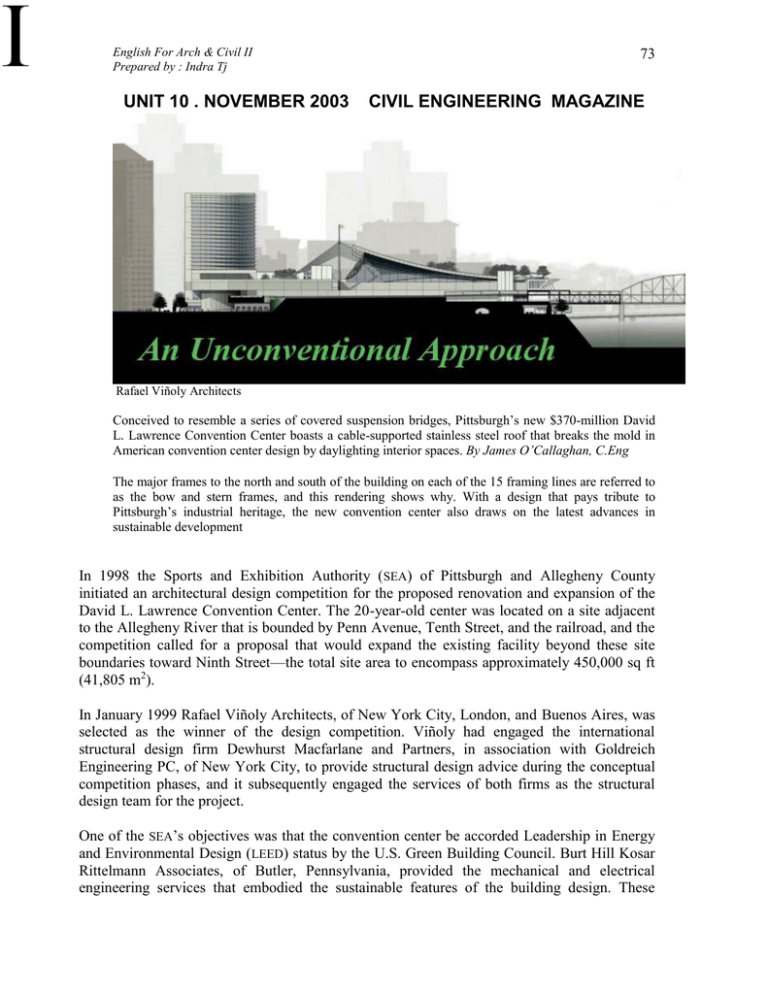

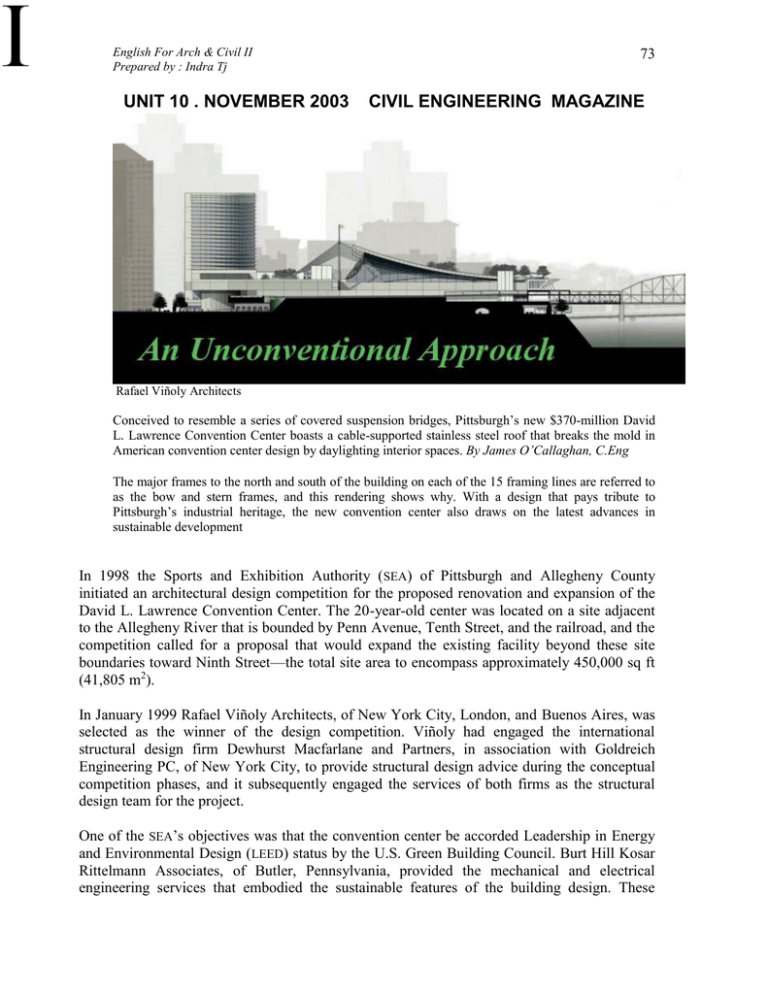

Rafael Viñoly Architects

Conceived to resemble a series of covered suspension bridges, Pittsburgh’s new $370-million David

L. Lawrence Convention Center boasts a cable-supported stainless steel roof that breaks the mold in

American convention center design by daylighting interior spaces. By James O’Callaghan, C.Eng

The major frames to the north and south of the building on each of the 15 framing lines are referred to

as the bow and stern frames, and this rendering shows why. With a design that pays tribute to

Pittsburgh’s industrial heritage, the new convention center also draws on the latest advances in

sustainable development

In 1998 the Sports and Exhibition Authority (SEA) of Pittsburgh and Allegheny County

initiated an architectural design competition for the proposed renovation and expansion of the

David L. Lawrence Convention Center. The 20-year-old center was located on a site adjacent

to the Allegheny River that is bounded by Penn Avenue, Tenth Street, and the railroad, and the

competition called for a proposal that would expand the existing facility beyond these site

boundaries toward Ninth Street—the total site area to encompass approximately 450,000 sq ft

(41,805 m2).

In January 1999 Rafael Viñoly Architects, of New York City, London, and Buenos Aires, was

selected as the winner of the design competition. Viñoly had engaged the international

structural design firm Dewhurst Macfarlane and Partners, in association with Goldreich

Engineering PC, of New York City, to provide structural design advice during the conceptual

competition phases, and it subsequently engaged the services of both firms as the structural

design team for the project.

One of the SEA’s objectives was that the convention center be accorded Leadership in Energy

and Environmental Design (LEED) status by the U.S. Green Building Council. Burt Hill Kosar

Rittelmann Associates, of Butler, Pennsylvania, provided the mechanical and electrical

engineering services that embodied the sustainable features of the building design. These

English For Arch & Civil II

Prepared by : Indra Tj

74

include natural ventilation and daylighting for the main exhibit halls as well as the use of

recycled water to flush toilets. An application for LEED certification has been submitted, and on

the basis of very thorough preliminary assessments the project is expected to qualify for an

LEED gold rating, one of the highest. This would distinguish the convention center as the

largest LEED-approved building in the world and the only convention center in the United

States to possess LEED certification. Computer modeling has indicated that the convention

center will be approximately 35 percent more energy efficient than a similar center designed in

strict accordance with current codes and standards.

Viñoly’s vision was to relate the building to Pittsburgh’s urban topography and industrial history.

The site’s proximity to the Seventh Street and Ninth Street suspension bridges inspired Viñoly

to design a structure reflective of early-20th-century engineering technology. The Sixth Street,

Seventh Street, and Ninth Street bridges—the Three Sisters—link the north side of the city to

the Golden Triangle area and stand as the only example in the world of three identical bridges

positioned side by side.

Ultimately, the convention center will incorporate 1.5 million sq ft (139,350 m2) of space,

including 330,000 sq ft (30,657 m2) of exhibit space—250,000 sq ft (23,225 m2) of it

devoid of columns. The center includes a main hall, a secondary hall, meeting rooms, two

lecture halls, a 33,000 sq ft (3,066 m2) ballroom, and a 700-space garage.

Viñoly’s vision was to relate the building to Pittsburgh’s urban topography and industrial

history. The site’s proximity to the Seventh Street and Ninth Street suspension bridges

inspired Viñoly to design a structure reflective of early-20th-century engineering

technology. The Sixth Street, Seventh Street, and Ninth Street bridges, referred to

collectively as the Three Sisters, link the north side of the city to the Golden Triangle area

and stand as the only example in the world of three identical bridges positioned side by

English For Arch & Civil II

Prepared by : Indra Tj

75

side. The design was also driven, however, by the physical features and limitations of the

site, which led to the evolution of a building that, in plan, tapers from east to west.

The engineers collaborated closely with Viñoly in determining methods of effecting a

clear span roof above the main exhibition space in a manner sympathetic to the ideals of

the city’s original suspension bridge technology. The result is a roof structure of primary

suspension cables over central masts anchored at the end by the main building structure.

But the design and construction of this roof structure presented very significant structural

challenges.

Uplift in the upper cables is prevented by the action of the lower damping cables. The arch of the

lower cable reflects that of the upper cable. The lower damping cables extend over the main

exhibition floor of the convention center and help to support the ventilation system.

One of the primary design dictates was that the David L. Lawrence Convention Center be

a convention facility encompassing the largest column-free space in the United States.

This led to an investigation of long-span structures; subsequently the idea of integrating

the principles of suspension bridge design into the building resulted in what was seen as

an ideal method for creating a clear span.

The structural design of the building was developed to minimize the need for the concrete

anchorages typically used in suspension bridges to contain the massive tension forces

developed in the supporting cables. The building’s design evolved in a way that would

efficiently accommodate not only the overall structural demands but also the major

internal loads developed by the tension cable roof structure. The anchorages at either end

of the cable are major steel frames that transfer the roof tension loads and form the

building’s floor and roof support. A key principle of the structural design is the resolution

of these high tension forces within the building’s framework, reducing the need to resolve

English For Arch & Civil II

Prepared by : Indra Tj

76

the forces through costly foundation works. This resolution was achieved by using steel

trusses, floor-supporting beams, and a tension grade beam.

The lateral stability of the building is achieved by using the main concrete cores located

on either side of the main exhibition floor. Lateral loads imposed on the building are

transferred through the floor plates via diaphragm action to the main concrete cores.

Rafael Viñoly Architects,

all

The upper main cable supports lightweight steel trusses spanning perpendicularly to

the adjacent cable, the trusses being 10 ft (3 m) on center down the slope of the roof,

above top right. Gable end facade hanger cables are tensioned against the main roof

cables, above top left. Each upper main cable spans from the anchorage weldment on

the bow frame over a central mast (increasing in height from frames 1 to 15) and down

to an anchorage weldment at the third floor of the stern frame, bottom.

English For Arch & Civil II

Prepared by : Indra Tj

77

Although the overall structure can be separated into distinct elements for the purpose of

discussion, it is important to emphasize that the structural interaction of all of the

elements is fundamental to the behavior of the structure as a whole. The main elements

are the foundations, the structural frame, and the roof structure.

The soil beneath the building is for the most part a mix of gravel and marl with fill in

areas to a depth of 60 ft (18.3 m). Because of its proximity to the river, the site had

historically been used for docks and railroads, resulting in the presence of many hidden

obstructions—large concrete foundations for the old elevated railway system, for

example—that required removal.

The ground investigation survey detailed the depth of rock strata as being between 50 and

70 ft (15.2 and 21.3 m), depending on location, and indicated that the strata were suitable

for piles or caissons. On the basis of the recommendations included in the ground

investigation report and the high column loads, a deep foundation system was developed.

An analysis was undertaken to decide between piles and caissons, and the latter were

chosen because the cost of the pile caps for large pile groups would have been

prohibitive.

The caissons primarily resolve the vertical gravitational loads generated from the

structure above. The caissons vary in diameter from 1 ft 6 in. (0.5 m) to 7 ft (2.1 m), the

larger caissons carrying up to 4,000 tons (3,629 Mg). Concrete grade beams spanning

between the caissons were used to accommodate external envelope conditions and

elevator pits.

The major frames to the north and south of the building on each of the 15 framing lines

are referred to respectively as bow and stern frames—so named because of their

resemblance to those parts of a ship. The configuration of this main frame is such that it

supports the main floors and serves as the anchorage mechanism for the main cable roof.

As a result of the loads induced by the roof structure, the members within these frames

are frequently beyond the capacity of domestically available rolled steel sections. This led

to the decision to detail plated W sections—often weighing in excess of 500 lb/ft (744

kg/m). The plating method was deemed preferable because the steel could be obtained

domestically, as opposed to using “jumbo” sections, which are available only overseas.

The total weight of steel used in the structure exceeds 18,000 tons (16,329.5 Mg). The

bow frames each weigh approximately 120 tons (108.9 Mg); the stern frames, 200 tons

(181.4 Mg).

A strut placed between the bow and stern frames is used to help resolve internal forces

developed by the roof structure. The steel strut is a fabricated plate box girder weighing

800 lb/ft (1,190 kg/m).

The framing between the bow and stern frames forming the floors generally takes the

form of deep rolled W sections, which in turn support concrete double tees on the stern

and the concrete and metal deck in the bow. Above the main stern frame the system

changes to a steel beam and post system—a more traditional approach. The floors at the

English For Arch & Civil II

Prepared by : Indra Tj

78

fourth and fifth levels comprise metal decks on steel beams and concrete cast to a

thickness of 61/4 in. (159 mm).

The rhythm of the main structural frames at 60 ft (18.3 m) on center resulted in the need

for a floor structure that could efficiently span these distances. Moreover, the requirement

for the second-floor exhibition space is particularly demanding in terms of the 350 psf

(16.76 kPa) live-load criteria. The solution devised to meet these demands, as well as

those relating to cost, scheduling, and ease of construction, was the use of precast double

tee sections, the double tees designed for high loadings at a depth of 36 in. (914 mm).

The tees are supported on the steel structure at every frame line. Deflections of the

structure during roof tensioning had to be incorporated into the detailing of the precise

double tees. Each tee had to effectively transfer shear between itself and the adjacent tee

while facilitating the axial shortening of the supporting beam. A simple folded plate shear

connector was developed by the team that offered a highly cost-effective solution to a

complex problem. The tees are topped with 3 in. (76 mm) of concrete to furnish the

required diaphragm action across the floor and to provide the finished surface.

To maximize the economic benefits of using precast concrete for the main second-floor

exhibition space, the decision was made to use precast-concrete columns and structural

members to form the floors between the stern frames.

Column-Free Exhibition Floor

Rafael Viñoly Architects

The cable structure proved to be

a more efficient means of

effecting clear spans over the

second-floor exhibition space

than a long-spanning steel truss

structure.

The

economic

rationale was that over a

distance of 300 to 350 ft (91.4

to 106.7 m) cable roofs become

very competitive mechanisms

for achieving long spans. This

was a driving factor of the

structural design, as was the

intention to weave suspension

bridge technology into the

design.

English For Arch & Civil II

Prepared by : Indra Tj

79

A main cable spans the distance between the bow and stern frames, with the frames

attached to the cable using large plate weldments. The main span of the roof varies

between 300 and 400 ft (90.9 and 121.2 m) along the length of the building. The cable

roof consists of an upper cable spanning from the anchorage weldment on the bow frame

over a central mast (increasing in height between frames 1 and 15) and down to an

anchorage weldment at the third floor of the stern frame. The upper main cable supports

lightweight steel trusses spanning perpendicularly to the adjacent cable, these trusses

being 10 ft (3 m) on center down the slope of the roof.

A standing seam stainless steel roof spans between the steel roof trusses to form the roof

surface. The upper cable is prevented from uplift by the action of the lower damping

cable. The lower cable is a reflected arch of the upper cable, each cable inducing tension

in the others by means of vertical “hanger” cables that initially serve as the mechanism by

which the main upper and lower cables are tensioned. The stiffness of the tensioned cable

truss limits the overall vertical deflections of the roof.

The gable ends of the building required a glass facade that would be able not only to

accommodate the large deflections experienced by the roof but also to deal with the

curving geometry between the building and the roof structure. The first of these

challenges was addressed by combining the mullions of the facade with the roof

structure. By dropping cables at every proposed mullion position and tensioning them

between the flexible structure and the rigid building structure, the live-load deflections of

the roof structure were reduced from 3 ft (0.9 m) to less than 6 in. (152 mm). Clearly this

was the major advantage of making the head gasket detailing significantly less complex.

The tensioned vertical hangers could then be used as the wind load support for the

facade’s glass panels. Since the facade panels are unitized, the detailing between adjacent

panels had to be such that the large out-of-plane deflections could be accommodated

without compromising the weather seal. This flexible cable wall, with its insulated glass

unitized panels, is a world first in that it offers a mullion-free glass wall spanning a large

distance.

English For Arch & Civil II

Prepared by : Indra Tj

A joint venture composed of the

Pittsburgh offices of Turner

Construction Company, P.J. Dick,

Inc., and Advanced Technology

Systems, Inc., managed the

construction of the convention

center. The SEA had requested a fasttrack procurement process, and the

design team accommodated this

request through staged bid packages.

With respect to the structure, these

packages were for deep foundations,

foundation concrete (caisson caps),

structural steelwork, precast

concrete, cast-in-place concrete, and

the cable roof. The first of these

packages was put out for bid prior to

the completion of the design

development phase. The subsequent

letting of contracts for the structural

steelwork and roof structure prior to

the completion and coordination of

the structural documents led to

complex management and control of

the design evolution by both the

design and construction management

teams.

80

Rafael Viñoly Architects

The major frames to the north and south of the building

on each of the 15 framing lines—the bow and stern

frames—support the main floors and serve as the

anchorage mechanism for the main cable roof. Starting

from the bow frame, shown here, the elevation

increases.

The complexity of the cable roof and the interaction of the roof with the steel frame to

which it is anchored had to be overcome by erection engineering. A time history

computer analysis of the roof-tensioning procedure—including the deflections of the

anchorage frames—was set up by Philip Khalil, a project structural designer for

Dewhurst Macfarlane and Partners, in association with Goldreich Engineering PC. This

analysis tool allowed the structural designers to model each stage of the roof tensioning

and the associated frame deflections. By comparing the predicted deflections of the

anchorage frames at various points during the tensioning, it was possible to make

adjustments. This ability to make the required realignment adjustments was built into the

frame design. The analysis, review, and implementation of this process proved extremely

effective and accurate given the size of the roof structure and the loads being generated

through it.

English For Arch & Civil II

Prepared by : Indra Tj

81

Despite the complexity of the structural erection, the project schedule—and budget—

were adhered to, and the convention center opened to great acclaim on September 20.

The landmark convention center gracing the city’s waterfront stands as an eloquent

testament to the city’s engineering legacy and sets new standards for convention center

design.

James O’Callaghan, CENG, MIStructE, a senior associate, served as the project design

manager for the New York offices of Dewhurst Macfarlane and Partners, in association

with Goldreich Engineering PC.

CE Magazine Table of Contents | ASCE Publications Home Page | ASCE Home Page

Copyright © 2003 ASCE. All rights reserved.

NOVEMBER 2003 CIVIL ENGINEERING MAGAZINE

A. READING & UNDERSTANDING

Please read the each paragraph of above READING first then try to understand

clearly, after that you may make a statement with your own words describing the

paragraph that you just read.

( The student could be divided into groups, each group may do the statement

differently, after they finished, the lecturer may asked each group of student to read in

order ).

B. TRANSLATION

Please translate your new statement ( from A ), into bahasa Indonesia.

C. GRAMMAR

This grammar is continuation of the former chapter.

Untuk menyatakan suatu perbuatan yang telah terjadi, dan hubungan dengan suatu

waktu tertentu ( Past, Present, atau Future ) kita pakai “perfect” tenses : Present

Perfect, Past Perfect dan Future Perfect.

a. Present Perfect tense dipakai untuk menyatakan perbuatan yang telah terjadi

dalam waktu lampau, dihubungkan dengan waktu sekarang; atau yang terjadi pada

waktu lampau dan berlaku sampai sekarang.

English For Arch & Civil II

Prepared by : Indra Tj

82

Dibentuk dengan have/has + Past Participle ( Bagian Kata Kerja Ketiga ).

Example :

Where are Andy and Beth ?

They’ve gone to the movies.

What time did they go ?

They went about an hour ago.

Dimana Andy dan Beth ?

Mereka telah pergi ke bioskop.

Jam berapa mereka pergi ?

Mereka pergi kira-kira satu jam yang lalu.

I’ve cooked and cleaned and washed the dishes.

Saya sudah masak dan membersihkan rumah serta mencuci piring.

Mother has already cooked and cleaned and washed up.

Ibu telah selesai masak dan membersihkan rumah serta mencuci piring.

b. Untuk menyatakan suatu perbuatan yang telah selesai sebelum waktu tertentu

dalam waktu lampau, kita pakai bentuk Past Perfect Tense ( dibentuk dengan had

+ Bagian kata kerja ketiga ).

Example :

We had just gotten up when it began to rain.

Baru saja kita bangun disaat hari mulai hujan.

After the children had gone to the movies, I took a nap.

Sesudah anak-anak pergi ke bioskop, saya tidur sebentar.

c. Untuk menyatakan bahwa suatu perbuatan akan selesai ( terjadi ) pada suatu

waktu dalam waktu yang akan dating, kita pakai Future Perfect Tense. ( Dibentuk

dengan shall/will have + Kata Kerja Ketiga ).

Example :

Now they are still asleep, but by 7 o’clock they will gotten up.

Sekarang mereka masih tidur tetapi sebelum pukul 7 nanti, mereka akan bangun.

By the end of this month we will have gone to the movies four times.

English For Arch & Civil II

Prepared by : Indra Tj

83

Pada akhir bulan ini kita jadi empat kali pergi ke bioskop.

D.

NUMBERS

One

Two

Three

Four

Five

Six

Seven

Eight

Nine

Ten

-

first

second

third

fourth

fifth

sixth

seventh

eighth

ninth

tenth

Please continue by yourself.

A hundred

A hundred and one

-

hundredth

hundred and first.

A thousand

A million

A billion

A trillion

-

thousandth

millionth

billionth ( British ) = sejuta juta

trillionth ( American ) = sejuta juta

E. FRACTIONS

A half

A third

Two-thirds

A quarter/a fourth

Three-fourths

A fifth

Four-fifth

A tenth

A sixteenth

A twentieth

A hundredth

A thousandth

A millionth

-

setengah, separuh

sepertiga

dua pertiga

seperempat

tiga perempat

seperlima

empat perlima

sepersepuluh

seperenam belas

seperdua puluh

seperseratus

seperseribu

sepersejuta